Satellite Slide Tank User Manual

Page 20

20

there is less pressure at hand to load your

tank. Table 3.4 lists the percentage loss of

attainable vacuum for every 1000-foot rise

in elevation over sea level.

While it is necessary to create enough

vacuum to handle pumping height, product

weight, and hose friction, it is important not

to overstress the pump. Pay close attention

to your pump if it is necessary to operate at

a high in./Hg vacuum level. Air- cooled

pumps are especially vulnerable to

overheating when being operated for

extended periods at high vacuum levels.

Liquid cooled pumps can handle this type

of operation much more readily.

In addition, operation at high in./Hg levels

can also result in moisture condensation in

the pump. As vacuum increases, water

begins to evaporate from the surface of the

liquid in the tank. Anytime that vacuum

pump operation exceeds 15"Hg, water

vapor can begin to show up in the air

circulating in the vacuum system.

While most of this moisture collects in the

oil catch muffler, some of it will also

accumulate inside the pump. In order to

prevent problems connected with water

collecting in your vacuum pump, dry it out

anytime that you notice that water has

collected in the oil catch muffler.

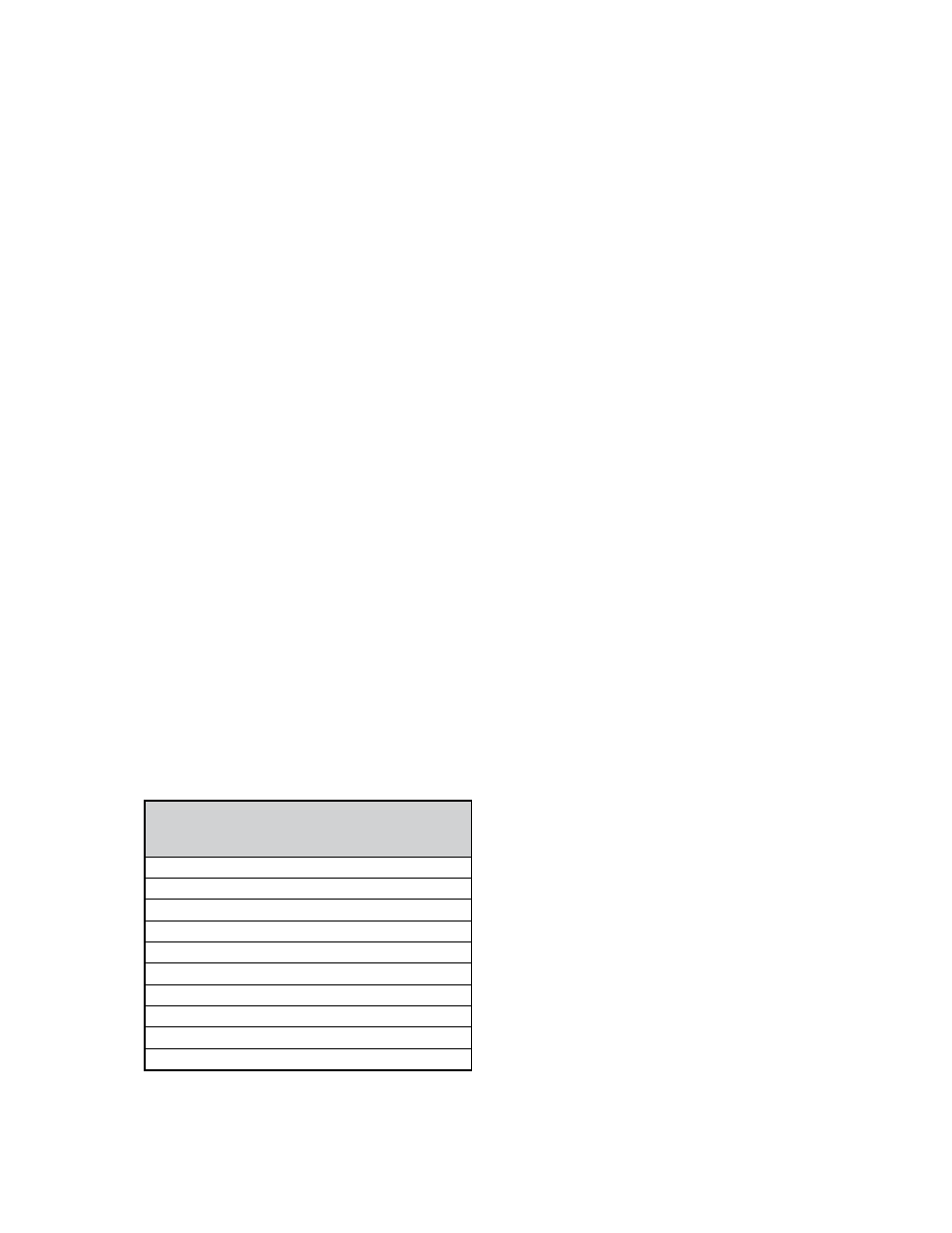

Table 3.4 Vacuum vs Elevation

Attainable

Percentage of

Elevation Maximum

loss

per

1,000

Vacuum Level

feet elevation

0

29.921 ----

1,000

28.85

3.6%

2,000

27.82

7.0%

3,000

26.82

10.4%

4,000

25.84

13.6%

5,000

24.89

16.8%

6,000

23.98

19.9%

7,000

23.06

22.9%

8,000

22.20

25.7%

9,000

21.38

28.5%

Use the following procedure to dry the

pump out:

• Unload the tank

• Open a load or dump valve (to keep from

building vacuum)

• Run the pump in vacuum mode for two

to five minutes

Water that is allowed to remain in your

vacuum pump can diminish performance

and cause serious damage. When water is

present inside the pump, sludge forms.

This can restrict the vanes from moving

freely inside the rotor slots, reducing the

efficiency of your pump. In addition, water

inside your vacuum pump can freeze

during cold weather operation. Attempting

to operate your pump if it is frozen inside

with ice will damage it.

`

NOTICE

DO NOT run your vacuum

pump above the pump manufacturer’s

maximum continuous vacuum rating.

Exceeding the maximum vacuum rating

could cause damage to the pump and/or

tank.

IMPORTANT:

After operating your

pump at high in./Hg vacuum levels, dry the

pump interior out using the procedure

outlined above. Water in your vacuum

pump can cause sludge formation and

freeze up in cold weather.

Unloading

You have two options when unloading the

tank on your slide-in unit, gravity dumping

or pressure dumping. Either method will

effectively empty the tank, however

pressure dumping increases discharge

flow rate.

Begin the unloading procedure by placing

the vacuum pump control handle into

neutral to relieve any vacuum in the

system, then use one of the following

procedures.

For gravity dumping, use the following