FloAire Electrical Controls User Manual

Page 26

A0023032

August 2014 Rev. 7

26

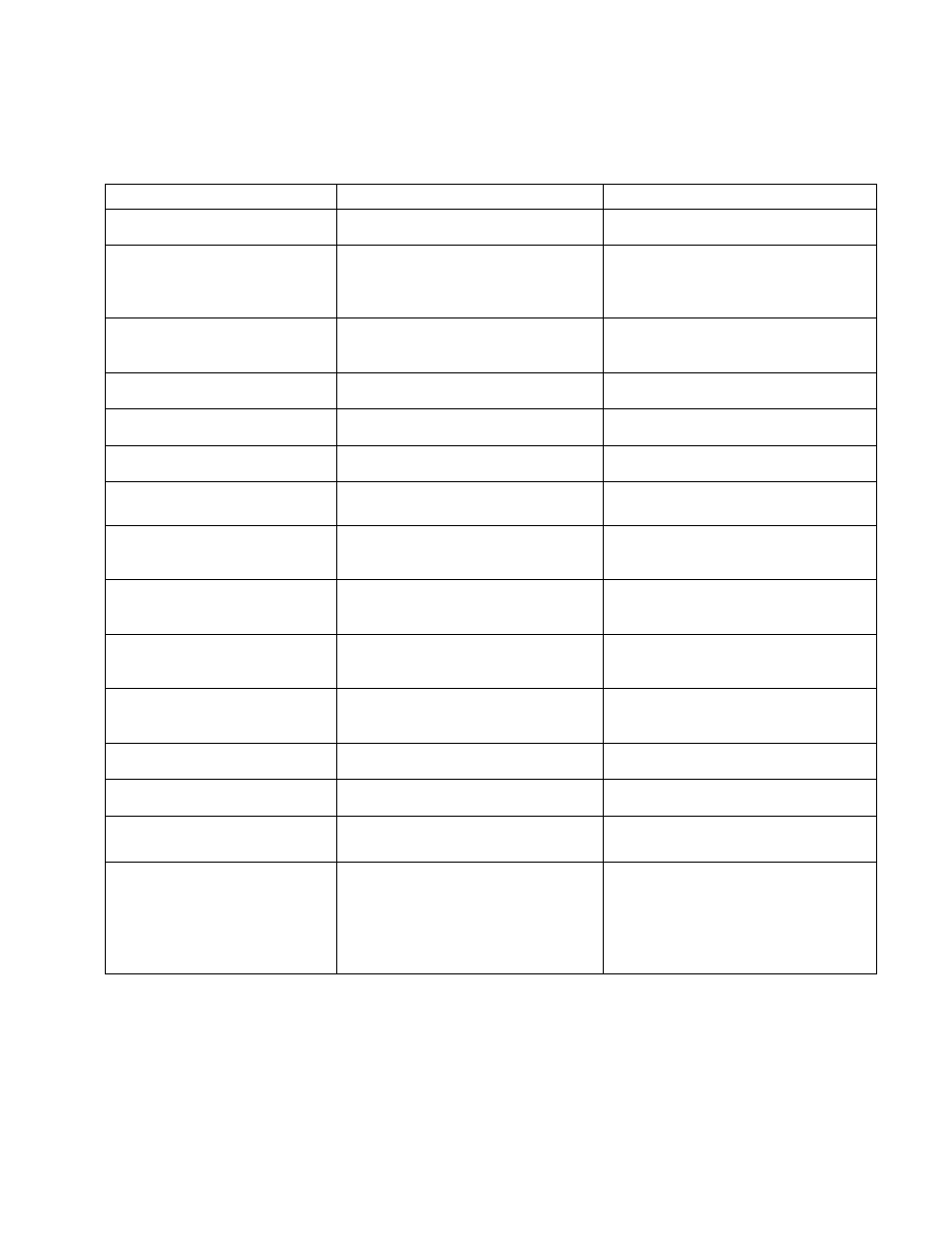

The following table lists Fault messages displayed on the HMI and corrective actions. Review this list prior

to consulting manufacturer.

Fault Message on HMI

Potential Cause

Corrective Action

“Fire”

FIRE or fire circuit not wired

properly.

If no fire, verify connection between

terminal blocks C1 and AR1.

“Equipment Disable

High Temp”

Duct temperature exceeded the

High Temp Equipment shutdown

Threshold and shut down the gas

valve and energizes the shunt trip.

Verify why Temp in duct is high.

Verify the Threshold value under

Configuration is set sufficiently high

(250 deg default).

“Light Fault Zone x

Bx De-

energized”

(x=1 or 2)

Light output is energized but no

power is detected on terminal Bx.

Verify that the light relay is not

damaged and that the light circuit

breaker is not tripped.

“Light Fault Zone x

Bx energized

” (x=1 or 2)

Light output is de-energized but

power is detected on terminal Bx.

Verify that the light relay contact is

not welded in the close position.

“Overload Trip

Zone

x” (x=1 or 2)

One of the overload relays for fans

associated with zone x is tripped.

Reset overload relay. Monitor fan to

see why overload tripped.

“Surfactant Low”

Surfactant level is low.

Refill Surfactant into the tank. Refer

to Self-Cleaning or CORE manual.

“PCU Fault”

PCU filters are clogged or missing.

Verify PCU filters and replace if

needed.

“Proving Fault”

Fan Proving Interlock enabled.

Exhaust fan not meeting its

minimum calibrated load.

Verify fans are running properly.

Verify Fan Proving calibration. Refer

to Fan Proving Interlock section.

“Fuse F1 Blown”

Fuse F1 is blown or missing

Replace fuse and verify there is no

short-circuit and load is below 4

amps.

“Temp Sensor x

Not Connected

”

Temperature sensor x is not wired

to the ECPM03 board.

Verify proper wiring to terminals TxA

and TxB on the board and wiring to

the sensor.

“Modbus Communication

Fault

”

One or several components on the

Modbus network are not

responding.

Verify HMIs are all plugged in. Verify

CORE or PCU AFM are plugged in if

configured as such.

“CORE x Fault”

Fault description

Specific fault is present on the

CORE fire system

Refer to the CORE manual for

specific fault description.

“PCU x Fault”

Fault description

Specific fault is present on the PCU

AFM x connected to the system.

Refer to the PCU AFM manual for

specific fault description.

“Temp Sensor x

Bad Sensor”

Bad Temp Sensor due to

overheating or internal failure

Replace the Temperature Sensor

“Communications fault

Check Configuration”

ECPM03 board and HMI not

communicating due to:

Software incompatible

Switchplate # doesn’t

match number of zones

Re-flash the HMI

Change switchplate #

Replace cat5 cable

Replace EOL