Step 9 — field control wiring, Pre-start-up system checkout – Carrier AQUAZONE 50VQP084-300 User Manual

Page 17

17

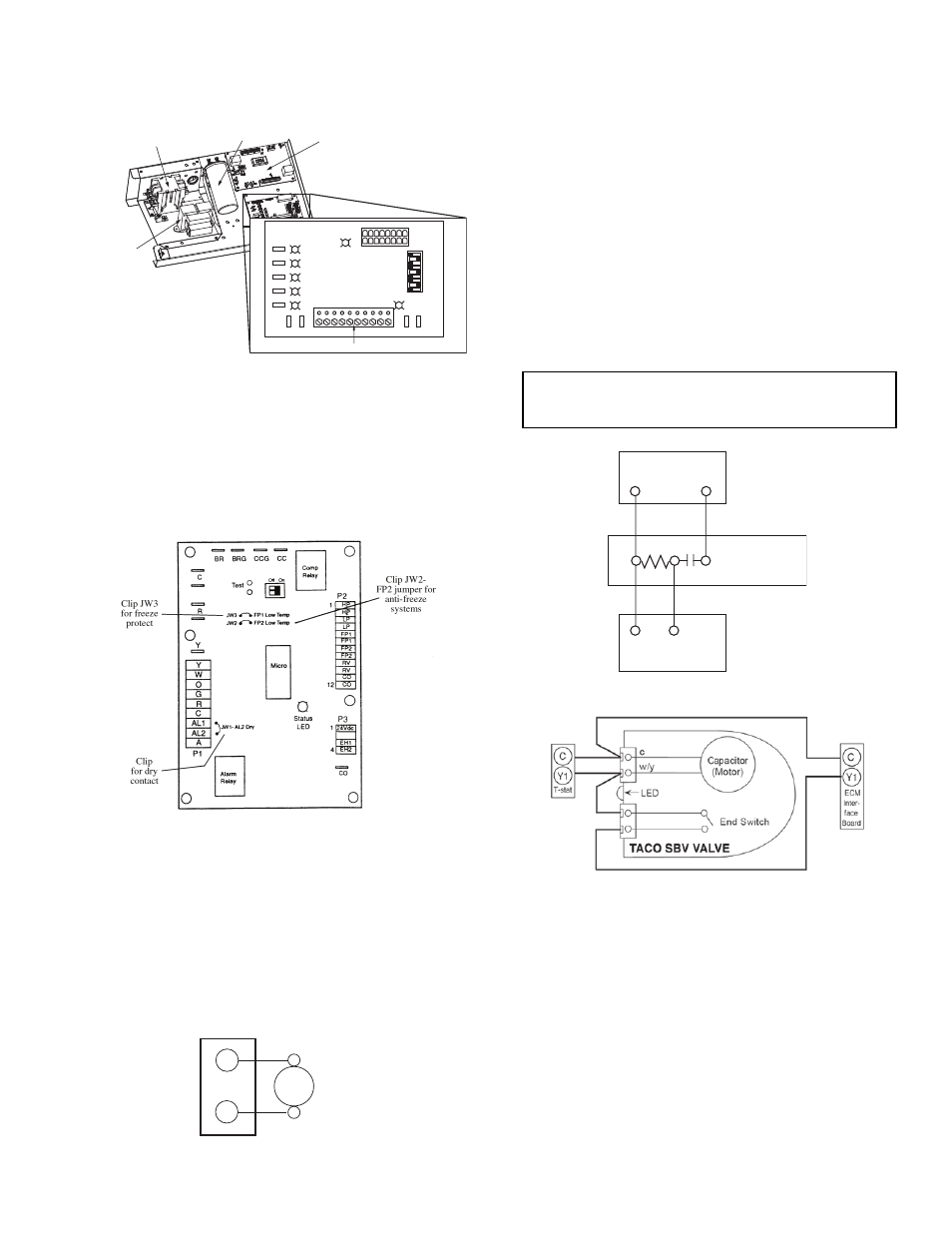

Step 9 — Field Control Wiring

THERMOSTAT CONNECTIONS — The thermostat should

be wired directly to the Aquazone™ control board. See

Fig. 27-31.

WATER FREEZE PROTECTION — The Aquazone control

allows the field selection of source fluid freeze protection

points through jumpers. The factory setting of jumper JW3

(FP1) is set for water at –1.1 C. In earth loop applications,

jumper JW3 should be clipped to change the setting to –12.2 C

when using antifreeze in colder earth loop applications. See

Fig. 32.

AIR COIL FREEZE PROTECTION — The air coil freeze

protection jumper JW2 (FP2) is factory set for –1.1 C and

should not need adjusting.

ACCESSORY CONNECTIONS — Terminal labeled A on

the control is provided to control accessory devices such as

water valves, electronic air cleaners, humidifiers, etc. This

signal operates with the compressor terminal. See Fig. 33.

Refer to the specific unit wiring schematic for details.

NOTE: The A terminal should only be used with 24 volt

signals — not line voltage signals.

WATER SOLENOID VALVES — An external solenoid

valve(s) should be used on ground water installations to shut

off flow to the unit when the compressor is not operating. A

slow closing valve may be required to help reduce water

hammer. Figure 33 shows typical wiring for a 24-vac external

solenoid valve. Figures 34 and 35 illustrate typical slow closing

water control valve wiring for Taco 500 Series and Taco ESP

Series valves. Slow closing valves take approximately 60 sec.

to open (very little water will flow before 45 sec.). Once fully

open, an end switch allows the compressor to be energized (on-

ly on valves with end switches). Only relay or triac based elec-

tronic thermostats should be used with slow closing valves.

When wired as shown, the slow closing valve will operate

properly with the following notations:

1. The valve will remain open during a unit lockout.

2. The valve will draw approximately 25 to 35 VA through

the “Y” signal of the thermostat.

PRE-START-UP

System Checkout —

When the installation is complete,

follow the system checkout procedure outlined below before

starting up the system. Be sure:

1. Voltage is within the utilization range specifications of the

unit compressor and fan motor and voltage is balanced

for 3-phase units.

2. Fuses, breakers and wire are correct size.

3. Low voltage wiring is complete.

4. Piping and system flushing is complete.

5. Air is purged from closed loop system.

6. System is balanced as required. Monitor if necessary.

7. Isolation valves are open.

8. Water control valves or loop pumps are wired.

Fig. 31 — Low Voltage Field Wiring

COMPLETE C CONTROL

CAPACITOR

LINE

LO

AD

COMPRESSOR CONTACTOR

TRANSFORMER

Y

GGGG

R

W

O

Y2

Y1

G

R

C

Y2 Y1 G

O W C R DH AL1 A

A

AL1

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9

OFF

ON

G DEHUM

CFM

TB1

J1

S1

THERMOSTAT CONNECTION

a50-8197

NOTE: Low voltage connector may be removed for

easy installation.

AQUAZONE CONTROL (Complete C Control Shown)

Fig. 32 — Typical Aquazone™ Control Board

Jumper Locations

a50-

6268tf.tif

TYPICAL

WATER

VALVE

C

A

24 VAC

TERMINAL STRIP P2

Fig. 33 — Typical Aquazone Accessory Wiring

(Control D Shown)

IMPORTANT: Connecting a water solenoid valve can

overheat the anticipators of electromechanical thermo-

stats. Only use relay based electronic thermostats.

Fig. 35 — Taco SBV Valve Wiring

Fig. 34 — AMV Valve Wiring

C

C

THERMOSTAT

1

Y

1

2

3

1

Y

AMV

TACO VALVE

HEATER SWITCH

a50-8441

a50-8442