Low voltage wiring – FloAire Electrical Controls User Manual

Page 9

A0023032

August 2014 Rev. 7

9

Low Voltage Wiring

Low voltage field wiring consists of Duct and Room Temperature sensors, ECM motors, 0-10VDC output,

24VDC input, or Modbus communication over CAT-5 cables for HMIs and remote equipment.

Additionally, panels can be ordered with Building Management Options. Refer to the Building

Management Owner’s Manual, if equipped, for low voltage building management wiring requirements.

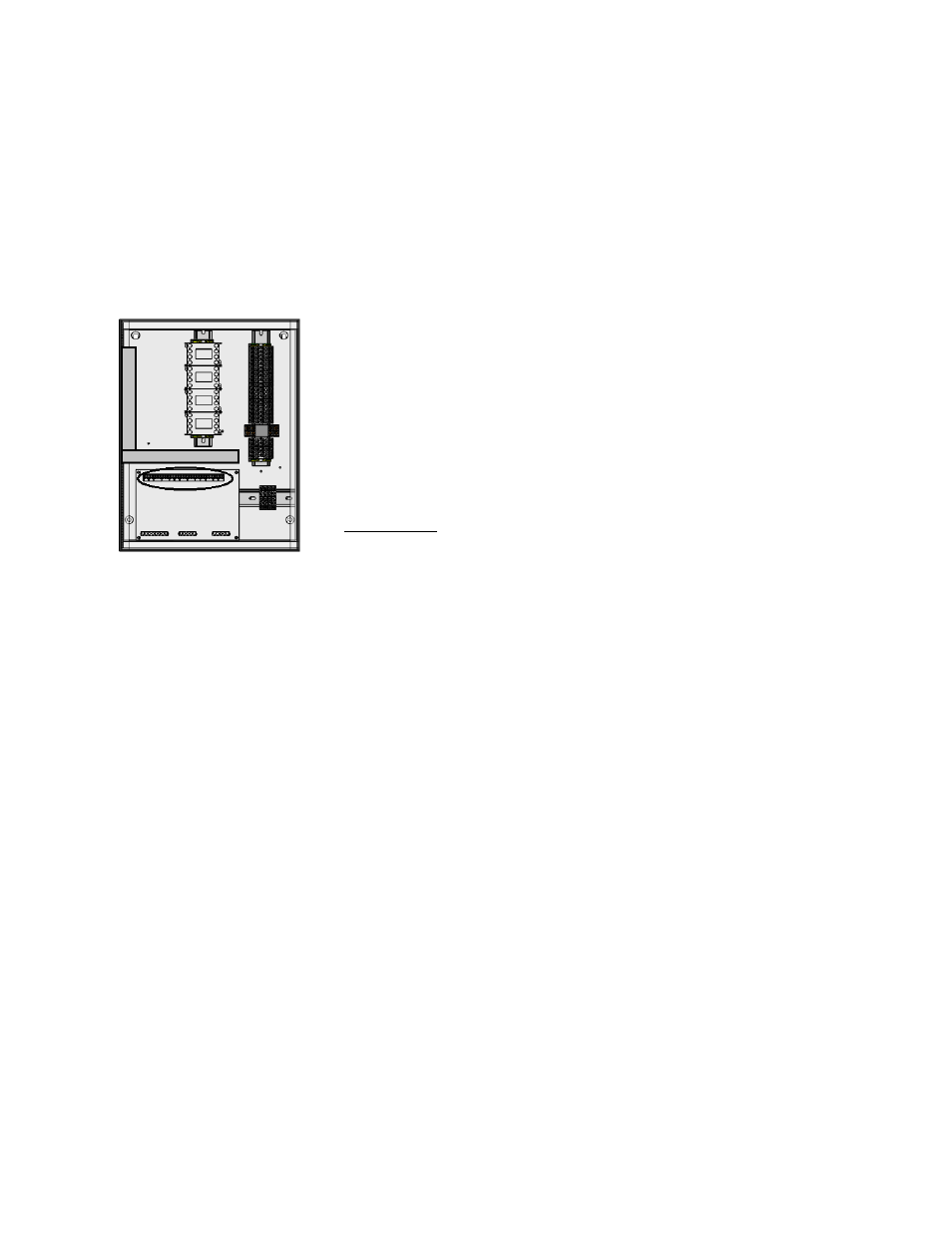

Low voltage wiring must be run through the wireway show below in the grey rectangle area. Wires will be

terminated on the terminals located on the ECPM03 board, circled below.

WARNING: Low voltage wires should never be run together with high voltage wires.

1- Room temperature sensor(s): For all installations utilizing duct

thermostats, at least 1 room temperature sensor must be installed in a

safe location, free of influence from external heat sources. It should be

indicative of the average kitchen temperature away from the appliances.

For packages with 2 separate fan zones, 1 or 2 room sensors can be

used. 2-wire 18 AWG thermistor cable must be used. The room

temperature sensor shall be wired according to the installation wiring

schematic, typically terminals “T1A”,”T1B”.

2- Duct temperature sensors: For all installations excluding a single

hood with factory risers and a hood mounted panel, duct mounted

temperature sensors will need to be wired in the field. 2-wire 18 AWG

plenum rated thermistor cable must be used. The temperature sensor

should be wired to terminal blocks as indicated on the installation wiring

schematic.

3- HMI(s) are connected to the ECPM03 board through CAT-5 cable. The HMI have two RJ-45

connectors connected together for Modbus.

a. If the panel was ordered with only 1 fan switch and/or 1 light switch, the HMI would connect

to port J4 (RJ-45) of the ECPM03 board. The other RJ-45 port of the HMI will typically be

occupied by a RJ-45 end-of-line terminator (Part # EOL120A).

b. If the panel was ordered and configured for 2 fan or 2 light switches, the first HMI would

connect to port J4 (RJ-45) of the ECPM03 board. The second HMI would connect to

ECPM03 board two ways:

o Connect the second HMI to the first HMI through CAT-5 cable. In this case the RJ-45

end-of-line terminator (Part # EOL120A) would only be used on the second HMI.

o Connect the second HMI to port J5 (RJ-45) of the ECPM03 Board. The other RJ-45

port of the HMI will typically be occupied by a RJ-45 end-of-line terminator (Part #

EOL120A).

4- Two end-of-line terminators (Part # EOL120A) are included in each panel. They are typically

plugged in at the factory on J3 and either on port J4 or in the back of the first HMI. If another HMI or

other equipment need to connect to a port occupied by an end-of-line terminator, it shall be removed

and place on the HMI or equipment that became connected at the end of the Modbus network.

NOTE: A third end-of-line terminator would be included with the package if the panel is ordered with 2

fan or 2 light switches. The extra end-of-line terminators will be mounted on the second HMI, if

decided to connect the HMI to J5. Otherwise, if daisy chained both HMIs, the third-end-line terminator

should be mounted on J5.

5- If other pieces of equipment such as PCU Advanced Filter Monitoring (AFM) are connected to this

panel, a cat-5 cable will also be used to run the Modbus communication between these devices. The

cable would be plugged in port J3 of the ECPM03 board. The end-of-line terminators should then be

relocated from J3 to the empty RJ45 port of the PCU AFM module.