Carrier HS070-160 User Manual

Page 4

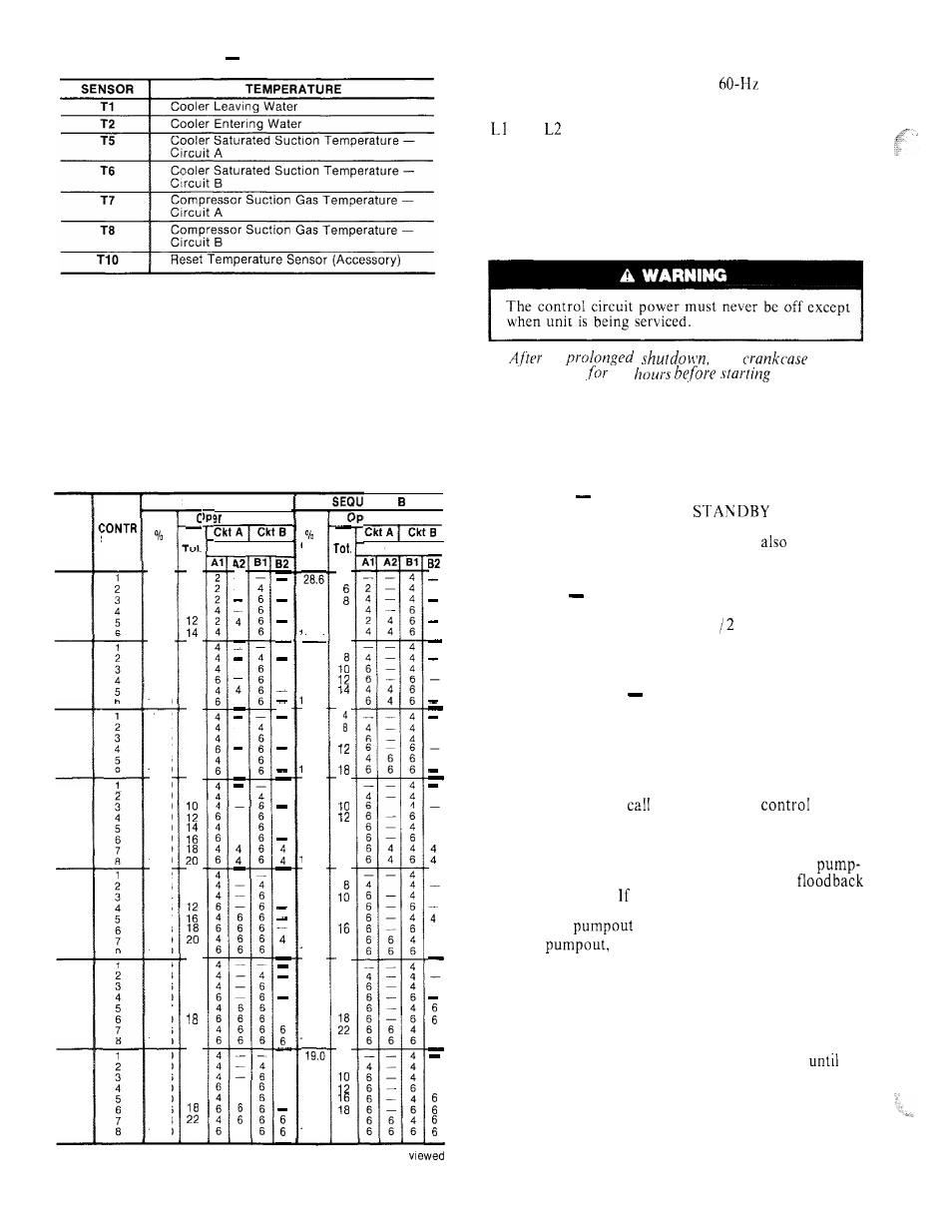

Table 3

Thermistors

CONTROL SEQUENCE

The control power (115-l-60 for

units; 230-l-50

for 50-Hz units) must be supplied directly from a separate

source through a code-approved fused disconnect to the

and

terminals of unit power teminal block.

NOTE: There is no switch or circuit breaker; only fuses. If

the control power feed is live, so is the circuit.

Crankcase heaters are wired into the control circuit.

They are always operative as long as control circuit

power is on even though unit may be off because of

safety device action. Heaters are wired so they are on only

when their respective compressors are cycled off.

a

the

heaters

should be on

24

the unit.

When power is supplied to control circuit, unit is ready

for operation providing all safety devices are satisfied,

interlocks are closed and instructions on warning labels

have been followed.

If schedule function is used, refer to page 11 for details

on control operation.

Off Cycle

During unit off cycle when the RUN;

STANDBY switch is in the

position, the

crankcase heaters and the control system are energized.

The electronic expansion valves are

energized.

(NOTE: The control circuit power must be on at all times

even when the main unit power is off.)

Start-Up

When the RUN/STANDBY switch is

moved from the STANDBY to the RUN position and

there is a call for cooling, after l-l

to 3 minutes have

passed the first compressor will start unloaded, The first

circuit to start may be circuit A or B due to the automatic

lead/ lag feature.

Capacity Control

(See Table 4.) The rate at which

the compressors are turned on will depend on the leaving

water temperature difference from the set point, the rate

of change of leaving water temperature, the return water

temperature and the number of compressor stages on.

The control is primarily from leaving water temperature

and the other factors are used as compensation.

SEQUENCE -- On a

for cooling, the

system

starts the initial compressor. The control will randomly

select either circuit A or B. The liquid line solenoid valve

remains closed for 10 seconds after the initial compressor

on that refrigeration circuit starts. This permits a

out cycle at start-up to minimize refrigerant

to the compressor. the compressor in that refrigeration

circuit has run in the 15 minutes before the call for

cooling, the

cycle is bypassed.

After

the liquid line solenoid valve opens and

the electronic expansion valve starts to open.

The electronic expansion valve will open gradually to

provide a controlled start-up to prevent liquid floodback

to the compressor. Also during this period, the oil pres-

sure switch will be bypassed for one minute.

As additional cooling is required, the control system

will ramp up through the capacity steps available

the

load requirement is satisfied. As capacity steps are added

compressors are brought on line, alternating between the

lead and lag refrigerant circuits. As explained previously,

the speed at which capacity is increased or decreased is

controlled by the temperature deviation from the set

point and the rate of change in the chilled water

temperature.

Table 4

Capacity Control Steps

SEQUENCE A

ENCE

er Cylinders

2

6

a

1 0

4

a

1 0

1 2

1 4

1 6

4

a

1 0

1 2

1 6

1 8

4

8

4

a

10

2 2

4

a

1 0

1 2

1 6

2 2

2 4

4

a

1 0

1 2

1 6

2 4

4

1 0

1 2

1 4

4

1 6

1 0

1 6

4

a

1 4

1 6

1 8

2 0

4

1 2

1 4

2 0

2 2

4

a

1 0

1 2

1 6

2 4

4

8

2 2

2 4

Cylinders

C o m p r

4

4

6

6

4

4

6

6

4

UNIT

3 0 H R

3 0 H S

STEPS

C a p .

1 4 . 3

4 2 . 9

5 7 . 2

7 1 . 2

8 5 . 7

100.0

2 5 . 0

5 0 . 0

6 2 . 5

7 5 . 0

8 7 . 5

100.0

Cap.

4 2 . 9

5 7 . 2

7 1 . 2

8 5 . 7

0 0 . 0

2 5 . 0

5 0 . 0

6 2 . 5

7 5 . 0

8 7 . 5

0 0 . 0

2 2 . 2

4 4 . 4

5 5 . 5

6 6 . 7

8 8 . 8

‘00.0

2 0 . 0

4 0 . 0

5 0 . 0

6 0 . 0

7 0 . 0

80.0

9 0 . 0

100.0

18.2

3 6 . 3

4 5 . 4

5 4 . 5

63.6

72.7

9 0 . 9

t 00.0

16.6

3 3 . 3

4 1 . 6

50.0

6 6 . 7

7 5 . 0

9 1 . 6

100.0

3 8 . 0

4 7 . 6

5 7 . 0

6 9 . 0

7 8 . 6

9 0 . 4

100.0

C o m p r

4

4

4

4

4

6

6

0 7 0

0 8 0

2 2 . 2

4 4 . 4

5 5 . 5

6 6 . 7

8 8 . 8

1 0 0 . 0

2 0 . 0

4 0 . 0

5 0 . 0

6 0 . 0

7 0 . 0

8 0 . 0

9 0 . 0

100.0

18.2

3 6 . 3

4 5 . 4

5 4 . 5

72.7

8 1 . 8

9 0 . 9

100.0

090

1 0 0

1 1 0

16.6

3 3 . 3

4 1 . 6

5 0 . 0

6 6 . 7

7 5 . 0

9 1 . 6

100.0

19.0

3 8 . 0

4 7 . 6

5 7 . 0

6 9 . 0

7 8 . 6

9 0 . 4

100.0

120,

1 6 0

1 4 0

NOTE: Circuits and

from front of unit.

compressors designated from ieft to right when

4