Antifreeze, Cooling tower/boiler systems, Operation power up mode – Carrier AQUAZONE 50VQP084-300 User Manual

Page 36

36

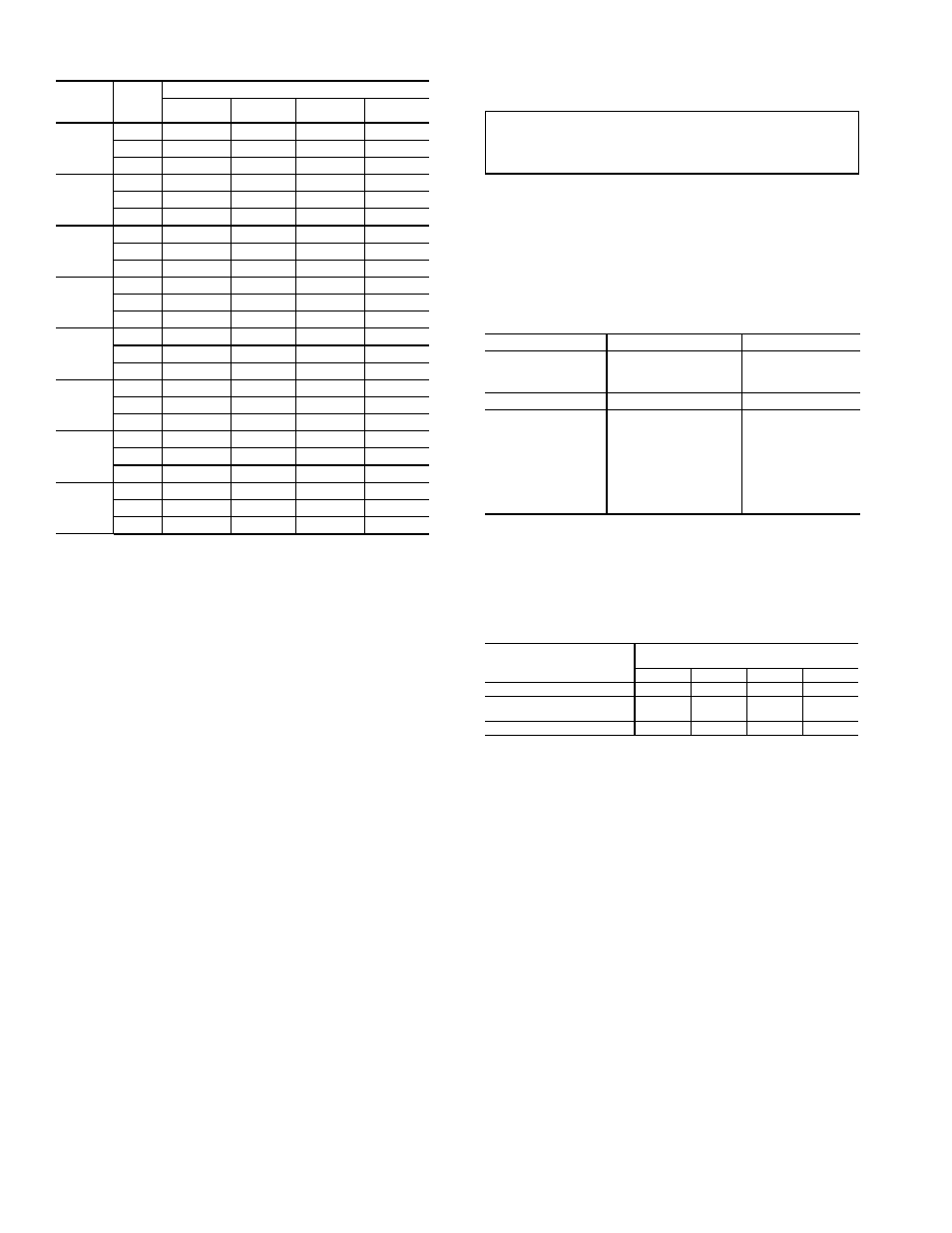

Table 17 — Coaxial Water Pressure Drop

NOTE: If air is purged from the system while using a

250 mm PVC flush tank, only a 25 to 50 mm level drop will

be noticed since liquids are incompressible. If the level

drops more than this, flushing should continue since air is

still being compressed in the loop. If level is less than 25 to

50 mm, reverse the flow.

8. Repeat this procedure until all air is purged.

9. Restore power.

Antifreeze may be added before, during or after the

flushing process. However, depending on when it is added

in the process, it can be wasted. Refer to the Antifreeze sec-

tion for more detail.

Loop static pressure will fluctuate with the seasons. Pres-

sures will be higher in the winter months than during the

warmer months. This fluctuation is normal and should be

considered when charging the system initially. Run the unit

in either heating or cooling for several minutes to condition

the loop to a homogenous temperature.

When complete, perform a final flush and pressurize the

loop to a static pressure of 275 to 350 kPa for winter months

or 100 to 140 kPa for summer months.

After pressurization, be sure to remove the plug from the

end of the loop pump motor(s) to allow trapped air to be

discharged and to ensure the motor housing has been flood-

ed. Be sure the loop flow center provides adequate flow

through the unit by checking pressure drop across the heat

exchanger.

Antifreeze —

In areas where entering loop temperatures

drop below 4.4 C or where piping will be routed through ar-

eas subject to freezing, antifreeze is needed.

Alcohols and glycols are commonly used as antifreeze

agents. Freeze protection should be maintained to 8.3° C below

the lowest expected entering loop temperature. For example, if

the lowest expected entering loop temperature is –1.1 C, the

leaving loop temperature would be –5.6 to –3.9 C. Therefore,

the freeze protection should be at –9.4 C (–1.1 C – 8.3 C =

–9.4 C) Calculate the total volume of fluid in the piping sys-

tem. See Table 18. Use the percentage by volume in

Table 19 to determine the amount of antifreeze to use. Anti-

freeze concentration should be checked from a well mixed

sample using a hydrometer to measure specific gravity. .

FREEZE PROTECTION SELECTION — The –1.1 C FP1

factory setting (water) should be used to avoid freeze damage

to the unit.

Once antifreeze is selected, the JW3 jumper (FP1) should

be clipped on the control to select the low temperature

(antifreeze –12.2 C) set point to avoid nuisance faults.

Table 18 — Approximate Fluid Volume (L)

per 30 M of Pipe

LEGEND

NOTE: Volume of heat exchanger is approximately 3.78 liters.

Table 19 — Antifreeze Percentages by Volume

Cooling Tower/Boiler Systems —

These systems

typically use a common loop maintained at 15.6 C to 32.2 C.

The use of a closed circuit evaporative cooling tower with a

secondary heat exchanger between the tower and the water

loop is recommended. If an open type cooling tower is

used continuously, chemical treatment and filtering will be

necessary.

Ground Coupled, Closed Loop and Plateframe

Heat Exchanger Well Systems —

These systems

allow water temperatures from –1.1 to 43.3 C. The external

loop field is divided up into 51 mm polyethylene supply and

return lines. Each line has valves connected in such a way

that upon system start-up, each line can be isolated for flush-

ing using only the system pumps. Air separation should be

located in the piping system prior to the fluid re-entering the

loop field.

OPERATION

Power Up Mode —

The unit will not operate until all

the inputs, terminals and safety controls are checked for

normal operation.

NOTE: The compressor will have a 5-minute anti-short

cycle upon power up.

50VQP

UNIT

SIZE

L/s

PRESSURE DROP (kPa)

–1 C

10 C

21 C

32 C

084

0.66

16.5

13.8

8.3

7.6

1.00

37.9

31.7

23.4

20.7

1.32

63.4

54.4

42.7

39.3

096

0.76

26.2

21.4

15.8

13.8

1.13

55.1

46.9

36.5

33.1

1.51

89.6

77.2

63.4

59.3

120

0.95

14.5

11.7

8.3

6.9

1.42

36.5

30.3

24.1

22.1

1.89

64.8

55.8

46.2

42.7

150

1.20

18.6

14.5

10.3

9.0

1.76

42.7

35.8

28.2

25.5

2.39

75.8

65.5

53.1

49.6

168

1.32

18.6

15.2

9.6

8.3

1.98

42.0

35.8

26.2

23.4

2.65

71.7

61.3

47.5

44.1

192

1.51

28.9

24.1

17.9

15.8

2.27

62.0

52.4

41.3

37.9

1.89

100.6

86.8

71.0

66.1

240

2.84

16.5

13.1

9.0

7.6

3.78

40.7

33.8

26.9

24.8

2.39

72.3

63.4

51.7

48.2

300

3.53

21.4

16.5

11.7

10.3

4.79

48.2

40.7

31.7

28.9

3.78

85.4

73.7

59.9

55.8

IMPORTANT: All alcohols should be pre-mixed and

pumped from a reservoir outside of the building or intro-

duced under water level to prevent alcohols from fuming.

PIPE

DIAMETER (in.) [mm] VOLUME (gal.) [L]

Copper

1 [25.4]

4.1 [15.5]

1.25 [31.8]

6.4 [24.2]

1.5 [38.1]

9.2 [34.8]

Rubber Hose

1 [25.4]

3.9 [14.8]

Polyethylene

3

/

4

IPS SDR11

2.8 [10.6]

1 IPS SDR11

4.5 [17.0]

1

1

/

4

IPS SDR11

8.0 [30.8]

1

/

2

IPS SDR11

10.9 [41.3]

2 IPS SDR11

18.0 [68.1]

1

1

/

4

IPS SCH40

8.3 [31.4]

1

1

/

2

IPS SCH40

10.9 [41.3]

2 IPS SCH40

17.0 [64.4]

IPS

— Internal Pipe Size

SCH — Schedule

SDR — Standard Dimensional Ratio

ANTIFREEZE

MINIMUM TEMPERATURE FOR FREEZE

PROTECTION (C)

–12.2

–9.4

–6.7

–3.9

Methanol (%)

25

21

16

10

100% USP Food Grade

Propylene Glycol (%)

38

30

22

15

Ethanol (%)

29

25

20

14