Carrier AQUAZONE 50VQP084-300 User Manual

Page 34

34

Auto Dehumidification Mode or High Fan Mode — Switch 7

provides selection of auto dehumidification fan mode or high

fan mode. In auto dehumidification fan mode the fan speed

relay will remain off during cooling stage 2 if terminal H is

active. In high fan mode, the fan enable and fan speed relays

will turn on when terminal H is active. Set the switch to ON for

auto dehumidification fan mode or to OFF for high fan mode.

Switch 8 — Not used.

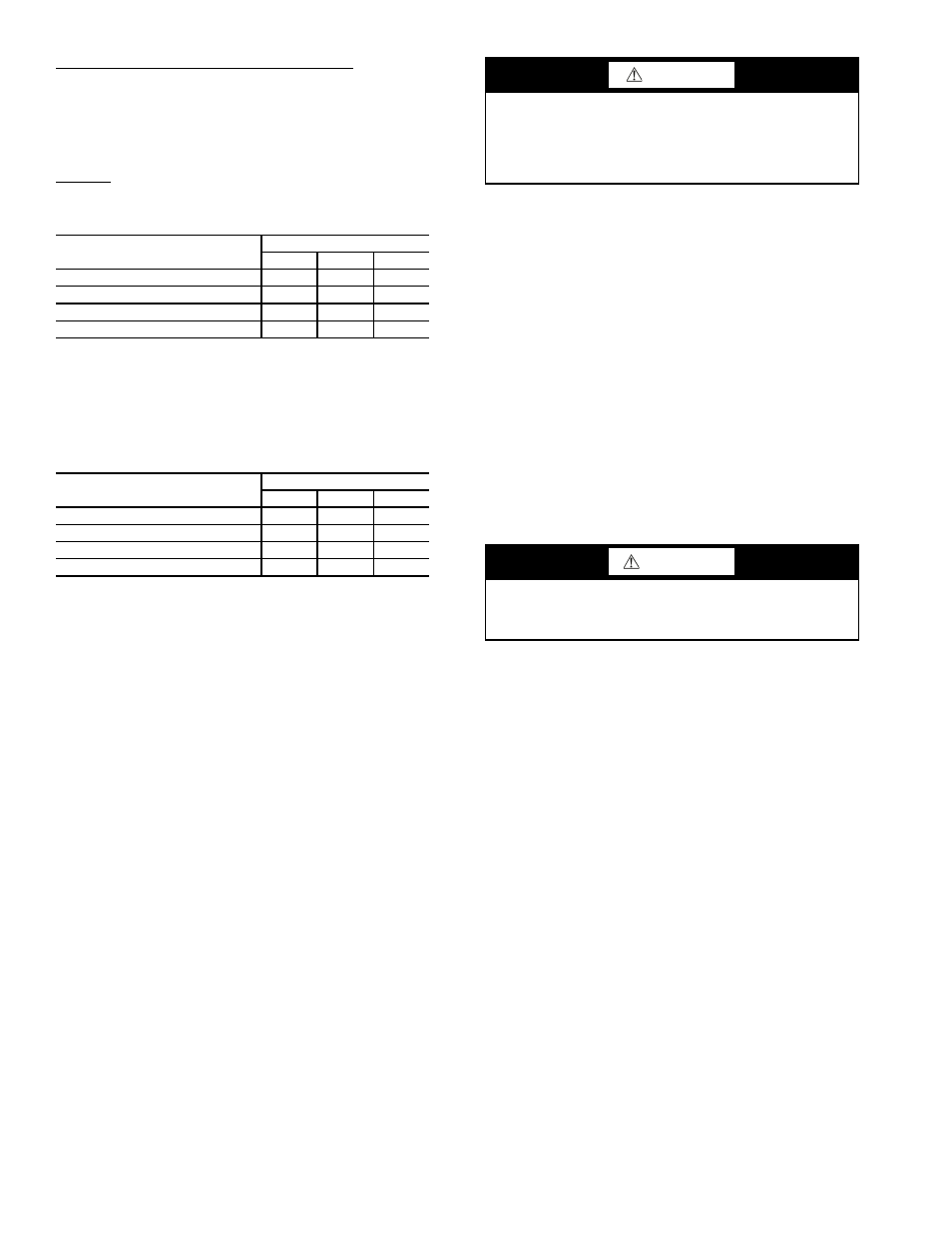

Table 13 — DIP Switch Block S2 —

Accessory 1 Relay Options

LEGEND

NOTE: All other DIP switch combinations are invalid.

Table 14 — DIP Switch Block S2 —

Accessory 2 Relay Options

LEGEND

NOTE: All other switch combinations are invalid.

Deluxe D Control Accessory Relay Configura-

tions —

The following accessory relay settings are applica-

ble for both Deluxe D controls only:

CYCLE WITH FAN — In this configuration, the relay will be

ON any time the Fan Enable relay is on.

CYCLE WITH COMPRESSOR — In this configuration, the

relay will be ON any time the Compressor relay is on.

DIGITAL NIGHT SET BACK (NSB) — In this configura-

tion, the relay will be ON if the NSB input is connected to

ground C.

NOTE: If there are no relays configured for digital NSB, then

the NSB and override (OVR) inputs are automatically config-

ured for mechanical operation.

MECHANICAL NIGHT SET BACK — When NSB input is

connected to ground C, all thermostat inputs are ignored. A

thermostat set back heating call will then be connected to the

OVR input. If OVR input becomes active, then the Deluxe D

control will enter Night Low Limit (NLL) staged heating

mode. The NLL staged heating mode will then provide heating

during the NSB period.

WATER VALVE (SLOW OPENING) — If relay is config-

ured for Water Valve (slow opening), the relay will start 60 sec-

onds prior to starting compressor relay.

OUTSIDE AIR DAMPER (OAD) — If relay is configured

for OAD, the relay will normally be ON any time the Fan

Enable relay is energized. The relay will not start for 30 min-

utes following a return to normal mode from NSB, when NSB

is no longer connected to ground C. After 30 minutes, the relay

will start if the Fan Enable is set to ON.

START-UP

Use the procedure outlined below to initiate proper unit

start-up.

NOTE: This equipment is designed for indoor installation only.

Operating Limits

ENVIRONMENT — This equipment is designed for indoor

installation ONLY. Extreme variations in temperature, humidi-

ty and corrosive water or air will adversely affect the unit per-

formance, reliability and service life.

POWER SUPPLY — A voltage variation of ± 10% of name-

plate utilization voltage is acceptable.

UNIT STARTING CONDITIONS — All units start and op-

erate in an ambient of 7.2 C with entering-air at 4.4 C, entering-

water at –6.7 C and with both air and water at the flow rates

used.

NOTE: These operating conditions are not normal or continu-

ous operating conditions. It is assumed that such a start-up is

for the purpose of bringing the building space up to occupancy

temperature.

Start Up System

1. Restore power to system.

2. Turn thermostat fan position to ON. Blower should start.

3. Balance airflow at registers.

4. Adjust all valves to the full open position and turn on the

line power to all heat pump units.

5. Operate unit in the cooling cycle. Room temperature

should be approximately 10 to 38 C dry bulb. Loop water

temperature entering the heat pumps should be between

10 and 49 F.

NOTE: Three factors determine the operating limits of a

unit: (1) entering-air temperature, (2) water temperature and

(3) ambient temperature. Whenever any of these factors are

at a minimum or maximum level, the other two factors must

be at a normal level to ensure proper unit operation. See

Table 15.

Scroll Compressor Rotation —

It is important to be

certain compressor is rotating in the proper direction. To

determine whether or not compressor is rotating in the proper

direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

ACCESSORY 1

RELAY OPTIONS

DIP SWITCH POSITION

1

2

3

Cycle with Fan

On

On

On

Digital NSB

Off

On

On

Water Valve — Slow Opening

On

Off

On

OAD

On

On

Off

NSB — Night Setback

OAD — Outside Air Damper

ACCESSORY 2

RELAY OPTIONS

DIP SWITCH POSITION

4

5

6

Cycle with Fan

On

On

On

Digital NSB

Off

On

On

Water Valve — Slow Opening

On

Off

On

OAD

On

On

Off

NSB — Night Setback

OAD — Outside Air Damper

CAUTION

To avoid equipment damage, DO NOT leave system filled

in a building without heat during the winter unless anti-

freeze is added to system water. Condenser coils never

fully drain by themselves and will freeze unless winterized

with antifreeze.

WARNING

When the disconnect switch is closed, high voltage is

present in some areas of the electrical panel. Exercise

caution when working with the energized equipment.