Maintenance – AERCO BMK 3.0 LN Nat. Gas Jan 2011 User Manual

Page 54

MAINTENANCE

5. Next, lo osen an d r emove the i gnitor-injector

from the burner housing using a 1" open-end

wrench.

6. Check the ign itor-injector f or evide nce of

erosion or c arbon b uild-up. If ther e is

evidence of s ubstantial erosion or c arbon

build-up, the

ignitor-injector s hould b e

replaced. If carbon build-up is present, clean

the c omponent us ing f ine em ery c loth.

Repeated c arbon bui ld-up is an indic ation

that the c ombustion s ettings of the unit

should be c hecked. Ref er to Ch apter 4 f or

combustion calibration procedures.

7. Prior to reinstalling the ignitor-injector, a high

temperature, c onductive, ant i-seize c om-

pound must be applied to the threads.

NOTE

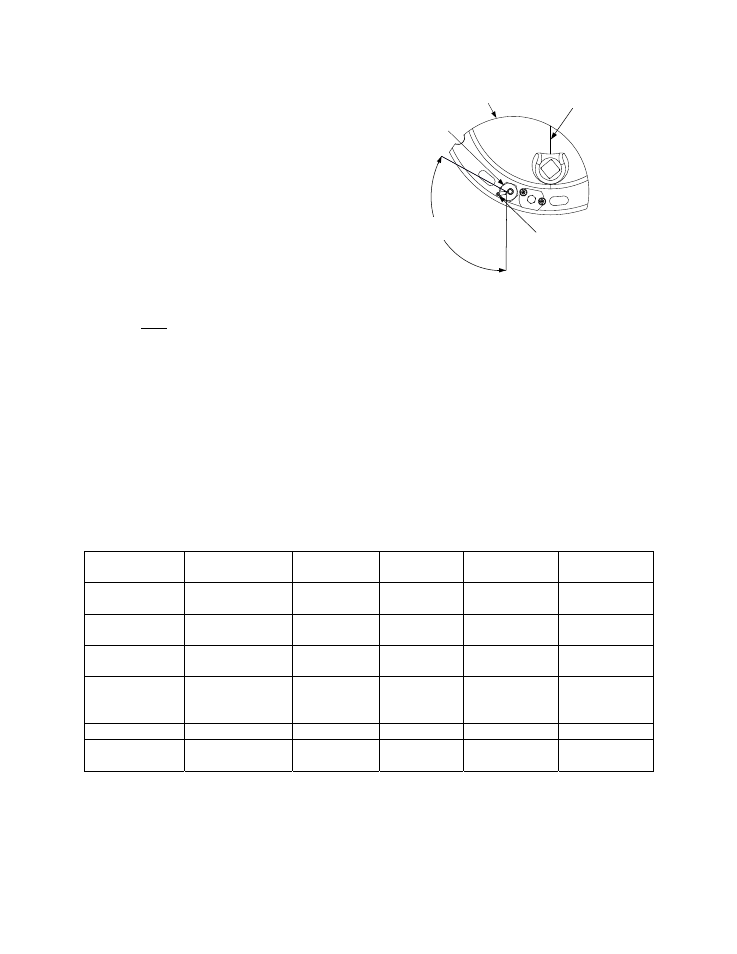

If a r eplacement ignitor -injector ( part no.

58023) is bei ng i nstalled, a c ompression

nut c ontaining a b uilt-in f errule wil l be

included with t he r eplacement par t. If

needed, 3 i ndexing washers ar e als o

included. These washers may be needed

to pr operly position the gas inj ector tube

of the ignitor-injector within the 120° angle

shown in Figure 7-2.

120

120

DEG.

GAS INJECTOR TUBE

MUST BE WITHIN

THIS RANGE

IGNITOR-

INJECTOR

BURNER

HOUSING

HOUSING

CENTERLINE

Fgurei 7-2

Burner Assembly – Top View

8. Reinstall the ignitor-injector in th e bur ner

housing and t orque t o 80 to 90 i

n-lbs.

However, if the burner housing was replaced

just pr ior to r eplacing t he ig nitor-injector,

torque to 1 80 in-lbs, then lo osen a nd r e-

tighten to 80 to 90 in-lbs.

9. Connect the s taged ig nition as sembly to t he

gas inj ector t ube of the ignitor-injector b y

securing the compression nut to t he elbow of

the staged ignition assembly.

10. Reconnect the ignitor-injector cable.

11. Reinstall the side and top panels on the unit.

Table 7-1 - Maintenance Schedule

PARAGRAPH

ITEM

6 Mos.

12 Mos.

24 Mos.

Labor

Time

7.2

Ignitor-Injector

(58023)

*Inspect

Inspect

Replace

15 mins.

7.3

Flame Detector

(66006)

*Inspect

Inspect

Replace

15 mins.

7.4

Combustion

Calibration

*Check

Check

1 hr.

7.5

Testing of

Safety Devices

See CSD-1

Chart in

Appendix I

20 mins.

7.6

Burner

Inspect

2 hrs.

7.7

Condensate

Drain Traps

*Inspect

Inspect &

Clean

1 hr.

* Only performed after initial 6 month period after initial startup.

7-2