Precautions for installation, 2 connection and installation, Installing the sj-m series – KEYENCE SJ-M300 User Manual

Page 6: Connection and installation, Freq

5

2-1

Before Installation

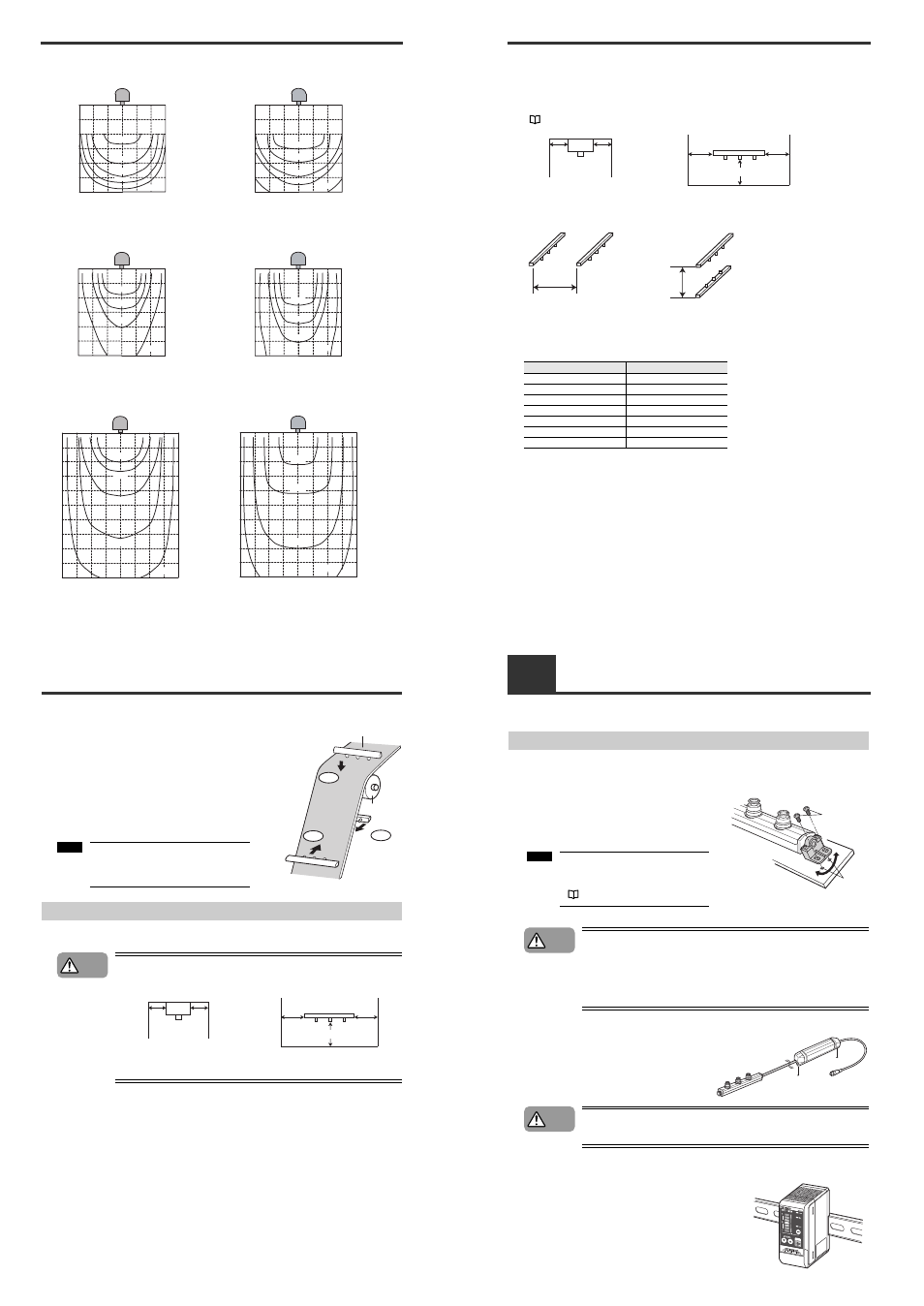

Model: SJ-M030V/030VC

At the time of frequency 50 Hz

Model: SJ-M070V/070VC

At the time of frequency 50 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge:

1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge:

1 NL/min (1 electrode)

At the time of frequency 8 Hz

At the time of frequency 8 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge:

1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge:

1 NL/min (1 electrode)

At the time of frequency 1 Hz

At the time of frequency 1 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge:

1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge:

1 NL/min (1 electrode)

50

100

150

50

100

150mm

50

100 150mm

0.4sec

0.6sec

1.0sec

1.5sec

2.0sec

50

100

150

50

100

150mm

50

100 150mm

0.4sec

0.6sec

1.0sec

1.5sec

2.0sec

150

300

450

300

600

900mm

150 300 450mm

10sec

15sec

30sec

5sec

150

300

450

300

600

900mm

150 300 450mm

10sec

15sec

30sec

5sec

300

450

600

150

450

300

150

600mm

300

600

900

1200

1500mm

20sec

30sec

10sec

6sec

4sec

300

450

600

150

450

300

150

600mm

300

600

900

1200

1500mm

20sec

30sec

10sec

4sec

2-1

Before Installation

■ Proper static elimination

To ensure proper static elimination, consider the following points.

If the target is in contact with metallic objects (grounding

conductor), the static charge of the target is not completely

eliminated.

Install the SJ-M Series in a location in which the target is not in

contact with any metallic objects (such as a grounding conductor).

If the film or sheet is an electrical insulator, only the static

electricity on the surface exposed to the static elimination bar

is eliminated.

To eliminate the static electricity on both surfaces, use another

SJ-M unit on the other side.

Precautions for installation

■ Locations

Refer to the following illustration to install the SJ-M Series.

• Provide enough space between the static elimination bar and surrounding

walls as shown in the figures below.

• When mounting the SJ-M Series, use the provided mounting bracket,

otherwise an accident or malfunction may result.

Target (film or sheet)

Metal roller

NG

OK

OK

• Install the static elimination bar in a

location that allow easy maintenance

access (to replace or clean parts).

Note

CAUTION

20mm

min.

20mm

min.

20mm min.

30mm

min.

30mm

min.

2-1

Before Installation

■ Interference

The Static Elimination Head may not function properly if there is a conductor (earthed body) located

nearby or if two or more units are used close to each other. In such an installation, refer to the figure

below and maintain the indicated distance between the conductor (earthed body). If a conductor (earthed

body) is located inside the distances indicated below, adjust using the ion balance manual setup.

"Ion Balance Adjustment Function" (page 7)

If two SJ-R units are used, refer to the following illustration and separate the static elimination bars

properly.

The interference distance between the conductive object and the static elimination bar and that

between the static elimination bars located in parallel are specified, on condition that the target is

located at the following distances under a down flow of 0.3 m/s.

The interference distance between the static elimination bars located face to face is specified under no

wind flow.

Frequency (Hz)

Operating distance (mm)

50

50

30

150

10

300

8

600

5

900

3

1200

1

1500

20mm

min.

20mm

min.

20mm min.

30mm

min.

30mm

min.

Side-to-side installation

300mm

min.

Face-to-face installation

100mm

min.

2-2

Connection and Installation

This section describes how to connect and install the Static Elimination Head and Controller Unit.

Installing the SJ-M Series

■ Installing the Static Elimination Bar

●

Install the static elimination bar in the desired location.

Adjust the angle of the mounting brackets so that the

static elimination bar is properly secured at the desired

angle. Tap M4 screw holes at the appropriate location

and secure the static elimination bar using M4 screws.

• Do not allow any objects to contact the static elimination bar after

installation, as this may lead to product breakdown.

• When installing the SJ-M Series, observe the minimum bending radius of all

provided cables. Also, do not install the SJ-M Series with the cables

deformed by staples or other objects. Doing so might cause the SJ-M Series

to malfunction.

●

When the mounting fixture is used:

When installing the drive unit, prepare tapped

mounting holes, and install the drive unit at a tightening

torque of 1 Nm or less (M4 screws: 1 Nm or less).

The M3 screws and bundling band for fastening the

mounting fixture must be prepared separately.

Make a space of 30 mm or more around the drive unit. Otherwise, the unit may

be damaged.

■ Installing the Controller unit

Mount the Controller Unit on the DIN rail.

M4 screws

M4 taps

In case of the side mounting, use the

ion balance adjustment function to

adjust the ion balance again.

(

page 7)

Note

CAUTION

M4 Tap

CAUTION

FREQ