Checkline ESM301 User Manual

Page 4

Model ESM301 / ESM301L Version 2 Test Stand

User’s Guide

4

2 MECHANICAL SETUP AND SAFETY

2.1 Safety / Proper Usage

Typical materials able to be tested by the ESM301 include many manufactured items, such as springs,

electronic components, fasteners, caps, films, mechanical assemblies, and many others. Items that

should not be used with the ESM301 include potentially flammable substances or products, items that

can shatter in an unsafe manner, and any other components that can present an exceedingly hazardous

situation when acted upon by a force.

1. Using Grips & Fixtures with the ESM301

Ensure that the grip or fixture is positioned to ensure axial load with respect to the loading shaft of

the force gauge.

When using a grip, ensure that it secures the sample in such a way that it is

prevented from slipping out during a test, preventing a potential safety risk to the operator and

others in the vicinity. If using a grip or fixture from a supplier other than Mark-10, ensure that it is

constructed of suitably rugged materials and components.

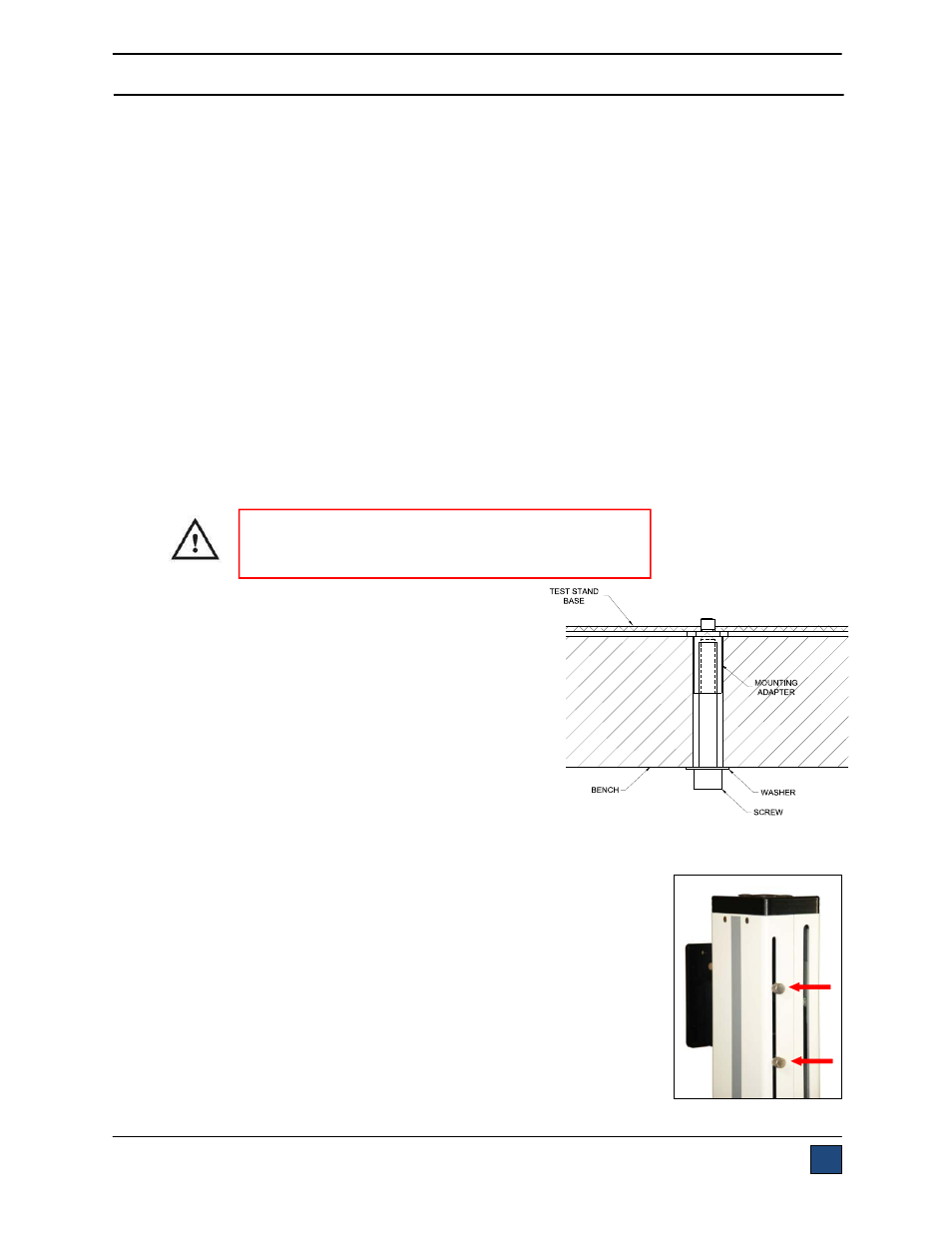

2. Mounting

Place the stand on a clean, flat and level work area free from vibration. If desired, the stand can

be secured to the work area with 1/4-20 screws fastened into the underside of the base. Failure

to properly mount the test stand may make it more vulnerable to tipping, causing a hazardous

situation.

The test stand can also be mounted using the

ESM301-003 mounting kit. Screws of various

lengths are supplied with this kit to accommodate a

range of bench thicknesses. Refer to the following

illustration at right proper assembly:

In general, the ESM301 can be mounted at any angle, although extra care should be taken during

installation and operation.

Once the test stand is in a stable and secure position, install a force

gauge with four thumb screws (provided). Mark-10 gauges mount

directly without adapters. Grips can be mounted onto the force gauge

and test stand base.

3. Installing the limit switches

Upper and lower limit switches are provided to stop crosshead travel at

user-designated positions. Each limit switch consists of an internal

block riding along a rail, and an external thumbscrew. The

thumbscrews are shipped in a separate bag to avoid damage in transit.

Refer to the illustration at right for proper installation:

IMPORTANT: Do not fasten any screws more than

0.25 in [6 mm] into the base of the test stand, or

damage to internal components can occur.