Carrier HS070-160 User Manual

Page 20

- M U F F L E R S

MUFFLERS

COMPRESSORS

COMPRESSORS

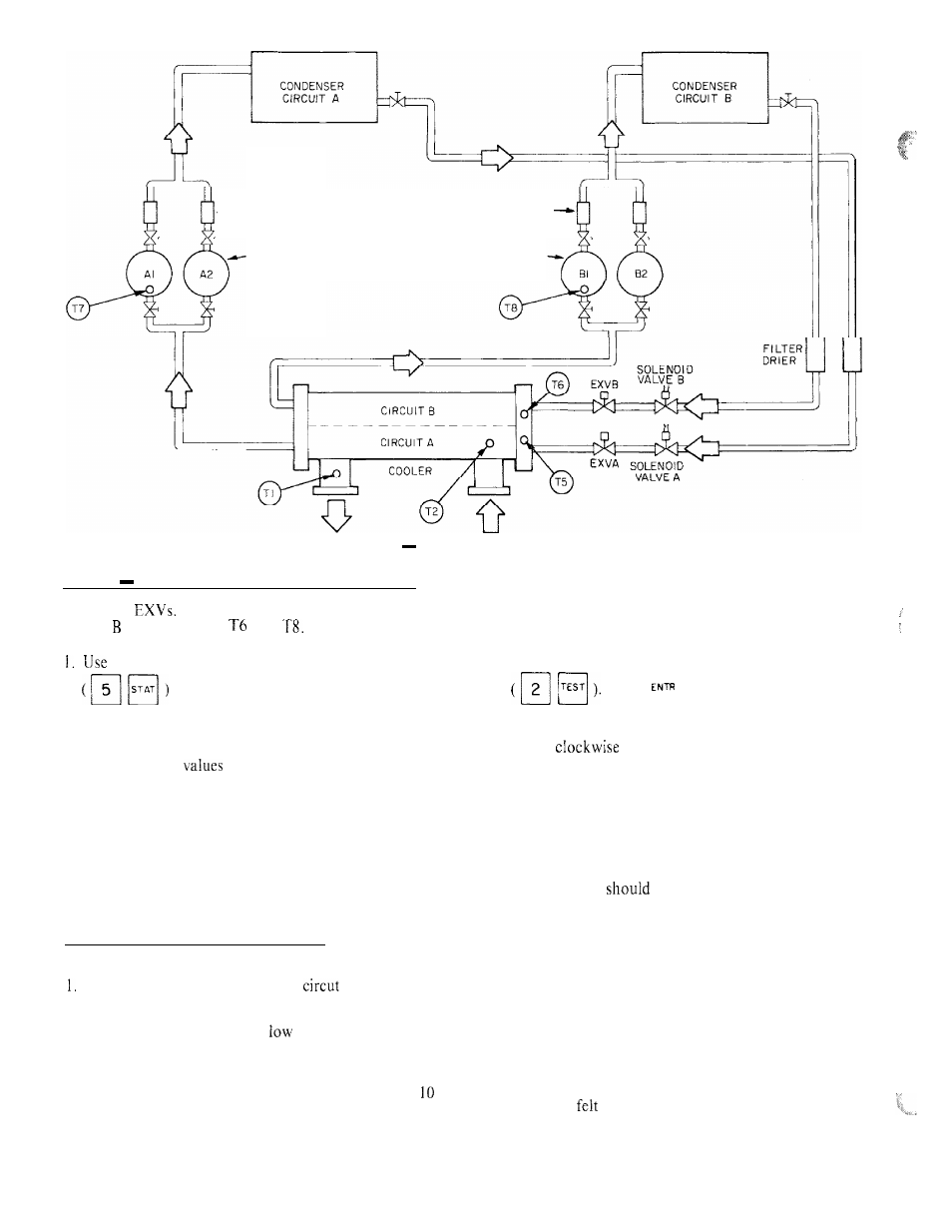

Fig. 9

Thermistor Locations

Step

4

Check Thermistors That Control EXV

Check thermistors that control processor output voltage

pulses to

Circuit A thermistors are T5 and T7.

Circuit thermistors are

and

Refer to Fig. 9 for

location.

the temperature subfunction of the status function

to determine if thermistors are reading

correctly.

2. Check thermistor calibration at known temperature

by measuring actual resistance and comparing value

measured with

listed in Table 8.

3. Make sure that thermistor leads are connected to

proper pin terminals at 157 terminal strip on processor

module and that thermistor probes are located in

proper position in refrigerant circuit (Fig. 9).

When above checks have been completed, actual

operation of EXV can be checked by using procedures

outlined in Step 5.

Step 5

Check Operation of the EXV

Use following

procedure to check actual operation ofelectronic expan-

sion valves.

Close liquid line service valve for

to be checked

and run through the Quick Test step (in subfunction

3 of test function) for the lead compressor in that

circuit to pump down the

side of the system.

Repeat test step 3 times to ensure that all refrigerant

has been pumped from low side.

NOTE: Be sure to allow compressors to run full

seconds at each step.

2. Turn OFF compressor circuit breaker(s). Close com-

pressor service valves and vent any remaining refrig-

erant from low side of system.

3. Remove screws holding top cover of EXV. Carefully

remove top cover, using caution to avoid damage to

the motor leads. If EXV plug was disconnected during

this process, reconnect it after the cover is removed.

4. Enter appropriate EXV Quick Test step for EVXA or

EXVB in the outputs subfunction of the test function

q

Press

to initiate test. With cover

lifted off the EXV valve body, observe operation of

valve motor and lead screw. The motor should turn

in the

direction and the lead screw should

move down into the motor hub until the valve is fully

closed or fully open depending on whether you initiate

the open or close test step for that valve. Lead screw

movement should be smooth and uniform from fully

open to fully closed position, or from fully closed to

fully open.

If valve is properly connected to processor and receiv-

ing correct signals, yet does not operate as described

above, the valve

be replaced.

The operation of the EXV valve can also be checked

without removing the top cover. This method depends on

the operator’s skill in determining whether or not the

valve is moving, To use this method, initiate the Quick

Test to open the valve. Immediately grasp the EXV valve

body with the hand. As the valve drives open, a soft,

smooth pulse will be felt for approximately 26 seconds

as the valve travels from fully closed to fully open. When

the valve reaches the end of its opening stroke, a hard

pulse will be felt momentarily. Drive the valve closed and

a soft, smooth pulse will be felt for the 26 seconds necessary

for the valve to travel from fully open to fully closed.

When the valve reaches the end of its stroke, a hard pulse

will again be

as the valve overdrives by 50 steps. The

valve should be driven through at least 2 complete cycles

to be sure it is operating properly. If a hard pulse is felt

for the 26 second duration, the valve is not moving and

should be replaced.

20