Satellite Slide Tank User Manual

Page 29

service. This is important because the

cleaning procedure will rid the pump of

both dirt and the necessary oil for

lubrication.

Check vane wear at the interval

recommended in your OEM pump manual.

It is important to stay on top of vane wear

because most pump manufacturers do not

warrantee damage caused by vane

breakage.

Table 4.4 High Vane Wear Operating Conditions

The conditions below will reduce vane life and

necessitate more frequent vane wear checking

Fine grit in intake air (e.g. sand, rust, or soil dust

particles)

Many long intervals in operation*

Many intervals of high Hg. operation* (e.g. as when

required to lift product a great distance).

Consistent use of pressure dumping

Running the pump dry on oil

Using the wrong oil in pump (use only manufacturer

recommended oil in your pump)

Any situation in which the pump overheats

Lack of periodic pump flushing maintenance

Lack of pump flushing maintenance after water has

entered the pump

Attempting to engage a pump that is frozen with

ice(before thawing the pump out)

You may need to change your vanes more

often than the manufacturer’s

recommendation if your pump is subjected

to very heavy use. See table 4.4 for

examples of heavy use factors that can

shorten vane life.

When vane wear exceeds ¼” (for most

pumps), the vanes must be replaced. New

vanes, when bottomed in the rotor slots,

will be flush with the outside diameter of

the rotor. As such, vane wear is

determined by measuring how deep the

edge of the worn vane sits below the

outside of the rotor.

In addition, if the pump volume declines

significantly (i.e. it takes longer and longer

to fill the tank), then the vanes probably

need to be changed.

*Note: Pumps rated for continuous or heavy duty

operation (such as liquid cooled pumps) can handle

these conditions more readily.

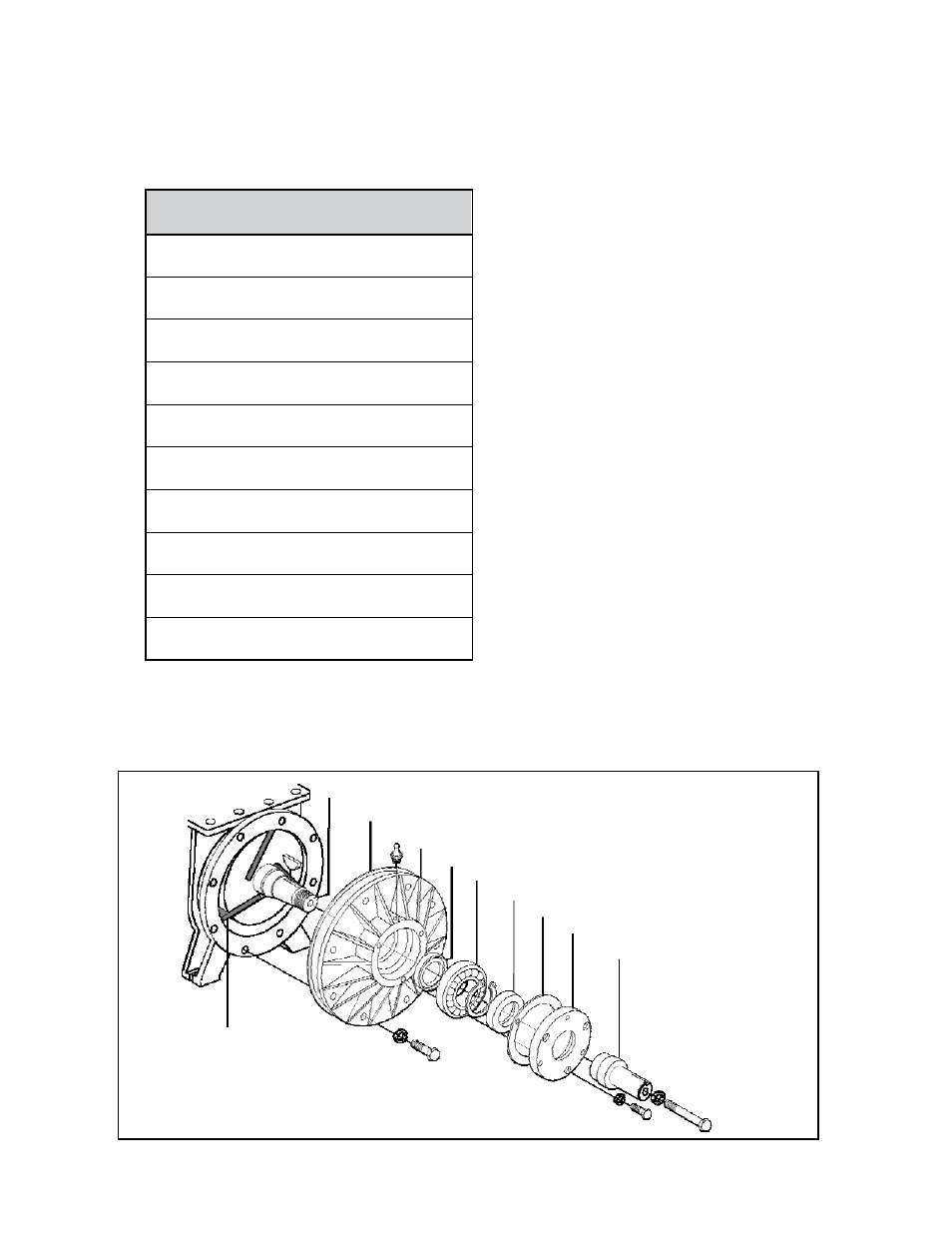

Checking the vanes the Conde vacuum

pump supplied with your slide-in unit

involves disassembling one of the end

Rotor Shaft

O-Ring

End Plate

Seal

Bearing

Seal

Gasket

Bearing Plate

Drive Shaft

Rotor Vanes

Figure 4.4 Slide-in Vacuum Pump – Front End

Checking Rotor Vane Wear

A

bl

29