Troubieshooting, Troubleshooting – Kenmore 385.162213 User Manual

Page 108

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Troubieshooting

For customer assistance call or e-mail:

1-877-SEWING-U (1-877-739-4648)

9 am - 4:30 pm, CST, Monday - Friday

96

f

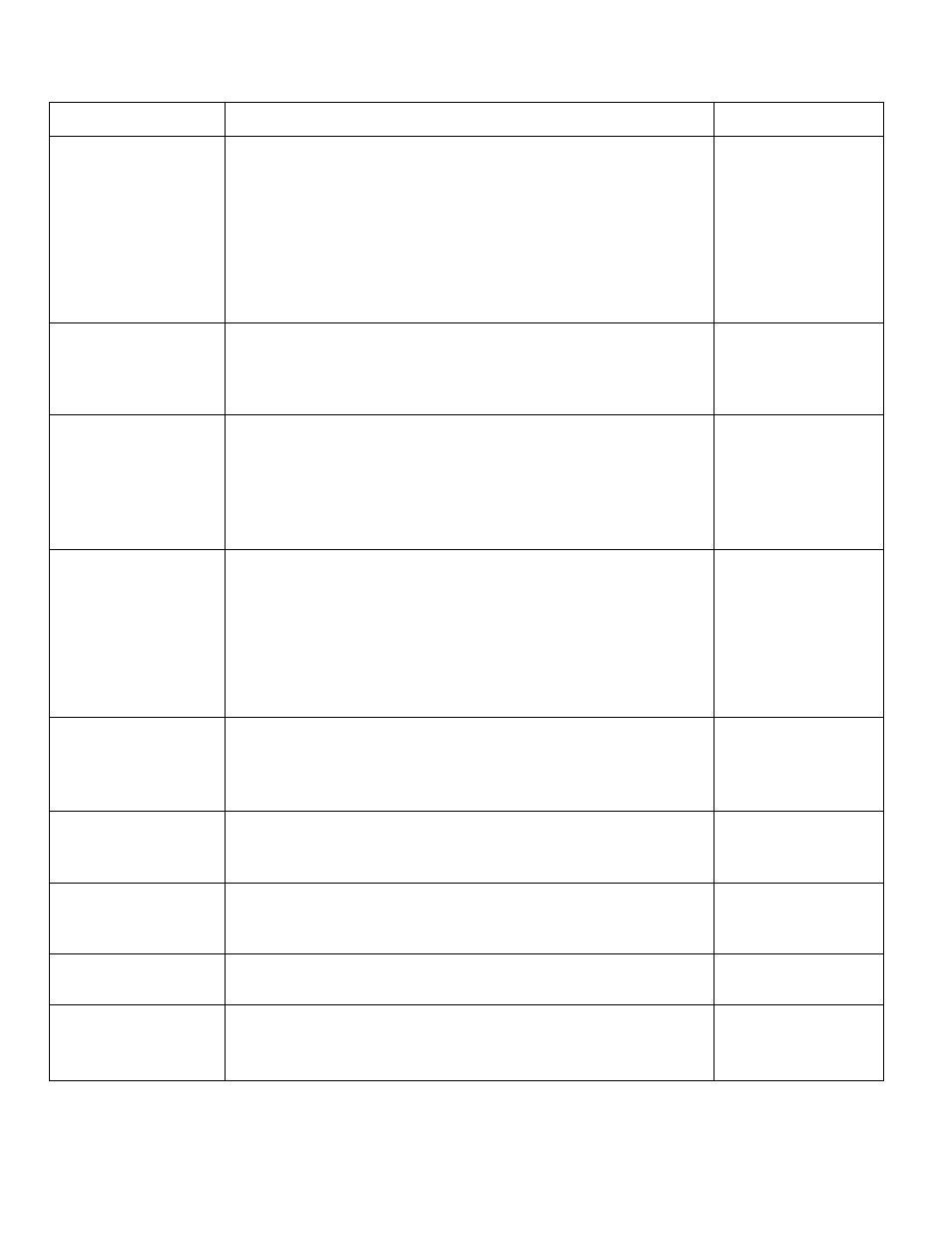

Condition

Cause

Reference ^

The needle thread

1 The needie thread is not threaded properly.

Page 26

breaks.

2. The needle thread tension is too tight.

Pages 28,30

3. The needle is bent or blunt

Page 10

4. The needle is incorrectly inserted

5, The needle thread and the bobbin thread are not set property

Page 10

under the presser foot at the start of sewing.

Pages 28, 38

6

, The threads were not drawn to the rear after the previous use,.

Page 38

7. The thread is too heavy or too fine for the needie.

Page 16

The bobbin thread

1, The bobbin thread is not threaded properly in the bobbin holder.

Page 24

breaks.

2„ Lint has collected in the bobbin holder.

Page 92

3. The bobbin is damaged and doesn't turn smoothly

Change the bobbin

The needle breaks.

1. The needle is incorrectly inserted

Page 10

2. The needle is bent or blunt.

Page 10

3., The needle damp screw is loose.

Page 10

4. The needle thread tension is too tight,

Pages 28,30

5. The threads were not drawn to the rear after the previous use.

Page 38

6

,, The needle is too fine for the fabric being sewn.

Page 16

Skipped stitches

1,. The needie is incorrectly inserted.

Page 10

2, The needle is bent or blunt.

3, The needle and/or threads are not suitable for the work being

Page 10

sewn

Page 16

4. A blue needle is not being used for sewing stretch, very fine

fabrics and synthetics.

Page 16

5., The needle thread is not threaded properly

Page 26

6

, The wrong needle is used.

Page 10

Seam puckering

1. The needle thread tension is too tight

Pages 28, 30

2, The needle thread is not threaded properly

Page 26

3. The needle is too heavy for the fabric being sewn.

Page 16

4, The stitch length is too long for the fabric.

Page 34

The cloth is not

1

, The stitches are too fine

Pages 28,30

feeding smoothly.

2. The feed dog is not raised after “drop feed’’ sewing.

Page 46

3. The feed dog is packed with lint.

Page 98

The machine

1

. The machine is not plugged in.

Page 6

doesn't work.

2. A thread is caught in the shuttle race.

Page 94

3, The push-clutch is disengaged.

Page 22

Patterns are

distorted.

1 The stitch is not balanced,

Page 36

Noisy operation

1, There is thread caught in the hook race.

Page 94

V

2 Lint has built up in the shuttle or the shuttle race.

Page 94

J