Ii. getting started – Brookfield CAP2000 Viscometer User Manual

Page 12

Brookfield Engineering Labs., Inc.

Page 12

Manual No. M02-313-G0812

II. GETTING STARTED

II.1 Power On

Turn the power ON using the switch located on the rear of the base console.

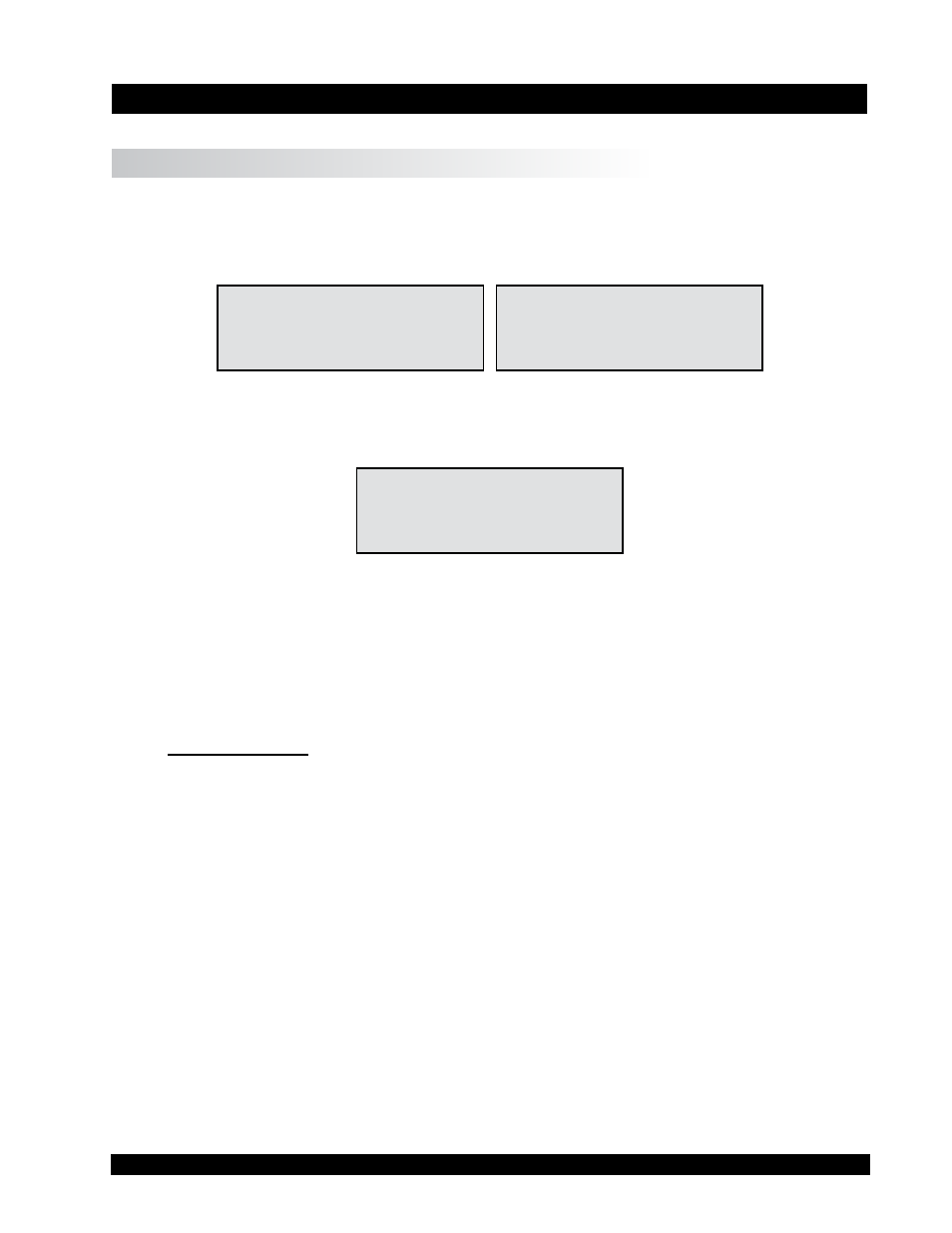

The start-up screen will be displayed for four seconds and will indicate the viscometer model,

version number and torque range.

BROOKFIELD

CAP 2000+ VISCOMETER

VERSION 1.10

1.0 CAP

BROOKFIELD

CAP 2000+ VISCOMETER

VERSION 1.10

22.7 CAP

Figure II-1A

Figure II-1B

Start-up Screen for High Torque CAP

Start-up Screen for Low Torque CAP

After four (4) seconds, the main screen will be displayed (Figure II-2).

0.00P

0.0%

Run 15

Spindle 04

50.0C

900 RPM

Figure II-2

The instrument will be set to the default temperature:

CAP L Series Viscometer

25.0°C

CAP H Series Viscometer

50.0°C

If the CAP 2000+ Viscometer is connected to a PC via the serial port on the rear of the base

console, the main screen display is EXTERNAL.

Special Functions

Units of measure and speed control may be selected through the special functions screen. This

screen is accessed by pressing the STOP key during instrument power up.

The CAP 2000+ can be configured to control speed by either rotations per minute (RPM) or

shear rate (1/SEC). This selection is set by choosing 1=SPEED CONTROL in the special func-

tions screen, then selecting 1=RPM or 2=1/SEC and pressing ENTER.

The CAP 2000+ can be configured to display viscosity in one of four units: Poise (P), Centipoise

(cP), Pascal Seconds (Pa•s) or milliPascal seconds (mPa•s). This selection is set by choos-

ing

2=Units of Measure

in the special functions screen, selecting

1=P

,

2=cP

,

3=Pa•s

,

or

4=mPa•s

, and then pressing ENTER.

Once the CAP 2000+ has been configured, the instrument must be turned OFF. The configura-

tion will be stored in memory.

Note: When operating the CAP 2000+ with shear rate as the method of speed control,

the shear rate value entered may be adjusted based on the shear rate multiplier

for the spindle. For example: if using cone 4 (shear rate multiplier of 3.33), an

entered shear rate of 51 1/SEC will be displayed as 50 1/SEC.