Carrier 33ZCFANTRM User Manual

Page 43

43

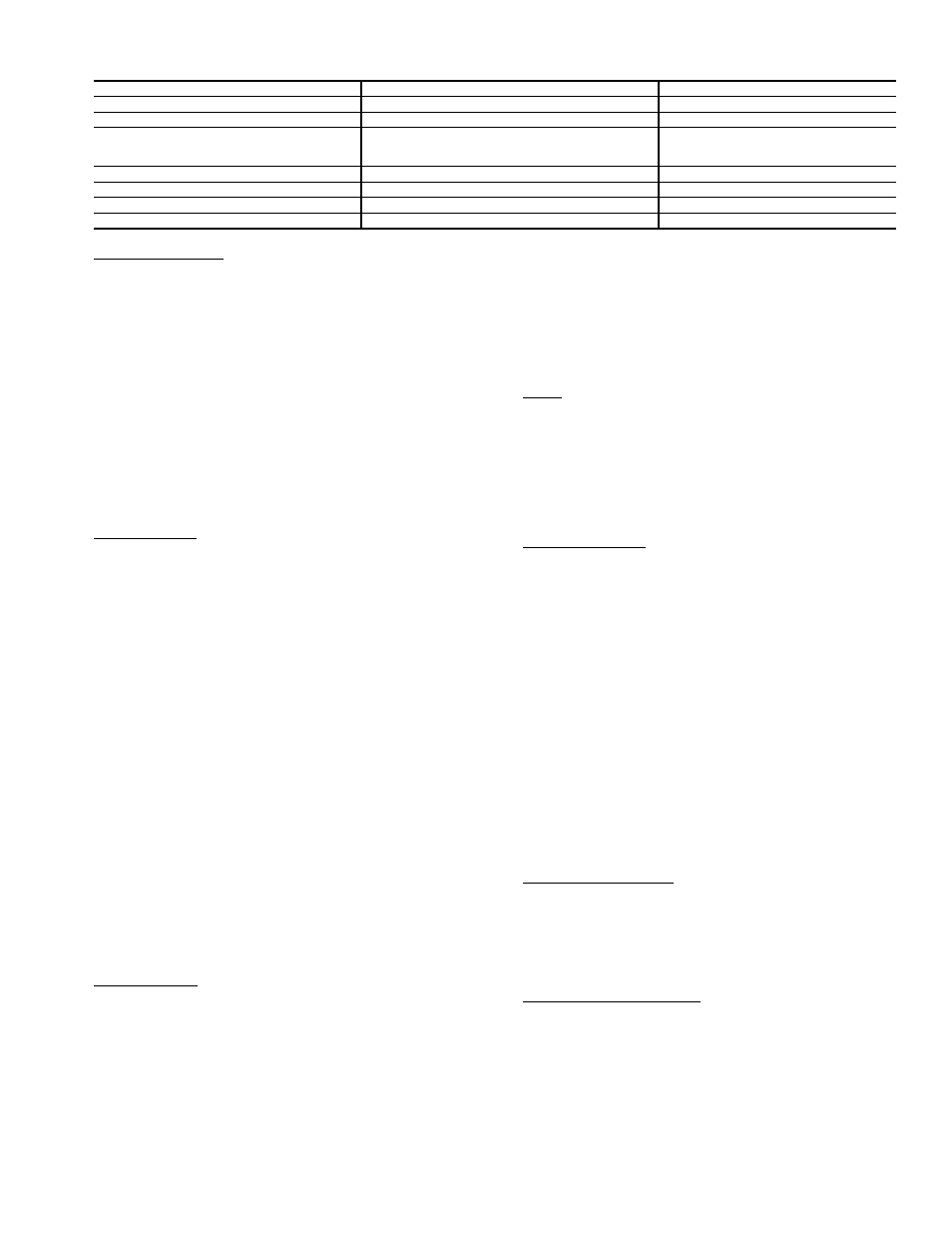

Table 12 — Secondary Damper Service Configuration Screen

Secondary Duct Size — The Secondary Duct Size setting is

used to input the inlet diameter of the terminal, if used with a

round inlet. The Inlet Area configuration is used for oval or

rectangular inlets. The zone controller will use the larger value

for CFM calculations if both values are configured.

Secondary Duct Size

(Inlet Diameter): Units

Inches

Range

3.0 to 24.0

Default Value

6.0

Inlet Area — The Inlet Area configuration is used if the termi-

nal has an oval or rectangular inlet. The Primary Inlet Size

configuration is used for round inlets. The zone controller will

use the larger value for CFM calculations if both values are

configured.

Inlet Area:

Units

Square Inches

Range

0.0 to 500.0

Default Value

0.0

Probe Multiplier — This configuration is used to input a fac-

tor for the velocity pressure probe characteristics installed in

the inlet. All averaging probes will have some aerodynamic

characteristics which will amplify the pressure difference read

at the inlet of the terminal. The default of 2.443 is the correct

value to use if the probe is a Carrier probe in a 35 or 45 Series

terminal.

The formula for calculating velocity using an Ideal probe is:

Velocity = 4005* SQRT (Velocity Pressure)

Most manufactures will provide a probe constant for the

probe supplied. For example, Velocity = 2213*SQRT(Velocity

Pressure). To calculate the number to input in this decision

(Probe Multiplier) use the formula. (4005/2213)

2

= 3.3. So you

would use 3.3 in place of 2.443 for a probe with a probe con-

stant of 2213.

An easy way to determine the probe constant for a probe

without documentation is to measure the velocity pressure with

a Magnahelic gage. Open the damper and adjust the static pres-

sure until you have one inch of velocity pressure on the Magna-

helic gage. Measure the total CFM of air being produced. The

CFM just measured divided by the inlet area in feet should

equal the probe constant for the formula. Velocity = (CFM just

measured/inlet area) * SQRT (1.0). Now use the constant that

was empirically derived to determine the probe multiplier

(4005/(CFM at 1.0 Inch/Inlet area))

2

= Probe Multiplier.

Probe Multiplier: Range

0.250 to 9.999

Default Value

2.443

Calibration Gain — Air terminal testing by industry standards

is done with straight duct, upstream of the terminal. Since most

applications do not get installed in this manner, the actual air-

flow from the terminal at balancing may not equal the reading

from the zone controller.

The calibration gain is used for the fine tuning adjustments

which might need to be made to the airflow calculation.

If the Calibration Gain must be configured manually. It is

determined as a percentage up or down that the CFM indicated

will be offset. A number of .95 will cause the maximum air-

flow calculated to be reduced to 95% of the value. A Calibra-

tion Gain of 1.00 will cause no change. A number of 1.05

would cause readings to become 5% higher.

Any error in reading at minimum airflow is adjusted by cal-

culating the Offset configuration value.

Calibration Gain: Range

0.000 to 9.999

Default Value

1.000

Offset — The Offset configuration is included for precision

applications where the minimum airflow is critical and not

zero. The cfm will be offset by the value entered in the Mini-

mum Cfm variable and will zero at the value entered in the

Maximum Cfm variable. There will be a linear relationship be-

tween the two set points.

Offset:

Units

cfm

Range

–250 to 250

Default Value

0

Clockwise Rotation — This configuration is used to define

what effect a clockwise rotation of the actuator will have on the

damper. If the actuator rotates clockwise to closed position, the

configuration should be set to Close. If the actuator rotates

clockwise to open, the configuration should be set to open.

This configuration is used to change the rotation of the actuator

so that the damper transducer calibration will work properly.

The actuator does not have to be reinstalled nor any switches

changed to reverse the action.

Clockwise

Rotation:

Range

Close/Open

Default Value

Close

Maintenance Table Menu Screen —

The Mainte-

nance Table Menu screen allows the user to select one of 4

available maintenance tables: the Linkage Maintenance Table,

the Occupancy Maintenance Table, the Zone Air Balance

Table, and the Zone Maintenance Table.

LINKAGE MAINTENANCE TABLE — The Linkage

Maintenance table is used to view the zone linkage variables.

See Table 13.

Air Source Bus Number — This variable will display the bus

number of the air source that the zone controller will be com-

municating Linkage to, if this zone is the Linkage Master.

Air Source

Bus Number:

Range

0 to 239

Default Value

0

Network Access None

Air Source Element Number — This variable will display the

Element Address of the Air Source that the zone controller

will be communicating Linkage to, if this zone is the Linkage

Master.

Air Source

Element Number: Display Range

1 to 239

Default Value

0

Network Access None

DESCRIPTION

DEFAULT

POINT NAME

Zone Pressure Control

Dsable

ZPCNTL

Dual Duct Type

0

DDTYPE

Secondary Duct Size

Inlet Diameter

Inlet Area

6.0 in.

0.0 sq. in.

SRNDSZ

SSQA

Probe Multiplier

2.443

SPMF

Calibration Gain

1.000

CAL_GAIN

Offset

0 cfm

SOFFSET

CW Rotation

Close

DMPDIR

501

→

→