Carrier HS070-160 User Manual

Page 21

The EXV test can be repeated

by pressing

may be due to out-of-calibration

or inter-

mittent connections between processor board

a n d

plug. Recheck all wiring

voltage signals.

Other possible causes of improper

flow

control could be restrictions in liquid line. Check

plugged filter drier(s), stuck liquid line solenoid

or restricted metering slots in the EXV. Formation of ice

or frost on lower body of electronic expansion valve is

one symptom of restricted metering slots. Clean or

replace valve if necessary.

NOTE: Frosting of valve is normal during compressor

Quick Test steps and at initial start-up. Frost should

dissipate after 5 to minutes operation of a system that is

operating properly. If valve is to be replaced, wrap valve

with a wet cloth to prevent excessive heat from damaging

internal components.

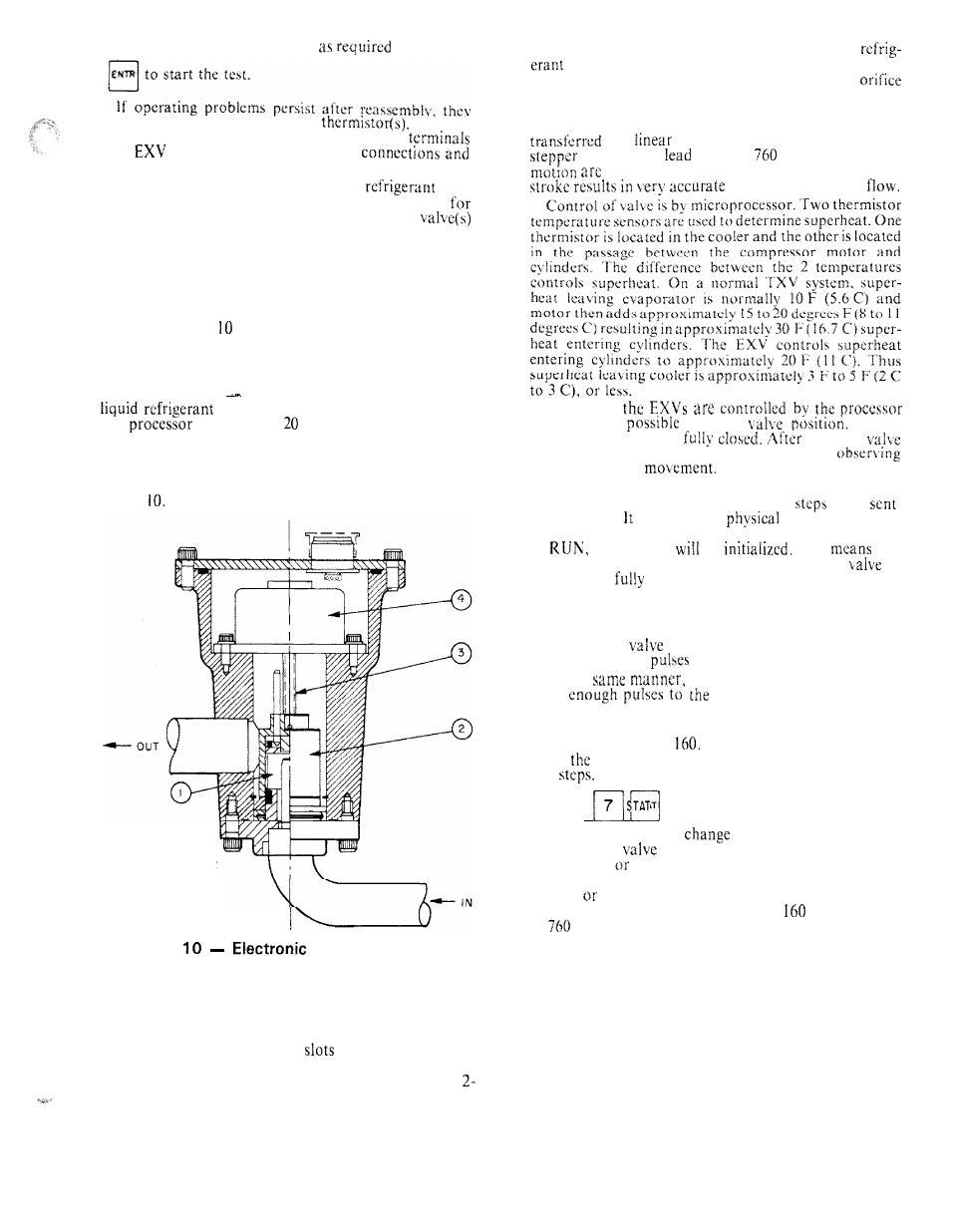

EXV OPERATION

These valves control the flow of

into the cooler. They are operated by

the

to maintain

degrees F of superheat

between the cooler entering refrigerant thermistor and the

lead compressor entering gas thermistor (located between

the compressor motor and the cylinders). There is one

EXV per circuit. A cutaway drawing of valve is shown

in Fig.

4 -STEPPER MOTOR

3 -LEAD SCREW

2 -PISTON

-ORIFICE ASSEMBLY

Fig.

Expansion Valve

High-pressure liquid refrigerant enters valve through

bottom. A series of calibrated

have been machined

in side of orifice assembly.

As

refrigerant passes through

orifice, pressure drops and refrigerant changes to a

phase condition (liquid and vapor). To control

flow for different operating conditions, piston

moves up and down over orifice, thereby changing

size. Piston is moved by a linear stepper motor. Stepper

motor moves in increments and is controlled directly by

processor module. As stepper motor rotates, motion is

into

movement by lead screw. Through

motor and

screws,

discrete steps of

obtained. The large number of steps and long

control of refrigerant

B e c a u s e

module, it is

to track

During

initial start-up, EXV is

start-up,

position is tracked by processor by constantly

amount of valve

The processor keeps track of the EXV position by

counting the number of open and closed

it has

to each valve. has no direct

feedback of valve

position. Whenever the unit is switched from STANDBY

to

both valves

be

This

the

processor will send enough closing pulses to the

to

move it from

open to fully closed and then reset the

position counter to zero.

The EXV open Quick Tests will send enough pulses to

the valve to drive it from fully closed to fully open. The

position of the

at the start of the test has no effect

on the number of

sent.

In the

the EXV close Quick Tests will

send

valve to drive it from fully

open to fully closed,

When the EXV opens, the metering slots are not

uncovered until step

This is fully closed position

when

circuit is operating. The fully open position is

760

T h e

subfunction shows the EXV valve

positions. They should

constantly while the unit

operates. If a

should stop moving for any reason

(mechanical

electrical) other than a processor or

thermistor failure. the processor will continue to attempt

to open close the valve to correct the superheat. Once

the calculated valve position reaches

(fully closed)

or

(fully open) it will remain there. If the EXV posi-

tion reading remains at 160 or 760 and the cooler and

compressor refrigerant thermistor displays are reading

the measured temperature correctly, the EXV is not

moving. Follow the EXV checkout procedure to deter-

mine the cause.

The EXV is also used to limit cooler suction tem-

perature to 55 F (13 C). This makes it possible for the

chiller to start at higher cooler water temperatures with-

out overloading compressor. This is commonly referred

to as MOP (maximum operating pressure).

21