High voltage wiring, Electrical – FloAire Electrical Controls User Manual

Page 8

A0023032

August 2014 Rev. 7

8

Copper Wire Ampacity

Wire Size AWG

Maximum Amps

14

15

12

20

10

30

8

50

6

65

4

85

Electrical

Before connecting power to the control, read and understand

this entire document. As-built wiring diagrams are furnished

with each control by the factory and are attached either to the

door of the unit or provided within a paperwork pouch internal

to the panel.

Electrical wiring and connections should be done in

accordance with local ordinances and the National Electric

Code, ANSI/NFPA70. Be sure the voltage and phase of the

power supply and the wire amperage capacity is in accordance

with the unit nameplate.

1. Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

2. Make certain that the power source is compatible with

the requirements of your equipment. The installation

wiring schematic identifies the proper phase and

voltage of the source breakers.

3. Before connecting control to power source, verify

power line wiring is de-energized.

4. Secure all wiring to prevent contact with sharp objects.

5. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

6. Before powering up the system, make sure that the interior of the control is free of loose debris,

metal shavings, or shipping materials. `

7. If any of the original wire supplied with the system must be replaced, it must be replaced with type

THHN wire or equivalent.

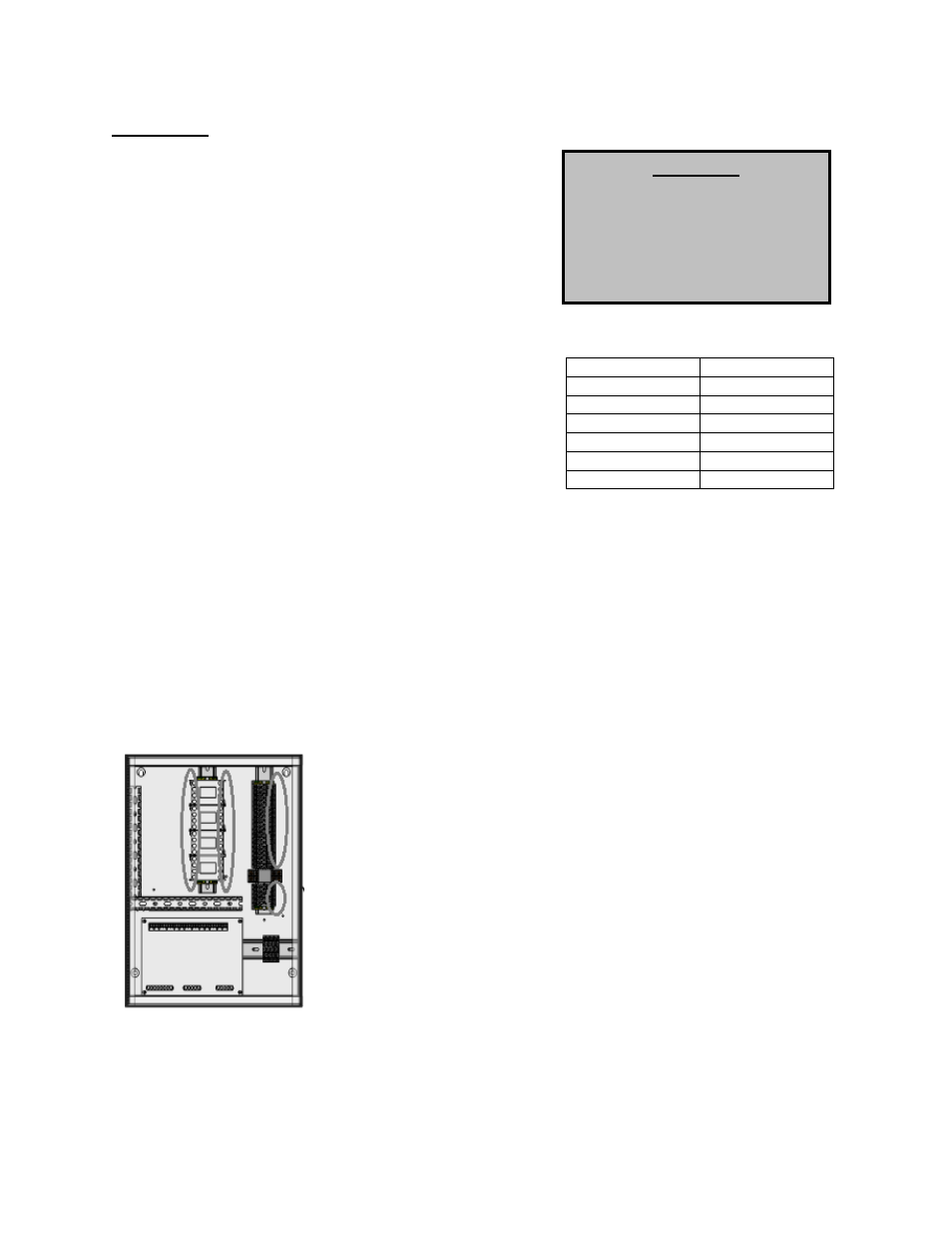

High Voltage Wiring

1. All high voltage wiring shall be terminated on the right side of the

terminal blocks or directly on the starters as designated in the

circled areas on the left hand diagram.

2. There are multiple electrical connections required for this

control. 120VAC should be wired to terminals H1 and N1. Input

power to the motors should be wired to

“L” series terminals. Motor

output power should be connected to

“T” terminals on the starters.

3. The hood light wiring will also need to be wired to terminals as

indicated on the installation diagram.

4. If an ANSUL fire system is present, the fire system micro-switch will

need to be wired to terminals as indicated on the installation

diagram, typically

“C1”, “AR1”. C1 is the common and connects to

terminal 1 on the micro-switch. AR1 is the armed state and

connects to terminal 2 on the micro-switch. If a CORE fire system is

present, this connection is not required.

WARNING!!

Disconnect

power

before

installing or servicing control.

High voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.