Brookfield CAP2000 Viscometer User Manual

Page 16

Brookfield Engineering Labs., Inc.

Page 16

Manual No. M02-313-G0812

Note: With a run time of zero, the hold time will not be used

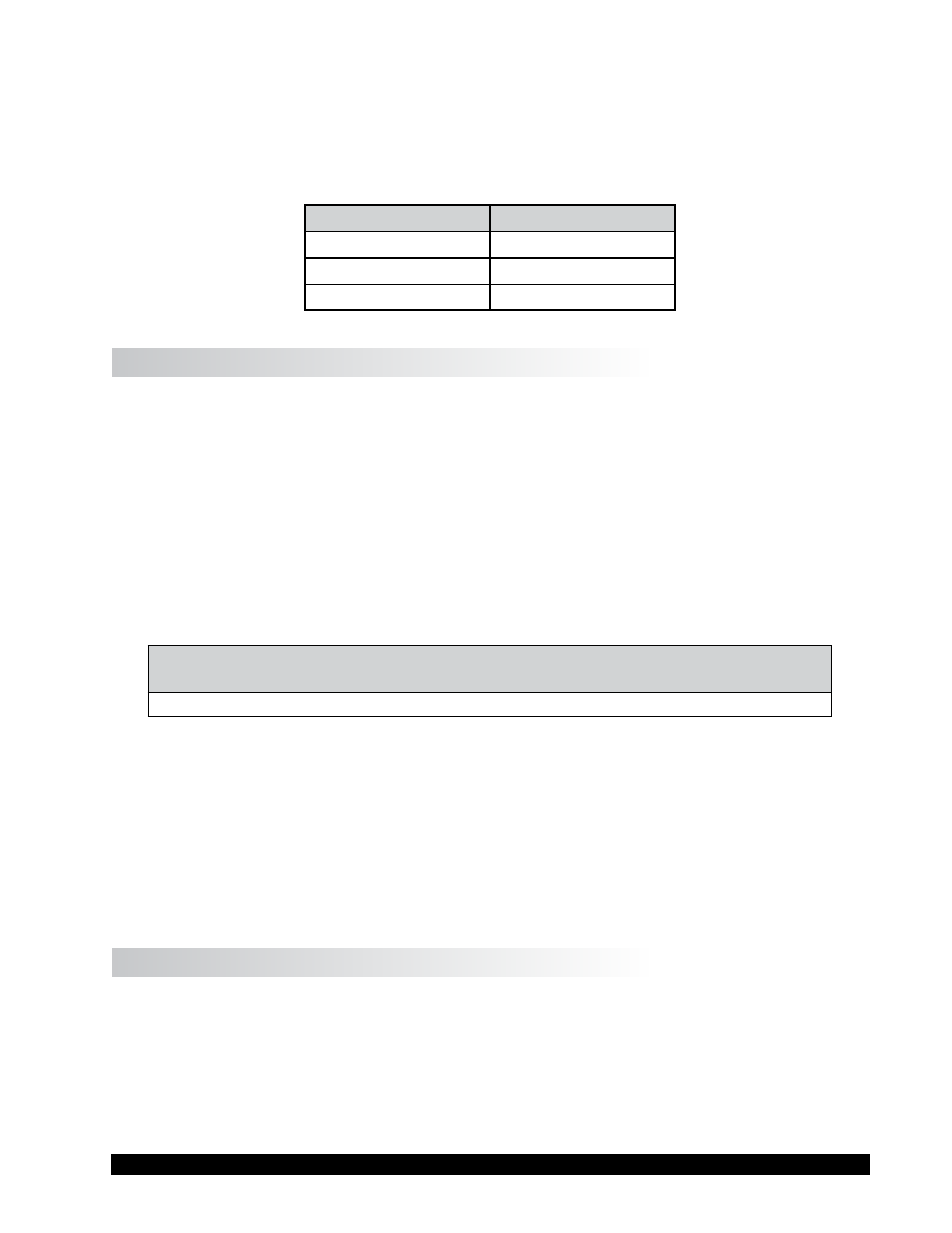

The time required for reading stabilization will depend on the speed of rotation and the nature

of the test sample. Longer runs times are recommended at lower speeds.

Speed

Run

50-1000 RPM

12 seconds

20-50 RPM

20 seconds

5-20 RPM

30 seconds

II.7 Printing

Pressing the PRINT key at any time sends information on test parameters to the printer port.

Note: Calculated parameters (Viscosity, Full Scale Range, Shear Stress) will be displayed

only after the spindle has rotated sufficiently to allow for accurate data. If print is

pressed before these parameters are displayed, then no data will be included in the

print string.

To print a heading, press and hold the STOP/ESCAPE key and press the PRINT key. Then start

the test by pressing the RUN key. Press the PRINT key whenever data is desired during the test.

Example of CAP 2000+ PRINT OUTPUT showing heading and data.

VISCOSITY

(POISE)

F.S.R.

(%)

TEMP

(Deg C)

S.STRESS

(D/CM2)

S.RATE

(1/sec)

SPEED

(RPM)

TIMER

(SEC)

CONE

No.

-

-

25.0

-

10000

0750

20

02

Figure II-5

A maximum value of 999 seconds can be printed in the time column when running in manual

TIMER mode (00). Over 999 seconds will print EEEE.

The TIMER (SEC) column will indicate the accumulated time of running at the moment the

print key is pressed while the cone is rotating. This time value will not include the hold time.

At the end of a test, data will automatically be sent to the printer port.

II.8 Run and Stop Keys

The

RUN

key has three functions:

1. Press RUN to begin a test.

2. Press and hold the RUN key for continuous rotation when 00 is the run time setting.

3. Used in executing a cone calibration.

The

STOP

key has three functions:

1. Stops the cone rotation at any time.