Satellite Slide Tank User Manual

Page 14

Pressure Relief Valve

A pressure relief valve is located in the

airline circuit next to the vacuum relief

valve (Figure 3.1). This valve serves to

prevent damage to the tank and motor. It

opens, to release air, when the pressure

in the tank reaches 6 psi. to 8 psi.

When the pressure relief valve opens to

release excess air, it creates a hissing

sound that you should be able to hear.

Listen for this sound, and if the valve

does not open at the above pressure,

14

reset it. Exceeding the recommended 6

psi. to 8 psi pressure can create

excessive horsepower draw on your

engine causing it to overheat.

CAUTION: DO NOT exceed a

maximum pressure of 6 psi to 8psi with

your vacuum tank. Exceeding the

pressure can create the engine to

overheat, which could result in damage to

equipment.

Use the following procedure to set the

pressure relief valve:

1. Purge all air from the tank by slowly

opening the rear dump valve. Stand off

to the side of the valve to prevent

possible injury from the direct flow of

releasing pressure.

2. After purging the tank of air, loosen the

setscrew located near the top of the

pressure relief valve. Rotate the inner

cylinder clockwise one to two revolutions

to reduce the setting at which the valve

opens. Retighten the setscrew after

making the adjustment.

3. Run the vacuum pump in the pressure

mode, and check to see if the valve

opens at the specified setting as listed

above.

4. Repeat steps one through three until

you attain the proper setting.

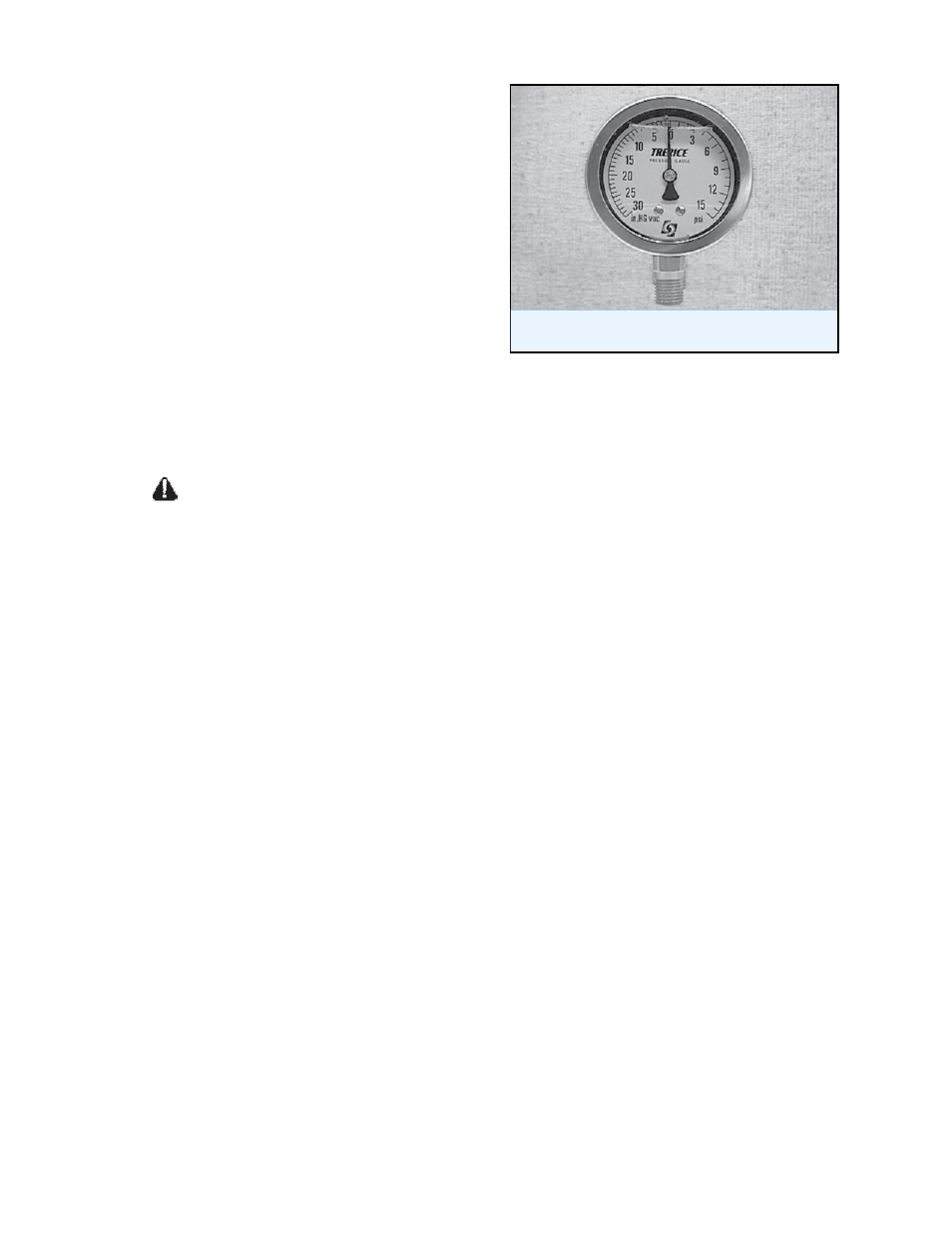

Figure 3.2 Vacuum / Pressure Gauge

Vacuum / Pressure Gauge

A vacuum/pressure gauge is located on

your tank (Figure 3.1). As the gauge

needle moves counterclockwise of zero,

the gauge reads vacuum in inches of

Mercury (in.Hg). As the gauge needle

moves clockwise of zero, the gauge reads

pressure in pounds per square inch (psi)

(Figure 3.2). Use the gauge to determine

when the tank has reached operating

vacuum or pressure.

Moisture Trap (Secondary Shutoff)

The moisture trap (also referred to as the

secondary shutoff) serves as a safety

device to prevent liquid from entering the

vacuum pump. Check the moisture trap

daily for accumulation of liquid. Use the

easy access drain valve to empty the

trap. The drain is located at the bottom of

the moisture trap.

While the moisture trap helps prevent

liquid from entering the pump, excess

accumulation may be an indicator that

some contamination has passed into the

pump. When excess liquid shows up in

your moisture trap, clean your vacuum

pump using the procedure on page 25 of

this manual.

IMPORTANT

: Anytime that excess

liquid accumulates in the moisture trap,

clean the inside of your pump. Liquid

contamination that enters the pump can