14 free-cooling management – EVCO c-pro nano CHIL User Manual

Page 119

C-PRO NANO CHIL AND C-PRO MICRO CHIL – APPLICATION MANUAL

Pag. 119

6.14

Free-Cooling Management

In order to achieve substantial energy savings in plant management, the chiller has the capability of

using external air – when this has favourable thermal properties – to exploit its energy content and

to obtain the cost-free chilling which is known as “free-cooling”.

On free-cooling machines, a water battery is usually mounted in front of the condensing battery, so

that the air first travels through this battery and then through the condensing battery. When the

external air temperature is lower than the water temperature (thus making it possible to cool the

water at the expense of the external air), the water (or glycol mixture) which enters the machine is

diverted to the water battery via a three-way valve, or via a dedicated pump, before passing through

the evaporator.

The possibility also exists of having a separate free-cooling circuit, with dedicated fan (PG13=1); in

this case, its is possible to achieve optimum condensation control, even while compressors are ON,

simultaneously regulating the free-cooling ventilation.

6.14.1

Free-Cooling Enable

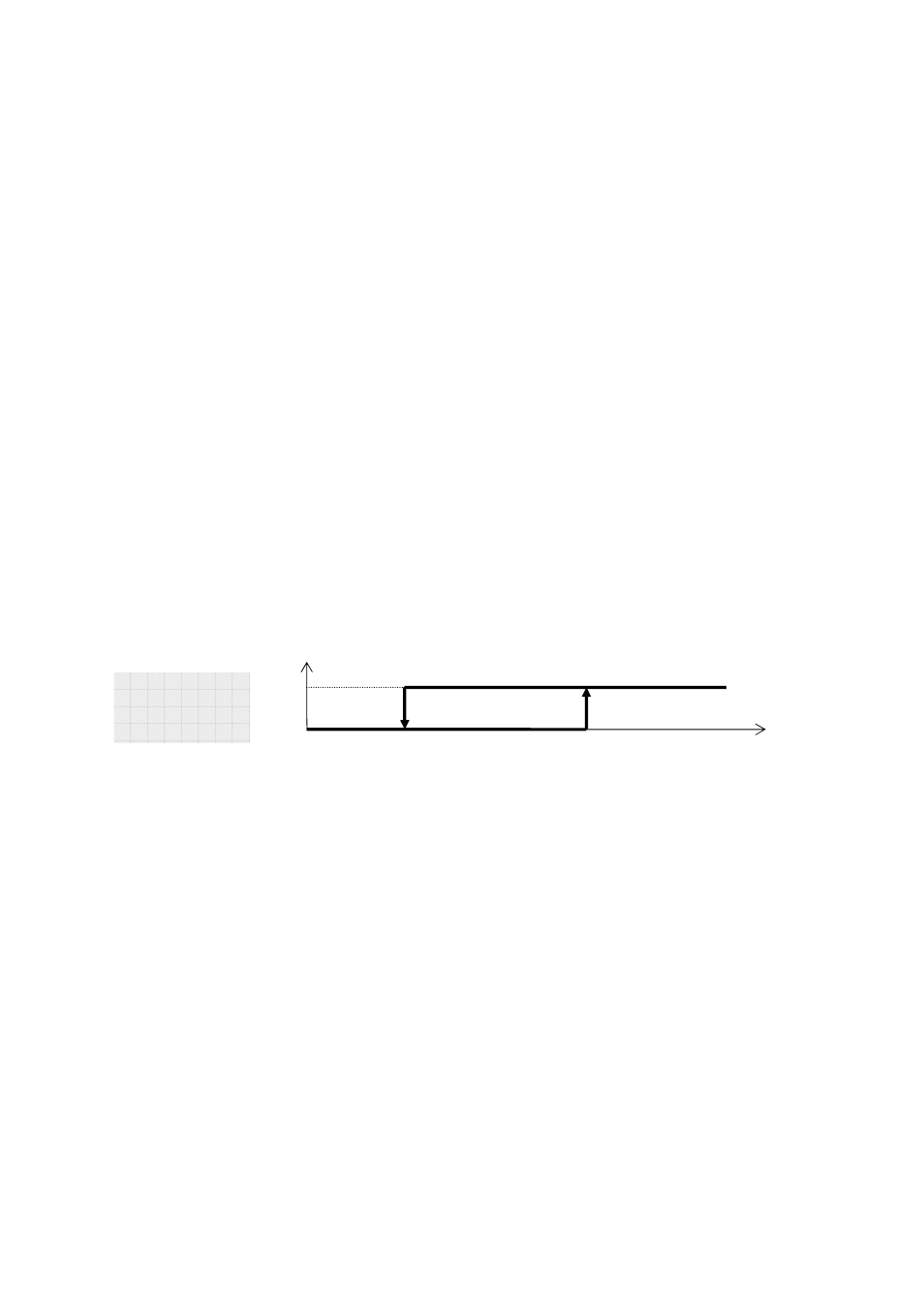

If it has been configured by parameter PS01, the free-cooling function (FC) for cost-free chilling is

enabled when the free-cooling ∆T (i.e. the difference between the water temperature [wT] and the

external air temperature [aT] that hits the free-cooling exchanger) reaches the set point value

(SetFC, parameter PS11). In order to avoid the risk of fluctuations in free-cooling enable status, it is

also possible to set a differential (DiffFC, parameter PS13).

The step condition must persist at least for the Enable minimum time PS14 (default value = 30

seconds), before enabling/disabling of free-cooling.

In case of a fault in the external temperature probe, free-cooling is disabled and the free-cooling

control valve is deactivated.

Free-cooling devices will also be switched OFF in case of intervention of the anti-frost heating

coils, and even more so in case of the associated alarm being triggered.

Other system protection devices or events – such as a break in the regulating probe, a break in the

anti-frost control probe, an evaporator flow meter alarm, or a circulating pump thermal protection

event – cause the unit to be switched OFF, thus also stopping free-cooling control.

6.14.2

Free-cooling regulation

By enabling free-cooling, it is possible to activate proportional regulation of fan speed.

Reference for free-cooling regulation is always the return temperature. Whether compressor

regulation is on the input (lateral band) or on the output (neutral zone), the free-cooling set point

always corresponds to the set point for user-load regulation.

SetFC-DiffFC SetFC

1

0

aT – eT

1 = F.C. On

0 = F.C. Off