Carrier HS070-160 User Manual

Page 13

NOTE: The control does not detect circuit breaker

failures. If a circuit

trips on the lead compressor

in a circuit, a

pressure failure

be indicated;

on the other compressors, no failure

be indicated.

Shut off the main

power to the unit. Turn on control power, then step

through the Quick Test to the proper compressor number

(i.e., failure code

is

Next, energize the

step. If the step works correctly, then the failure code

is due to:

.

l

l

back wire from

strip to

strip

l

Ground wire and

feeds reversed on one or more

points on

The

ground wire

terminals 2, 4, 6 and 8. Feeds

compressors Al,

A2,

and

connect to pins I, 3, 5 and 7.

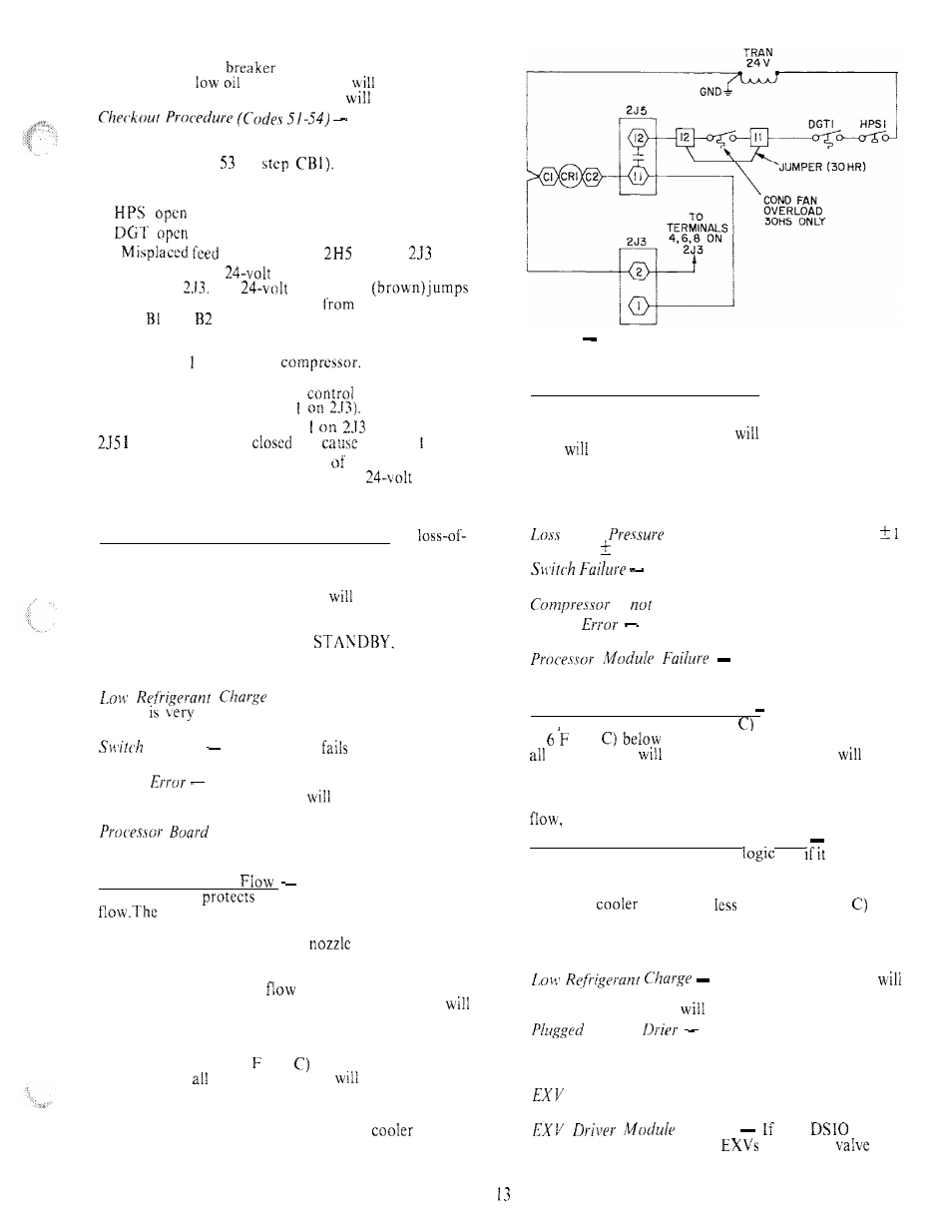

The processor closes the contacts between 255 ter-

minals 12 and I to start the

(See Fig. 3.) The

safeties shown to the right of 2.15 must be closed for

power to reach the compressor

relay (CR 1) and

the feedback input (terminal

Failure of power to terminal

when contacts

I and I2 should be

wilt

a code 5 alarm.

Terminal 2 on 293 is the other leg the compressor Al

feedback channel. It is connected to the

ground.

Code 59 and 60, Loss of Refrigerant Charge

A

charge switch is connected to the high-pressure side of

the refrigerant system. The microprocessor monitors this

switch directly; if it opens, all the compressors in the

circuit will be locked off, the alarm

be energized and

the display code will appear when the alarm display is

accessed. To reset, use the manual reset method (move

the RUN/STANDBY switch to

then back

to RUN).

Following are some possible causes for this alarm:

If the system refrigerant

charge

low, the microprocessor will detect this

through the switch and indicate the error.

Failure

If the switch

open, the micro-

processor will detect this and indicate an error.

Wiring

If there is a wiring error that causes an

open circuit, the microprocessor

treat this as an open

switch and indicate an error.

Failure

If the hardware in the pro-

cessor module fails in a manner that the switch cannot

be read properly, an error may be indicated.

Code 61, No Cooler

The microprocessor con-

tains logic that

the cooler against loss of cooler

cooler entering and leaving water temperature

sensors are used for this purpose. The leaving thermistor

is located in the leaving water

and the entering

sensor is located in the first cooler baffle space in close

proximity to the cooler tubes as shown in Fig. 4. When

there is no cooler water

and the compressors are

operating, the leaving water temperature thermistor

indicate no temperature change. But the temperature of

the entering water will drop rapidly and the entering

water thermistor will detect this. When the entering water

temperature drops to 5 (2.8

below the leaving water

temperature,

the compressors

stop and code

no. 61 will be displayed. To correct, use manual reset

method (after cooler water Row is resumed).

The error will be caused either by no

flow or

if the water is flowing in the wrong direction through the

cooler or if the thermistors have been interchanged.

Fig. 3

Compressor Al Control Wiring (Typical)

Code 63 and 64, Low Oil Pressure

A low oil pressure

switch is installed on the lead compressor in each circuit.

If the switch opens during operation of the compressor,

all the compressors

in

the circuit

be shut off, the alarm

light

be energized and the appropriate display code

shown. The switch will be bypassed for one minute during

start-up and for 45 seconds during normal operation. The

manual reset method must be used to reset this safety.

Possible causes for failure are:

of’

Oil

If the oil pressure is below 5

psig (34.5 6.9 kpa), the switch will open.

If the switch fails open, a failure will be

indicated.

is

running.

wiring

If a wiring error exists that causes an

open circuit, an error will occur.

If the hardware on the

processor module fails in a manner that the switch cannot

be read properly, an error may be indicated.

Code 65, Cooler Freeze Protection If the leaving water

temperature is below 35 F (1.7

for a water chiller or

is

(3.3

the set point for brine applications,

compressors

be stopped. This safety

auto-

matically reset when the water temperature is 6 F (3.3 C)

above the set point.

The causes for this failure are usually due to low cooler

or extremely rapid load changes.

Code 66 and 67, High Suction Superheat

The micro-

processor contains the following

and

is satisfied,

all the compressors in the circuit will be stopped:

Suction superheat is greater than 75 F (4f.7 C), and

saturated

suction is

than 55 F (12.8

and

these 2 conditions have been true for more than5 minutes.

To reset this, use the manual reset method.

Causes

for this failure are:

A low refrigerant charge

not allow the correct amount of refrigerant to be fed to

the evaporator, which

result in a high superheat.

F i l t e r

If the liquid line filter drier

becomes plugged, it can result in not enough refrigerant

being fed to the evaporator, which results in a high super-

heat failure.

Failure

If the EXV fails to open enough to feed

the proper amount of refrigerant, the error will occur.

Failure

the

module

hardware that controls the

fails, the

will

not move.