Mount zone controller, Zone controller, Sensor cannot be used on the same zone controller – Carrier 33ZCFANTRM User Manual

Page 4

4

R E L A T I V E H U M I D I T Y S E N S O R — The

33AMSENRHS000 relative humidity sensor is required for

zone humidity control (dehumidification).

NOTE: The relative humidity sensor and CO

2

sensor cannot

be used on the same zone controller.

INDOOR AIR QUALITY (CO

2

) SENSOR — An indoor air

quality sensor is required for optional demand control ventila-

tion. The CGCDXSEN002A00 CO

2

Sensor is an indoor,

wall mounted sensor with an LED display. The

CGCDXSEN003A00 CO

2

Sensor is an indoor, wall mounted

sensor without display.

NOTE: The relative humidity sensor and CO

2

sensor cannot

be used on the same zone controller.

Mount Zone Controller

LOCATION — The zone controller must be mounted on the

air terminal’s damper actuator shaft. For service access, there

should be at least 12 in. of clearance between the front of the

zone controller and adjacent surfaces. Refer to Fig. 6.

MOUNTING — Perform the following steps to mount the

zone controller:

1. Visually inspect the damper and determine the direc-

tion in which the damper shaft moves to open the

damper — clockwise (CW) or counterclockwise

(CCW). Refer to Fig. 7.

If the damper rotates CCW to open, it does not require

any configuration changes.

If the damper rotates CW to open, then the damper

actuator logic must be reversed. This is done in the

software when performing system start-up and damper

calibration test. Do not attempt to change damper rota-

tion by changing wiring. This will upset the damper

position feedback potentiometer readings.

2. Rotate the damper shaft to the fully closed position.

Note direction of rotation.

3. Press the release button on the actuator and rotate the

clamp in the same direction that was required to close

the damper in Step 2.

4. Press the release button on the actuator and rotate the

actuator back one position graduation. Release the but-

ton and lock the actuator in this position.

5. Mount the zone controller to the terminal by sliding

the damper shaft through the actuator clamp assembly.

Secure the zone controller to the duct by installing

the screw provided through the grommet in the anti-

rotation tab. Be sure the floating grommet is in the

center of the slot. Failure to center the grommet may

cause the actuator to stick or bind.

6. Tighten the actuator clamp assembly to the damper

shaft. Secure by tightening the two 10-mm nuts.

7. If the damper has less than 90 degrees of travel

between the fully open and fully closed positions, then

a mechanical stop must be set on the actuator. The

mechanical stop prevents the damper from opening

past the maximum damper position. To set the

mechanical stop, perform the following procedure:

a.

Press the actuator release button and rotate the

damper to the fully open position.

b.

Using a Phillips screwdriver, loosen the appropri-

ate stop clamp screw.

c.

Move the stop clamp screw so that it contacts the

edge of the cam on the actuator. Secure the stop

clamp screw in this position by tightening the

screw.

8. Verify that the damper opens and closes. Press the

actuator release button and rotate the damper. Verify

that the damper does not rotate past the fully open

position. Release the button and lock the damper in the

fully open position.

HF23BJ042

Made in Switzerland

by Belimo Automation

LR 92800

NEMA 2

Class 2 Supply

LISTED

94D5

TENP IND &

REG. EQUIP.

24VAC/DC

50/60 Hz

3VA 2W

5K

WIP

yel

blu

ora

blk

red wht

COM

1

2

3

35 in-lb (4 Nm)

80...110s

0

1

J4

J3

J1

SR

VC

24V

AC

+

G

-

HIGH

3art Number: 33ZCFANTRM

S/N:

Bus#:

Element#:

Unit#:

J6

CCW

COM

CW

HEA

T

1

24V

AC

HEA

T

2

ZONE Controller

®

®

C

US

LOW

1

6

3

1

+

G

-

J2A

CCN

LEN

J2B

+

G

-

1

1

1

3

3

2

15

16

FAN AC

FAN

24VAC

N/A

HEAT3

J7

J6

1

1

2

3

ACTUATOR

CLAMP

ASSEMBLY

DAMPER

SHAFT

LOW PRESSURE

TUBING ROUTING

GROMMET

ANTI-

ROTATION

TAB

HIGH

PRESSURE

TUBING

ROUTING

ACTUATOR

RELEASE

BUTTON

MECHANICAL

STOP

RH/IAQ

GND

SECFLOW

+10V

DMPPOS

GND

TEST

GND

+24V

SPT

GND

SAT

T56

GND

PAT

REMOTE

CW

COM

COW

J8

SEC DMP

1

3

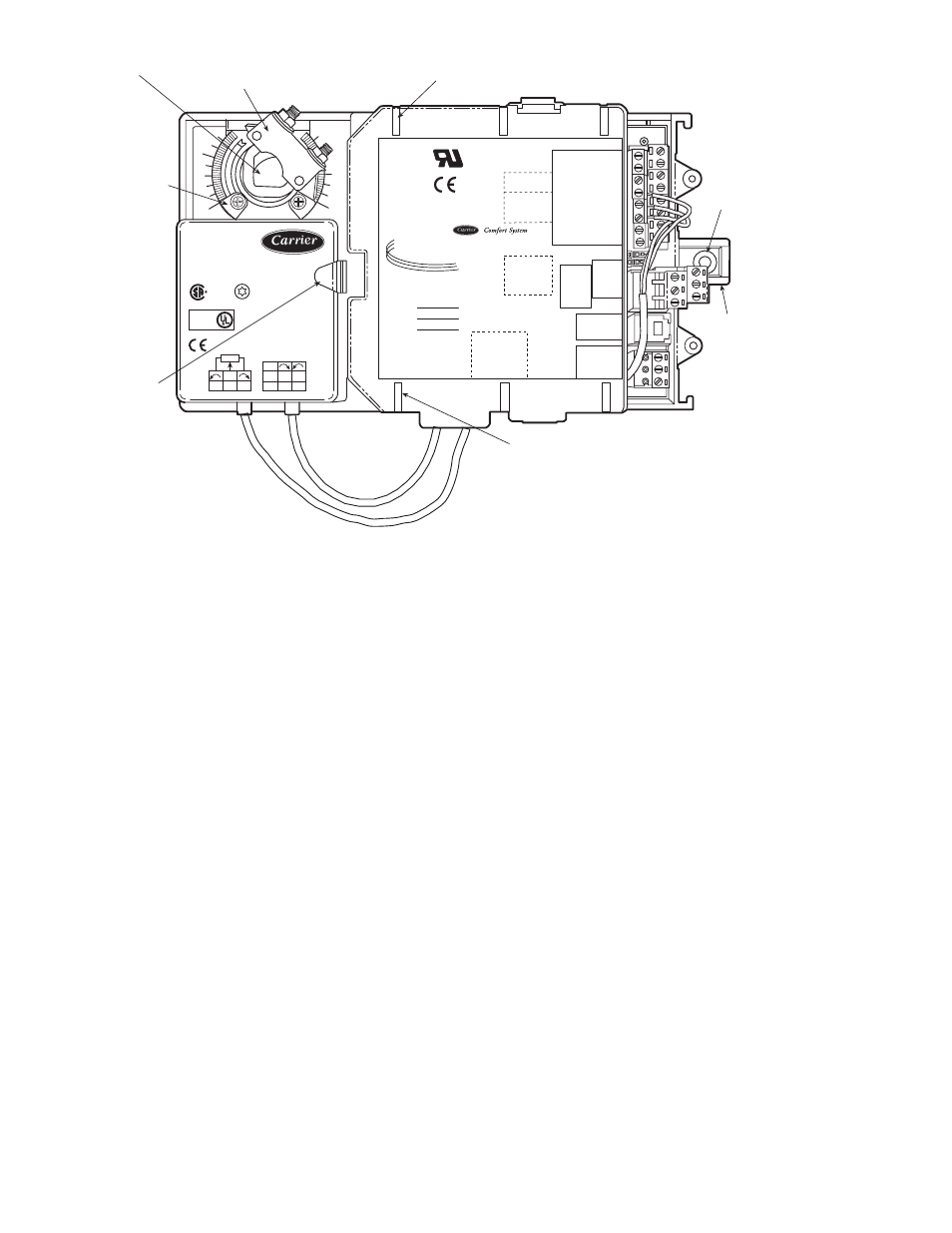

→ Fig. 2 — Zone Controller Physical Details (33ZCFANTRM Shown)

NOTE: Actuator clamp accepts dampers

shafts with the following characteristics:

Round —

1

/

4

-in. to

5

/

8

-in.

(6 to 16 mm)

Square —

1

/

4

-in. to

7

/

16

-in.

(6 to 11 mm)

Damper shaft must be a minimum of 1.5-in.

(38 mm) long.

801