EVCO ECK256J220S001 User Manual

Page 3

3

1 '96

It i possible to terminate a function by:

- pressing START/STOP key for more than one second; in this way the control unit is forced to "STOP" status

- pressing the MELT key for more than ine second, if the control unit is set to switch automatically to "conservation" phase

at the end of the function; in this way the P.I.D. control will become active until the required temperature has been reached.

The function will be automatically terminated when the Melt threshold has been reached.

Conservation (to maintain a constant oil temperature). Available parameters: b2, b3, b4, b7, P0, PI, Pb, Pc, Pd.

The “conservation” function enables the unit to maintain the oil temperature at the Melt setpoint to avoid the fat becoming dense again before

frying; a P.I.D. temperature control is active during this phase.

The “conservation” phase can be activated:

- by pressing the MELT key for more than one second during STOP status or “pre-heat” function; in both cases the control unit

will automatically switch to “conservation” at the end of a “pre-heat” phase.

- by pressing the MELT key for more than one second during “main control” function; in this case the unit will continue the P.I.D.

temperature control to reach the Melt threshold instead of the standard operating setpoint, and then it will automatically switch

to “conservation” function.

- automatically at the end of a “pre-heat” phase.

When the control unit terminates the “pre-heat” to start the “conservation” phase, the buzzer gives a specific signal for the time set by parameter

b7 (it is necessary to restart the control unit to enable this function after the Melt threshold has been changed). As soon as the temperature

measurement is higher than the Melt threshold, the MELT LED will remain lit for the duration of the “conservation” phase.

Parameter b3 is used to define a temperature band for the Melt threshold: when the temperature measurement is within this band, the START/

STOP LED, which had been flashing until then, will be lit to indicate that the oil temperature is approaching the desired value. Parameter b4 can

be used to delay the flashing of the START/STOP LED that indicates that the temperature measurement is no longer within the band set by

parameter b3.

It is possible to terminate the “conservation” phase and start the “main control” phase by pressing the MELT key for more than one second.

If the control unit has not been set to switch to “conservation” after a “pre-heat” phase has been completed, then it will automatically switch

to “main control” when the Melt threshold has been reached.

Main control. Available parameters: r1, r2, b3, b4, b7, P0, PI, Pb, Pc, Pd.

The “main control” function is used to increase the oil temperature to the desired value in the deep fryer sump with the accuracy of P.I.D. control.

The control unit switches to this function in the following cases:

- when a “conservation” phase has terminated.

- by pressing the START key for more than one second when the unit is in “STOP” status and a “pre-heat” or “conservation”

function has not been set.

- when a “pre-heat” function has terminated and a “conservation” function has not been set.

When the control unit switches to “main control” phase, the MELT LED turns off and the START/STOP LED remains lid for the time set by

parameter b4. As soon as the temperature measurement has reached the setpoint, the buzzer gives a specific signal for the time set by parameter

b7 (it is necessary to restart the control unit to enable this function after the setpoint has been changed).

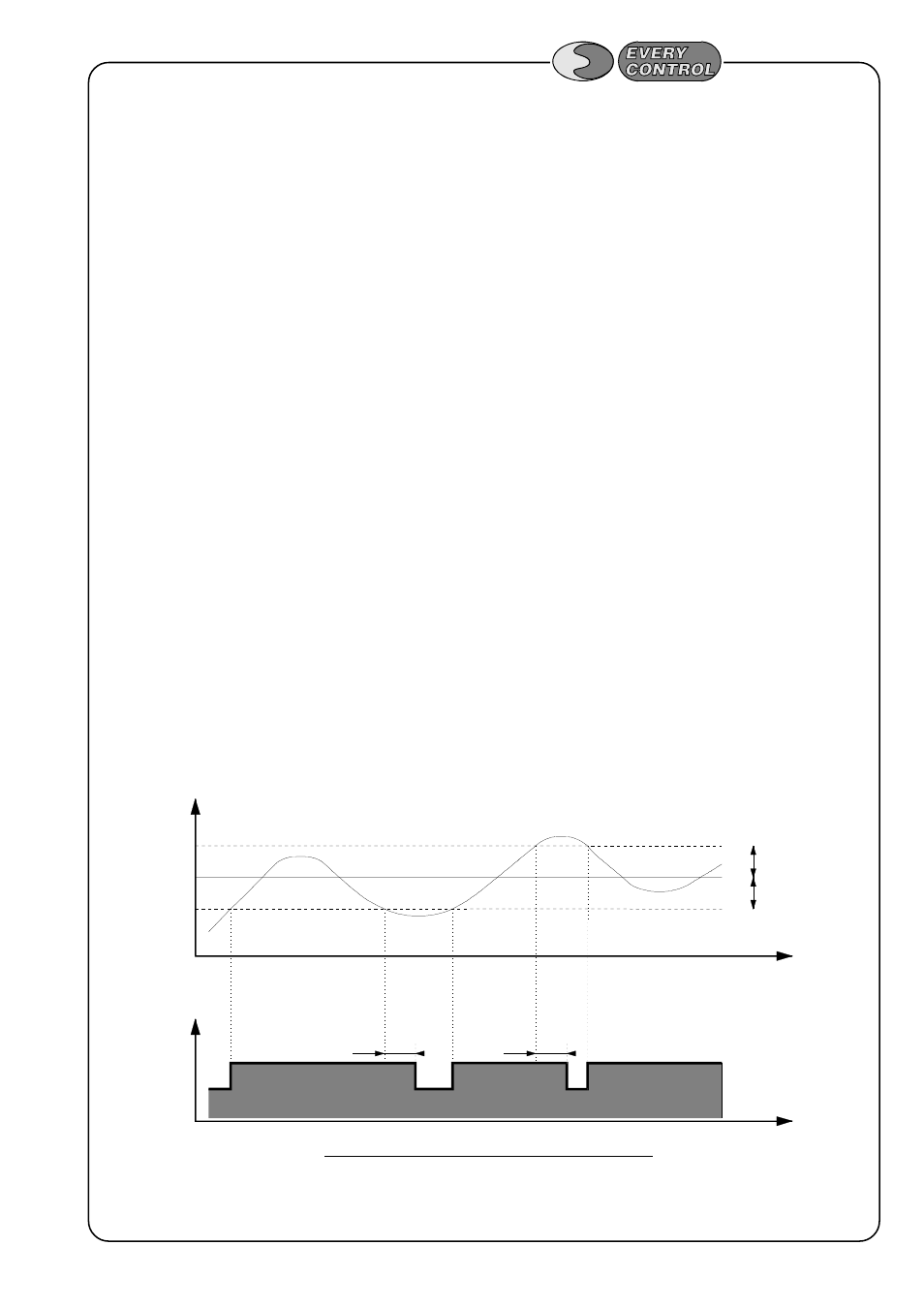

Like in the case of “conservation” phase, parameter b3 is used to define a temperature band for the main control setpoint: when the temperature

measurement is within this band, the START/STOP LED, which had been flashing until then, will be lit to indicate that the oil temperature is approaching

the desired value. Parameter b4 can be used to delay the flashing of the START/STOP LED that indicates that the temperature measurement is no

longer within the band set by parameter b3, which accounts for small temporary temperature differences like for instance when the basket is dipped

into the boiling oil.

oil

tem perature

tim e

b3

b3

w orking

setpoint

tim e

O N

FLA S H

O FF

S TA R T/STO P

led status

b4

b4

Fig. 3 - START/STOP LED status durin "main control" function