Air purge function, I.c.c. setting – KEYENCE SJ-M300 User Manual

Page 10

9

3-4

Other Functions

By operation on the Controller Unit (operation/display section):

Hold down

simultaneously for about one

second to stop static elimination.

The three center LEDs of the ion monitor blink

(red).

Air Purge Function

Supplying clean air through the air duct on both ends of the static elimination bar will prevent the dust

accumulation on the electrode probes (SJ-M0

*

0G/V type). The air purge widens the static elimination

area and increases the speed of static elimination as well.

* The air pressure indicates the pneumatic value at the route of the joint.

Use clean air or dry air of temperature –25°C, and of mesh size of about 0.01 μm.

When supplying air to the SJSJ-G, SJ-V/VC Series, you can use the active carbon filter to decrease

the dust accumulation on the electrode probes.

• Be sure to limit the air pressure to 0.2 MPa. Exceeding this limit may cause

accidents or malfunction.

• Be sure to use clean air, dry air as the air for supplying to the Static

Elimination Head. Moisture or oil contained in the air or nitrogen may cause

discharge inside the Static Elimination Head, which may result in accidents

or malfunction.

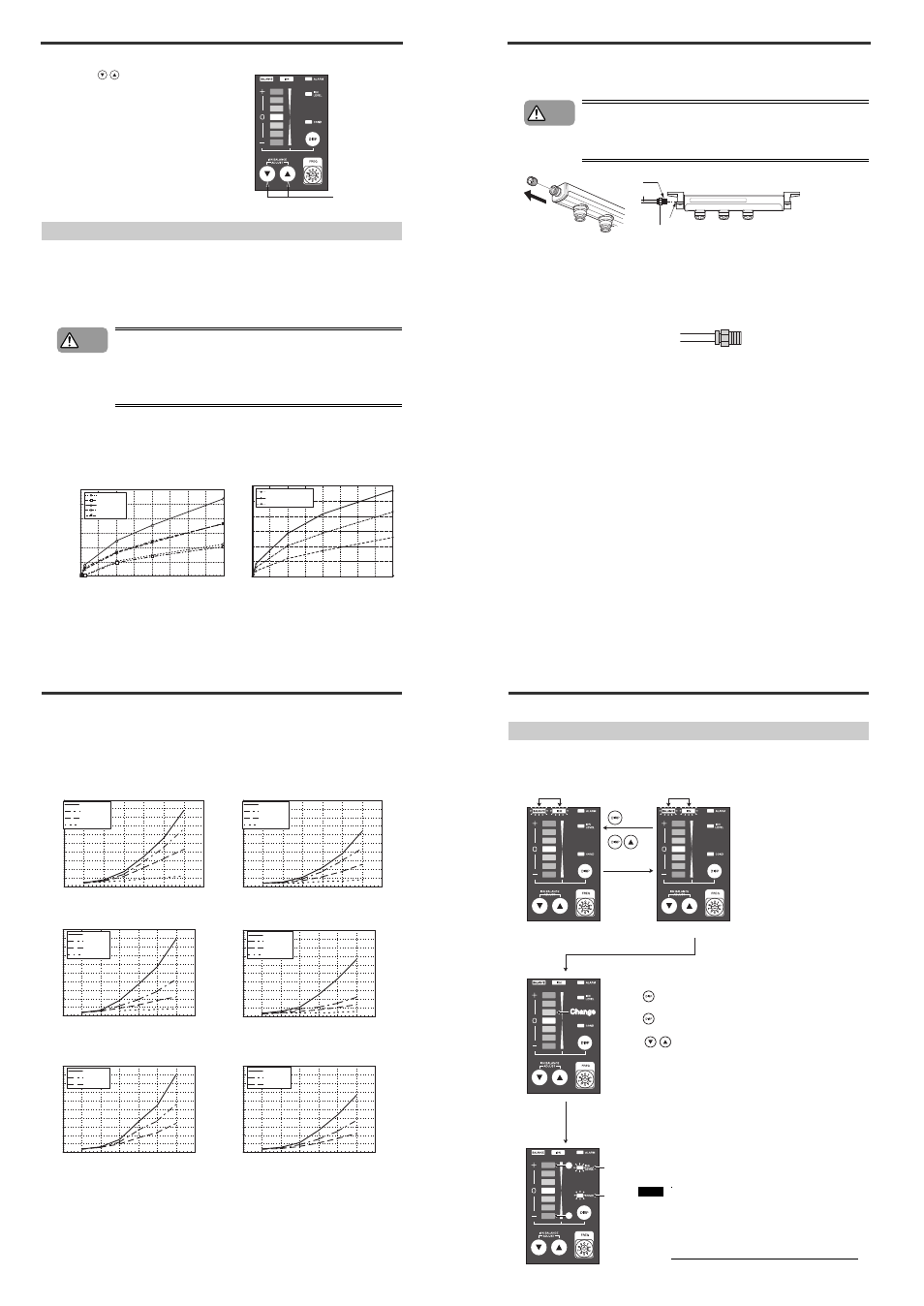

■ Relationship between air pressure and air flow with different bar lengths

The relationship between air pressure and air flow varies depending on the length of the static

elimination bar.

Refer to the typical example below to select the appropriate air supply device (compressor) that will

supply sufficient air flow.

Hold down for

at least 1 second.

CAUTION

50

60

40

30

20

10

0

0

0.05

0.1

0.15

0.2

Charged level (V)

Time (secs)

SJ-M030

SJ-M030C

SJ-M030G

SJ-M030V

SJ-M030VC

0.05

0.1

0.15

0.2

SJ-M070/070C

SJ-M070G

SJ-M070V/070VC

120

100

80

60

40

20

0

0

Air pressure(MPa)

Air flow(Nl/min)

3-4

Other Functions

■ Relationship between operating time and operating distance with different

air pressure

The relationship between operating time and operating distance varies depending on the air pressure.

Refer to the typical example on the right to select the appropriate air pressure.

Model: SJ-M030/030C

Model: SJ-M070/070C

Model: SJ-M030G

Model: SJ-M070G

* 9NL/min is minimum air flow to get a CAB effect.

* 21NL/min is minimum air flow to get a CAB effect.

Model: SJ-M030V/030VC

Model: SJ-M070V/070VC

* 3NL/min is minimum air flow to get a ACAB effect.

* 7NL/min is minimum air flow to get a ACAB effect.

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

No air

0.001MPa

0.01MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

No air

0.001MPa

0.01MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

No air

9NL/min

0.02MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

No air

21NL/min

0.02MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

3NL/min

0.05MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

200

250

300

350

Operating distance (mm)

Operating time (sec.)

7NL/min

0.05MPa

0.2MPa

3-4

Other Functions

■ Air supply method

As shown in the following figure, remove the screw which closes the air duct on the edge of the Static

Elimination Bar first. Then, attach a joint to the air duct and supply air.

• Be sure to limit the tightening torque to 2 N·m (20 kgf·cm) or less.

Otherwise, an accident or product breakdown may occur.

• Be sure to supply only clean, dry air. The use of improper air may cause an

accident or product breakdown.

●

Recommended joint

The recommended joint is the tube fitting(tube diamete:

I6 mm, I8 mm) manufactured by Pisco Co..

CAUTION

Tube

Rc1/8

Joint for end unit

R1/8

Tube diameter

I 6 mm : PC6-01SUS

Tube diameter

I 8 mm : PC8-01SUS

3-4

Other Functions

I.C.C. Setting

The I.C.C. (Ion Current Control) can be turned on and off.

Turning off the I.C.C. allows the ion balance adjustment function to generate positive and negative ions

at a fixed ratio.

Either of them lit

Blink alternately

Hold down

for at least

1 second

Hold down for at

least 1 second

simultaneously

Change

Blink

Blink

Change the 4th LED from the top in the Select mode.

Press for a short time

: advances to the Setup mode

of the selected item

Hold down for at least 1 second : exits the Select mode and

returns to the Run mode

: moves the cursor up and

down

On the ion monitor, the currently selected items are lit in green and the

items whose default have been changed are lit in red.

I.C.C. is set at ON by default setting.

Items that satisfy both of these conditions blink in red and green

alternately.

Advance to the I.C.C. ON/OFF setting from the Select mode in page 7,

and select either of the followings.

(1) I.C.C. ON (green) (Default)

(2) I.C.C. OFF (red)

When the I.C.C. OFF is selected, the ion level

alarm will not be output correctly. Ion level

monitor indication is not available, either. In the

Run mode, only the charge monitor is operating,

and the ion balance indicator and ion level

indicator light.

Important