Iii. operation – Brookfield CAP2000 Viscometer User Manual

Page 18

Brookfield Engineering Labs., Inc.

Page 18

Manual No. M02-313-G0812

III. OPERATION

The CAP 2000+ Viscometer rotates a precisely machined cone spindle over a temperature

controlled plate shearing the test sample over a range of speeds from 5 to 1000 RPM. This

provides a comprehensive capability to analyze materials for viscosity behavior as a function

of both shear rate and temperature. Tests can be run in standalone mode or under PC control.

This chapter explains how to use the CAP 2000+ toward these objectives.

III.1 Full Scale Range and Accuracy of Measurement

Full Scale Range (FSR) viscosity is the maximum viscosity that can be measured and occurs

when the % torque is 100. Brookfield recommends that viscosity measurements be made be-

tween 10 and 100% torque.

There are two tables to consult for viscosity range information, depending on which torque

model viscometer you purchased. To determine which torque model you have, consult the se-

rial tag of your viscometer or the certificate of calibration that accompanied the instrument or

the display on power up.

23CAP 2000+ = Low Torque

CAP 2000+ = High Torque

Full Scale Range (FSR) is based on the cone spindle your are using, the torque model of your

viscometer, and the speed of spindle rotation. The tables below provide information on FSR

by torque model for the most common factory set speeds:

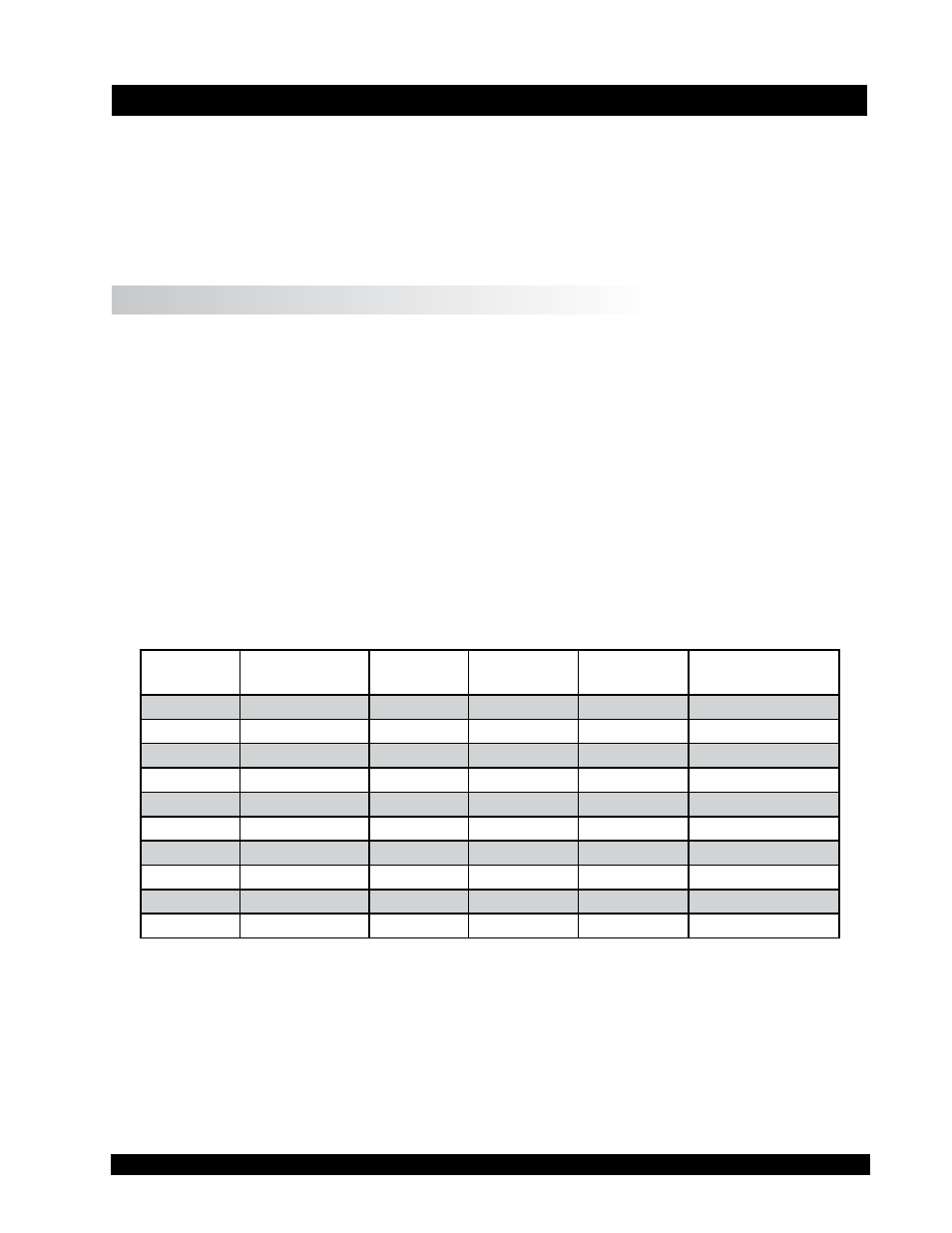

Table III-1: Full Scale Range Viscosity for LOW TORQUE CAP 2000+ Viscometer

Cone

Number

Cone Constant

Range

Shear Rate

Constant

FSR Poise at

100 RPM

FSR Poise at

500 RPM

FSR Poise at

any RPM

01

1875

13.33N

0.83

0.17

1875/(22.7*N)

02

3750

13.33N

1.65

0.33

3750/(22.7*N)

03

7500

13.33N

3.30

0.66

7500/(22.7*N)

04

15000

3.33N

6.61

1.32

15000/(22.7*N)

05

30000

3.33N

13.22

2.64

30000/(22.7*N)

06

75000

3.33N

13.04

6.61

75000/(22.7*N)

07

3150

2N

1.39

0.28

3150/(22.7*N)

08

12500

2N

5.51

1.10

12500/(22.7*N)

09

50000

2N

22.03

4.41

50000/(22.7*N)

10

5000

5N

2.20

0.44

5000/(22.7*N)

N

= RPM

Poise x 100 = centiPoise