Brookfield CAP2000 Viscometer User Manual

Page 23

Brookfield Engineering Labs., Inc.

Page 23

Manual No. M02-313-G0812

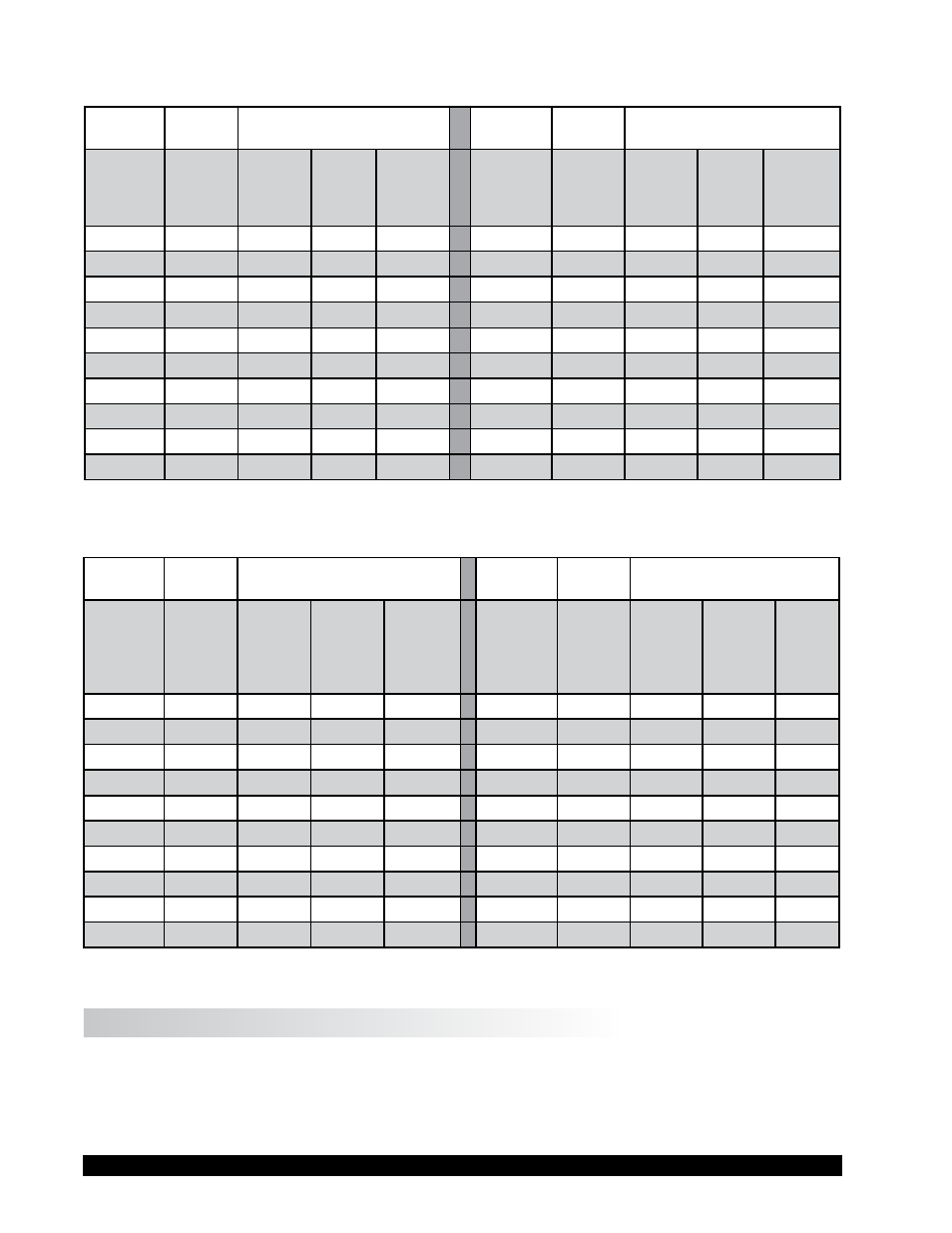

Table III-5: Viscosity Standard Fluids for Calibration of CAP Spindles on LOW TORQUE CAP 2000+ Viscometer

LOW

TORQUE

LOW

TEMP

LOW

TORQUE

HIGH

TEMP

Cone

Fluid

Part

Num-

ber

Nomi-

nal

Value

(cP)

Temp

(°C)

Sample

Size

(micro

liters)

Cone

Fluid

Part

Num-

ber

Nomi-

nal

Value

(cP)

Temp

(°C)

Sample

Size

(micro

liters)

CAP-S-01 CAP0L

57

25

67

CAP-S-01 CAP0H

57

60

67

CAP-S-02 CAP1L

89

25

38

CAP-S-02 CAP1H

89

60

38

CAP-S-03 CAP2L

177

25

24

CAP-S-03 CAP2H

177

60

24

CAP-S-04 CAP3L

354

25

124

CAP-S-04 CAP3H

354

60

124

CAP-S-05 CAP4L

708

25

67

CAP-S-05 CAP4H

708

60

67

CAP-S-06 CAP5L

1417

25

32

CAP-S-06 CAP5H

1417

60

32

CAP-S-07 CAP1L

89

25

1700

CAP-S-07 CAP1H

89

60

1700

CAP-S-08 CAP3L

354

25

400

CAP-S-08 CAP3H

354

60

400

CAP-S-09 CAP5L

1417

25

100

CAP-S-09 CAP5H

1417

60

100

CAP-S-10 CAP2L

177

25

170

CAP-S-10 CAP2H

177

60

170

Table III-6: Viscosity Standard Fluids for Calibration of CAP Spindles on HIGH TORQUE CAP 2000+ Viscometer

HIGH

TORQUE

LOW

TEMP

HIGH

TORQUE

HIGH

TEMP

Cone

Fluid

Part

Num-

ber

Nomi-

nal

Value

(cP)

Temp

(°C)

Sample

Size

(micro

liters)

Cone

Fluid

Part

Num-

ber

Nomi-

nal

Value

(cP)

Temp

(°C)

Sam-

ple

Size

(micro

liters)

CAP-S-01 CAP1L

89

25

67

CAP-S-01 CAP1H

89

60

67

CAP-S-02 CAP2L

177

25

38

CAP-S-02 CAP2H

177

60

38

CAP-S-03 CAP3L

354

25

24

CAP-S-03 CAP3H

354

60

24

CAP-S-04 CAP4L

708

25

124

CAP-S-04 CAP4H

708

60

124

CAP-S-05 CAP5L

1,417

25

67

CAP-S-05 CAP5H

1,417

60

67

CAP-S-06 CAP6L

3,542

25

32

CAP-S-06 CAP6H

3,542

60

32

CAP-S-07 CAP7L

1,328

25

1700

CAP-S-07 CAP7H

1,328

60

1700

CAP-S-08 CAP8L

5,313

25

400

CAP-S-08 CAP8H

5,313

60

400

CAP-S-09 CAP9L

21,250

25

100

CAP-S-09 CAP9H

21,250

60

100

CAP-S-10 CAP10L

236

25

170

CAP-S-10 CAP10H

236

60

170

III.4 Cone Calibration

A special feature of the CAP Series Viscometers allows the user to perform a cone calibration

using Viscosity Standard Fluids. This field calibration will accommodate any wear on the tip

of the cone which may result from contact with the plate. This also allows the user to purchase

a new cone spindle and perform the calibration in your plant.