Benchmark 2.0ln low nox boiler, Gf-123 – AERCO BMK 2.0 LN October 2012 User Manual

Page 100

Chapter 8

Benchmark 2.0LN Low NOx Boiler

GF-123

Troubleshooting Installation, Operation and Maintenance Manual

OMM-0046_0F

Page 100 of 172 AERCO International Inc.● 100 Oritani Dr. ● Blauvelt, NY 10913. ● Ph: 800-526-0288

PR1 10/17/12

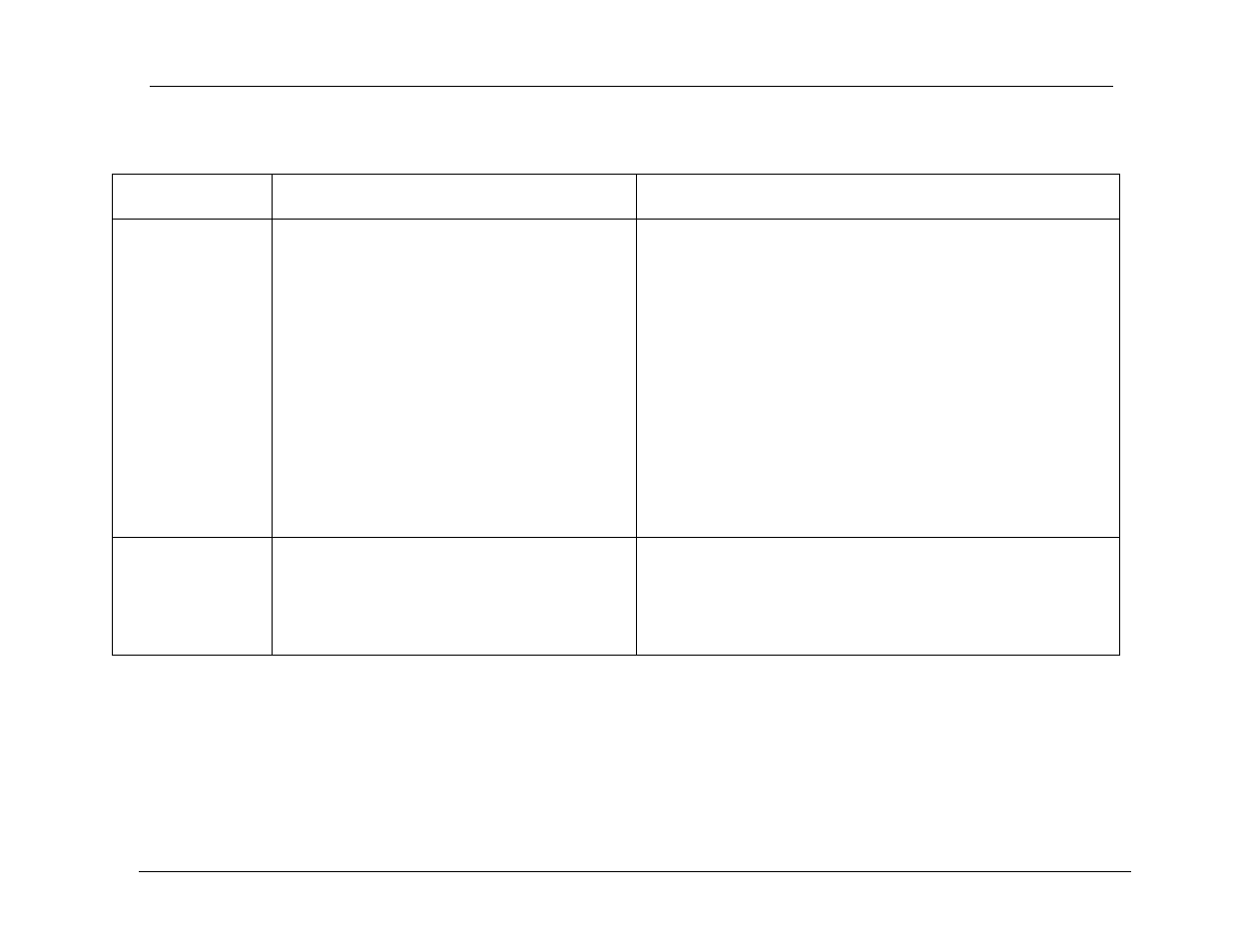

TABLE 8-1. BOILER TROUBLESHOOTING (Continued)

FAULT

INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

AIRFLOW FAULT

DURING RUN

1. Blower stopped running due to thermal or

current overload

2. Blocked Blower inlet or inlet ductwork

3. Blocked airflow switch

4. Defective airflow switch

5. Combustion oscillations

6. PROBABLE CAUSES from 3 to 16 for

AIRFLOW FAULT DURING IGNITION applies

for this fault

1. Check combustion blower for signs of excessive heat or high

current draw that may trip thermal or current overload devices.

2. Inspect the inlet to the combustion blower including any ductwork

leading up to the combustion blower for signs of blockage.

3. Remove the airflow switch and inspect for signs of blockage,

clean or replace as necessary.

4. Measure the airflow switch for continuity with the combustion

blower running. If there is an erratic resistance reading or the

resistance reading is greater than zero ohms, replace the switch.

5. Run unit to full fire. If the unit rumbles or runs rough, perform

combustion calibration.

6. See CORRECTIVE ACTIONS from 3 to 16 for AIRFLOW FAULT

DURING IGNITION.

DELAYED

INTERLOCK OPEN

1. Delayed Interlock Jumper not installed or

removed.

2. Device proving switch hooked to interlocks is

not closed

1. Check for a jumper properly installed across the delayed

interlock terminals in the I/O box.

2. If there are 2 external wires on these terminals, check to see if an

end switch for a device such as a pump, louver, etc. is tied these

interlocks. Ensure that the device and or its end switch are

functional. (jumper may be temporarily installed to test interlock)