Cub Cadet Medium Frame 3 Stage User Manual

Page 32

Medium Frame 2 & 3 Stage Snow Throwers

28

10.

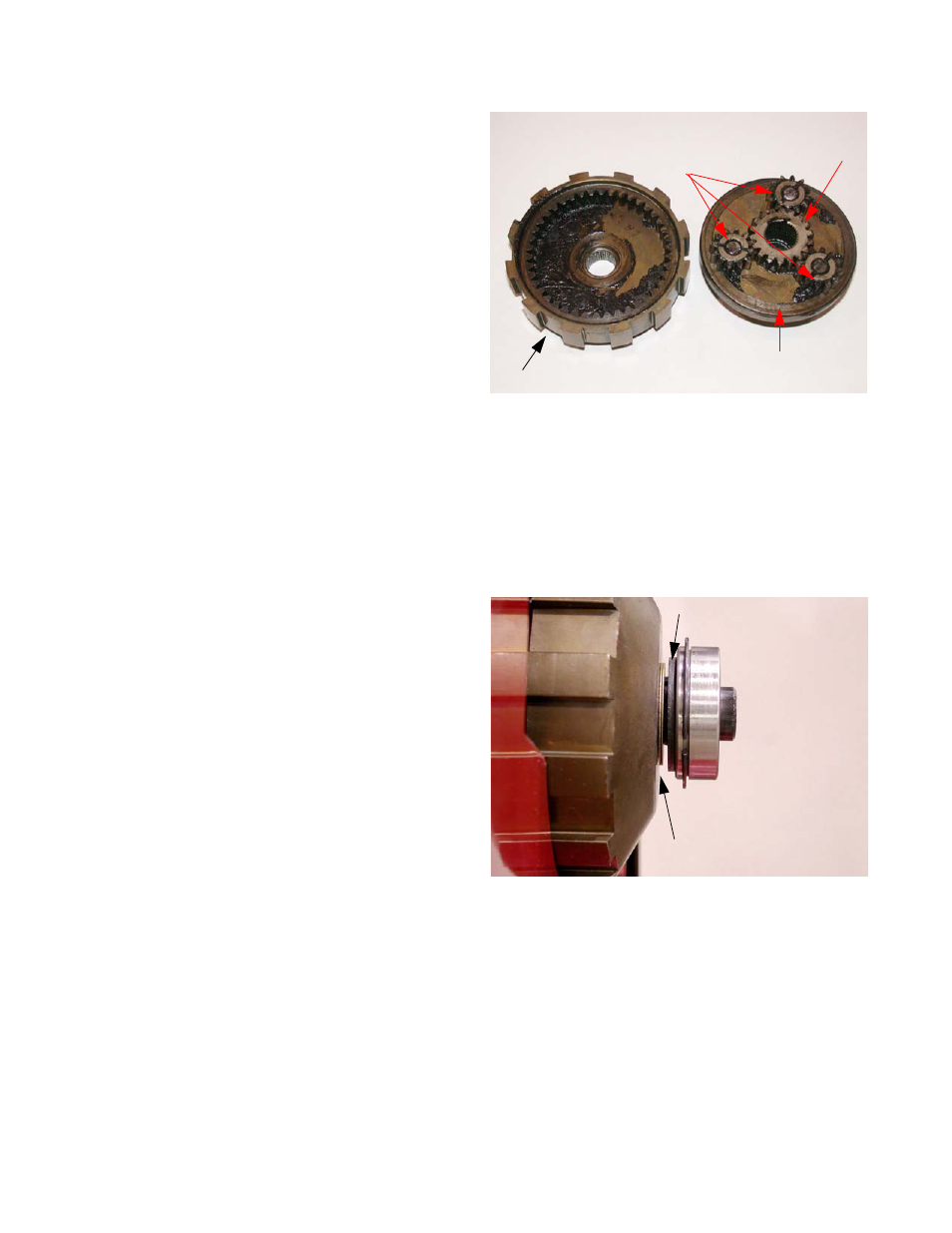

Inside of each planetary gear set is a series of plan-

etary gears that rotate around a sun gear and rotate

inside of the ring gear. See Figure 3.13.

NOTE: The groves are grease grooves.

11.

Although the planetary gears rarely have any ser-

vice issues, a good working knowledge is important.

•

The hex shaft transfers torque from the rubber

drive disc to the sun gear on each end of the

hex drive shaft.

•

The sun gear drives the planetary gears.

•

When unlatched (trigger squeezed) the ring

gear is allowed to spin freely.

•

When the ring gear spins freely it will not drive

the planetary gear carrier.

•

When the trigger is released and the ring gear

is latched (prevented from rotating). The planet

gears drive the carrier in the opposite direction

of the sun gear, but at greater speed.

•

The drive gear attached to the carrier transfers

power each side of the split axle.

NOTE: Examine all the gears: If one or more of the

gears failed because of something other

than normal wear, identify and correct the

cause before returning the snow thrower to

service.

NOTE: Starting with the 2013 production year, the

needle bearings in the ring gear, were

replaced with ball bearings. Seals were also

added.

12.

Install the gears by following the previous steps in

reverse order

13.

Apply a generous coating of Arctic Grease (737-

0318-CRTG) to the inside of the ring and planetary

gears.

NOTE: When installing the bearing, remember that

the wide side faces outward. See Figure 3.14.

14.

Repeat on opposite side.

15.

Test drive the snow thrower in a safe area before returning it to service.

Figure 3.13

Ring Gear

Sun Gear

Planetary gears

Planetary gear carrier

Figure 3.14

Washer/spacer

Shims