Gf-123, Benchmark 2.0ln low nox boiler – AERCO BMK 2.0 LN October 2012 User Manual

Page 87

GF-123

Benchmark 2.0LN Low NOx Boiler

Chapter 7

OMM-0046_0F

I

nstallation, Operation and Maintenance Manual

Maintenance

PR1 10/17/12

AERCO International Inc.● 100 Oritani Dr. ● Blauvelt, NY 10913. ● Ph: 800-526-0288

Page 87 of 172

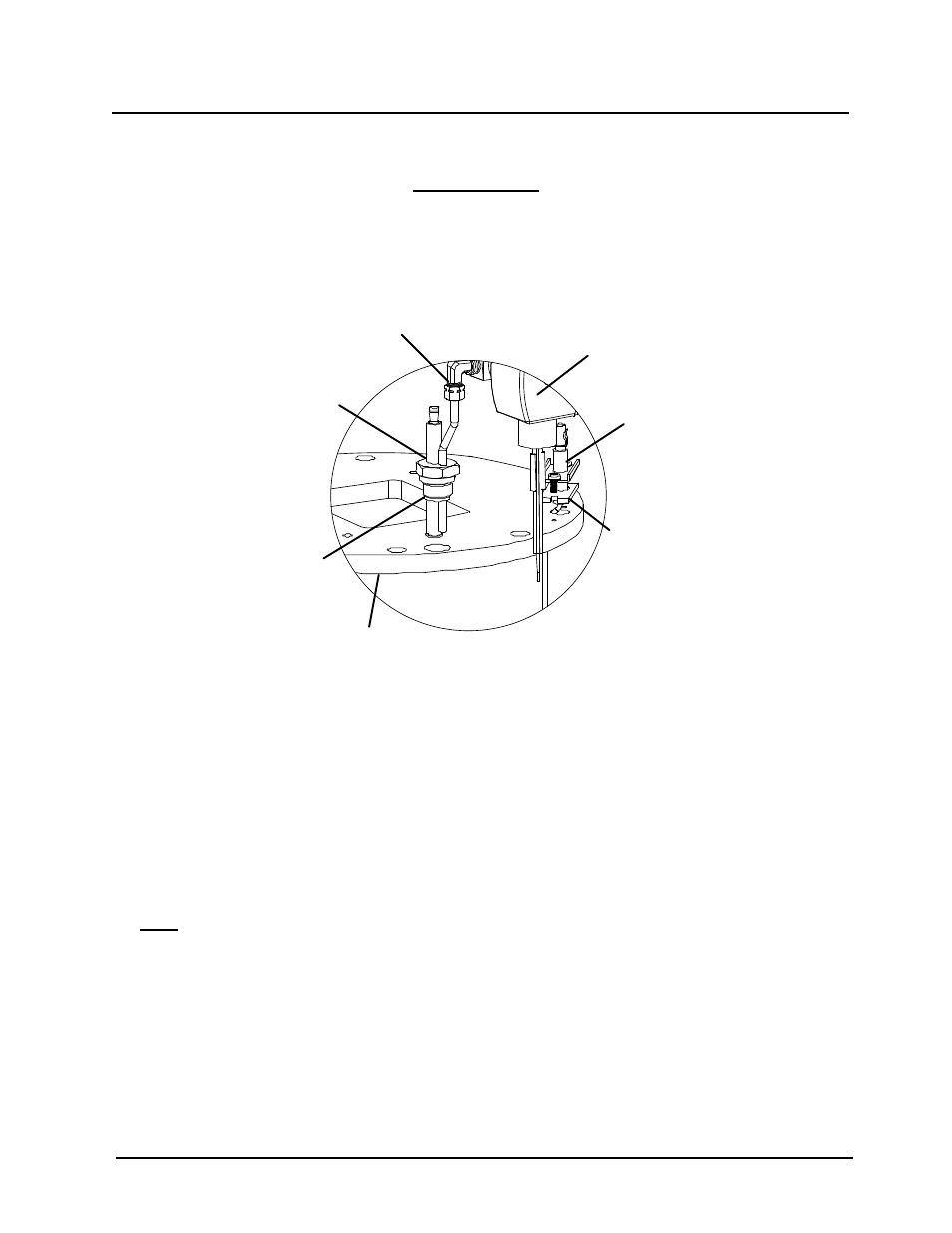

IMPORTANT

Prior to removing the igniter-injector, note the position of the gas injector

tube relative to the burner plate and blower. This is necessary to ensure

that the igniter injector is reinstalled in the proper orientation when it is

reconnected to the staged ignition assembly.

STAGED

IGNITION

ASSEMBLY

FLAME

DETECTOR

IGNITOR-

INJECTOR

BURNER

PLATE

COMPRESSION

FITTING & ELBOW

FLAME

DETECTOR

GASKET

INDEXING

WASHERS

(QTY = 0-3

AS REQ’D)

Figure 7-2: Igniter-Injector & Flame Detector Mounting Details

5. Next, loosen and remove the igniter-injector from the burner plate using a 1" open-end

wrench.

6. Check the igniter-injector for evidence of erosion or carbon build-up. If there is evidence of

substantial erosion or carbon build-up, the igniter-injector should be replaced. If carbon

build-up is present, clean the component using fine emery cloth. Repeated carbon build-up

is an indication that the combustion settings of the unit should be checked. Refer to Chapter

4 for combustion calibration procedures.

7. Prior to reinstalling the igniter-injector, a high temperature, conductive, anti-seize compound

must be applied to the threads.

NOTE

If a replacement igniter-injector (part no. 58023) is being installed, a

compression nut containing a built-in ferrule will be included with the

replacement part. If needed, three indexing washers are also included

These washers may be needed to properly position the gas injector tube of

the igniter-injector within the 120° angle range shown in Figure 7-3.