Checkline ESM301 User Manual

Page 25

Model ESM301 / ESM301L Version 2 Test Stand

User’s Guide

25

To clear any of the above errors, press STOP. The amber light in the STOP button will be blinking

when the error message is displayed.

2. The crosshead will move only in one direction, or not at all.

Possible causes:

1. Ensure all cables are plugged in properly, as described in Section 2.2.

2. Ensure that the force value has not exceeded the overload limits configured in the gauge.

3. Ensure that force gauge set points have been configured properly. Refer to Section 5.6 for

details.

3. The travel display value does not change when the crosshead moves.

Check to make sure the encoder cable is plugged in properly.

4. Certain menu items are no longer displayed.

All test stand functions are temporarily enabled for 160 hours of operation in Demo Mode. When

demo mode has expired, any functions (and their associated menu items) not originally

purchased will no longer be available.

9 MAINTENANCE AND SERVICE

The ESM301 should be operated in a dry and clean area. Under these circumstances only a few periodic

maintenance operations are required:

9.1 Acme screw lubrication – twice per year

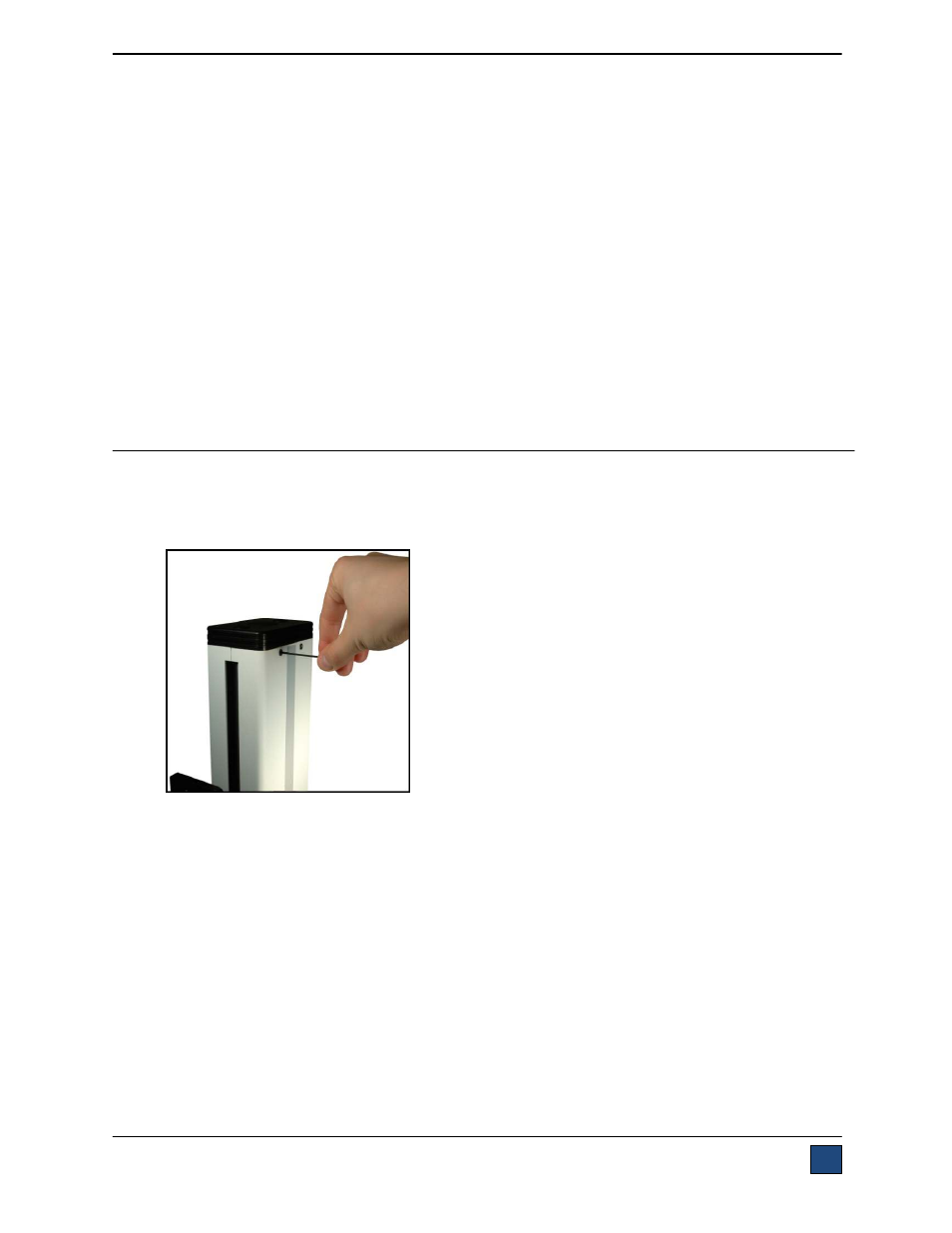

1. Remove the right column cover by loosening the screws, as shown above.

2. Using a brush, apply a small amount of silicon-based grease to the lead screw.

3. Cycle the crosshead up and down several times until the newly applied grease has been spread

evenly over the length of the screw. Re-install the column cover.

9.2 Check for loosened grips and attachments - daily

Check to ensure that the grips attached to the force gauge and base plate are firmly secured. Looseness

could result in a potentially hazardous situation.

Check for loosened components – once per month

1. Remove the test sample from the test stand.

2. Turn off power to the test stand and disconnect the power cord. Attempt to loosen