Satellite Slide Tank User Manual

Page 18

Loading the Tank

case, increase the engine speed to

eliminate the vacuum pump vibration and

protect against vacuum pump damage.

With the pump in operation, use the

following procedure to load the tank on

your slide-in unit:

When the pump is running, check oil flow

in the drip oiler sight window to ensure

• Set the vacuum/pressure handle on

the pump to the “vacuum” mode.

that the proper lubrication is reaching the

pump (Figure 3.8). The minimum

recommended oiling rate is 30 drops per

minute. To increase oil flow, turn the

adjustment knob on the drip oiler

counterclockwise. To decrease oil flow,

turn the adjustment knob clockwise.

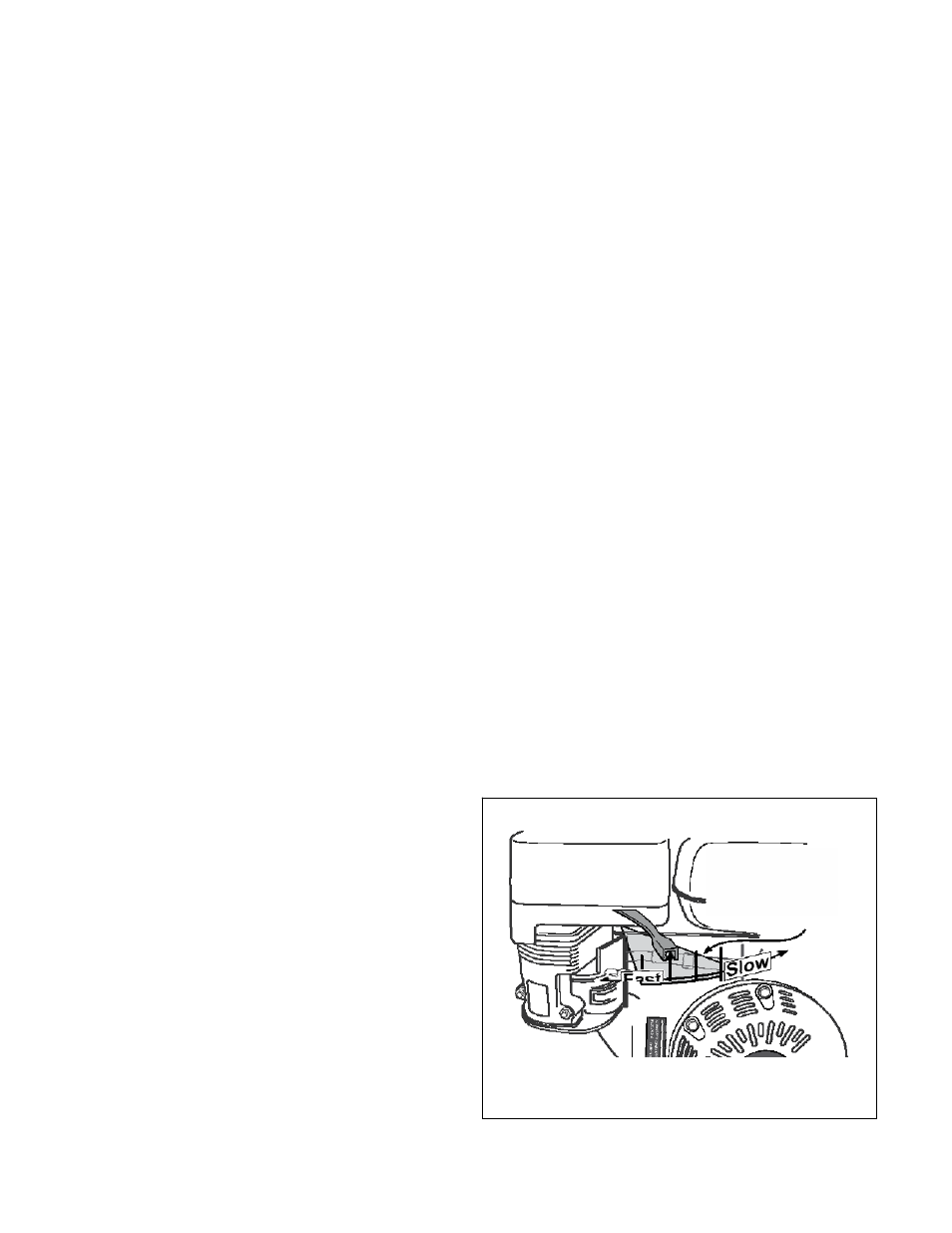

• Move the throttle control lever on the

gas engine to about 3/4 of the way

toward the FAST position (Figure 3.9).

This will provide the

recommended 1250

to 1300 rpm at the vacuum pump.

Moving the throttle lever all the way open

will result in about 1600 rpm-s at the

vacuum pump. Because this is over the

1300 rpm that the pump is rated for, the

engine throttle lever must be backed

down just a bit from the fill throttle

position.

Pay close attention to the drip rate of the

manual adjust drip oiler on your vacuum

pump, and regulate it as necessary.

Manual drip oilers require periodic

checking and adjustment. In addition,

readjust the drip oiler when changing oil

weight in your pump.

Making sure the throttle on the gas engine

is set to provide the optimum speed for the

pump requires the attentive observation of

the operator. If the pump is running too

slow the vanes will make a clanking sound

as they move in the rotor slots. If the pump

is running too fast it will overheat.

Finally, before using the pump to load the

tank, actuate the vacuum/pressure

handle to be sure that the pump is

operating in each mode.

`

NOTICE:

DO NOT run your vacuum

pump at too slow a speed when starting

it. If excessive vibration is evident, speed

up the gas engine drive until the pump

runs smoothly. Allowing the rotor vanes

to pound against the cylinder wall by

running at too slow a speed will damage

the vacuum pump.

• Allow the vacuum to build to the desired

level (usually about 15” Hg), and then

open the valve on the suction wand and

load the tank.

When running the

vacuum pump,

position the throttle

control lever on the

gas engine at

about ¾ of the way

IMPORTANT

: When adjusting your

vacuum pump oiler, use small adjustment

increments (no more than one turn at a

time). This helps protect against running

the pump dry due to turning the

adjustment knob too lean or in the wrong

direction.

`

NOTICE

: If proper oiling is not

achieved within a few minutes, shut down

pump and see “Trouble Shooting” section

on page 31 or consult your sales

representative.

Figure 3.9 Throttle Control Lever Operating

18