Carrier 33ZCFANTRM User Manual

Page 41

41

Start Value:

Units

F (C)

Range

40 to 125

Default Value

80

Ducted Heat — The Ducted Heat configuration is used to con-

figure the terminal for ducted heat. If a local heat source is in

the duct and requires airflow to provide heat, set the Ducted

Heat configuration for yes.

Ducted Heat

Range

No/Yes

Default Value

Yes

Maximum Duct Temperature — This configuration is used to

configure the maximum supply-air temperature desirable for

heating the space. This will cause the heat to be modulated or

cycled using this value as the maximum temperature of the air

to be supplied.

Maximum Duct

Temperature:

Units

F (C)

Range

40 to 200

Default Value

110

Number of Electric Stages — This configuration is used to

define the number of stages of electric heat controlled by the

zone controller.

Number of

Electric Stages:

Range

1 to 3

Default Value

1

Heat On Delay — The Heat On Delay configuration is used to

define a delay from the time a parallel terminal fan is started

until the heat is activated.

Heat On Delay:

Units

minutes

Range

1 to 60

Default Value

2

Fan Off Delay — The Fan Off Delay configuration is used to

define a delay time. The delay time is from when the heat is de-

activated (in a parallel terminal) until the parallel fan is deacti-

vated. This allows the fan to circulate air and remove the resid-

ual heat from the heat source.

Fan Off Delay:

Units

minutes

Range

1 to 15

Default Value

2

Two-Position Heat Logic — This configuration is used for

controlling a normally closed or normally open valve for hot

water. Use normal logic if the valve is normally closed. Use in-

verted logic if the valve is normally open.

Two Position

Heat Logic:

Range

Normal/Invert

Default Value

Normal

Space Temperature Trim — This configuration is used to trim

a space sensor which might need calibration. For example, if

the temperature displayed is two degrees above the value mea-

sured with calibrated test equipment, input a value of –2.0.

Space Temperature

Trim:

Units

delta F (delta C)

Range

–9.9 to 9.9

Default Value

0.0

Supply Air Temperature Trim — This configuration is used

to trim a supply air sensor which might need calibration. For

example, if the temperature displayed is two degrees above the

value measured with calibrated test equipment, input a value of

–2.0.

Supply Air Temperature

Trim:

Units

delta F (delta C)

Range

–9.9 to 9.9

Default Value

0.0

Remote Contact Config — The remote timeclock contact in-

put can be configured as a normally open or normally closed

contact. When the timeclock input is ‘On’ the zone will follow

it’s local occupancy schedule. When the timeclock input is

‘Off’ the zone will be forced into unoccupied state.

Remote Contact

Config:

Range

Close/Open

Default Value

Close

OPTIONS SERVICE CONFIGURATION SCREEN —

The Options Service Configuration screen is used to configure

the service options of the air terminal controller. See Table 11.

Occupancy Schedule Number — The Occupancy Schedule

Number defines what Occupancy schedule the zone controller

will use. Occupancy Schedule 64 is a local schedule. Occupan-

cy Schedules 65 to 99 are global schedules.

Occupancy Schedule

Number:

Range

64 to 99

Default Value

64

Global Schedule Master — The Global Schedule Master con-

figuration allows the Occupancy Schedule to be used as a Glo-

bal Schedule Master (Occupancy Schedules 65-99).

Global Schedule

Master:

Range

No/Yes

Default Value

No

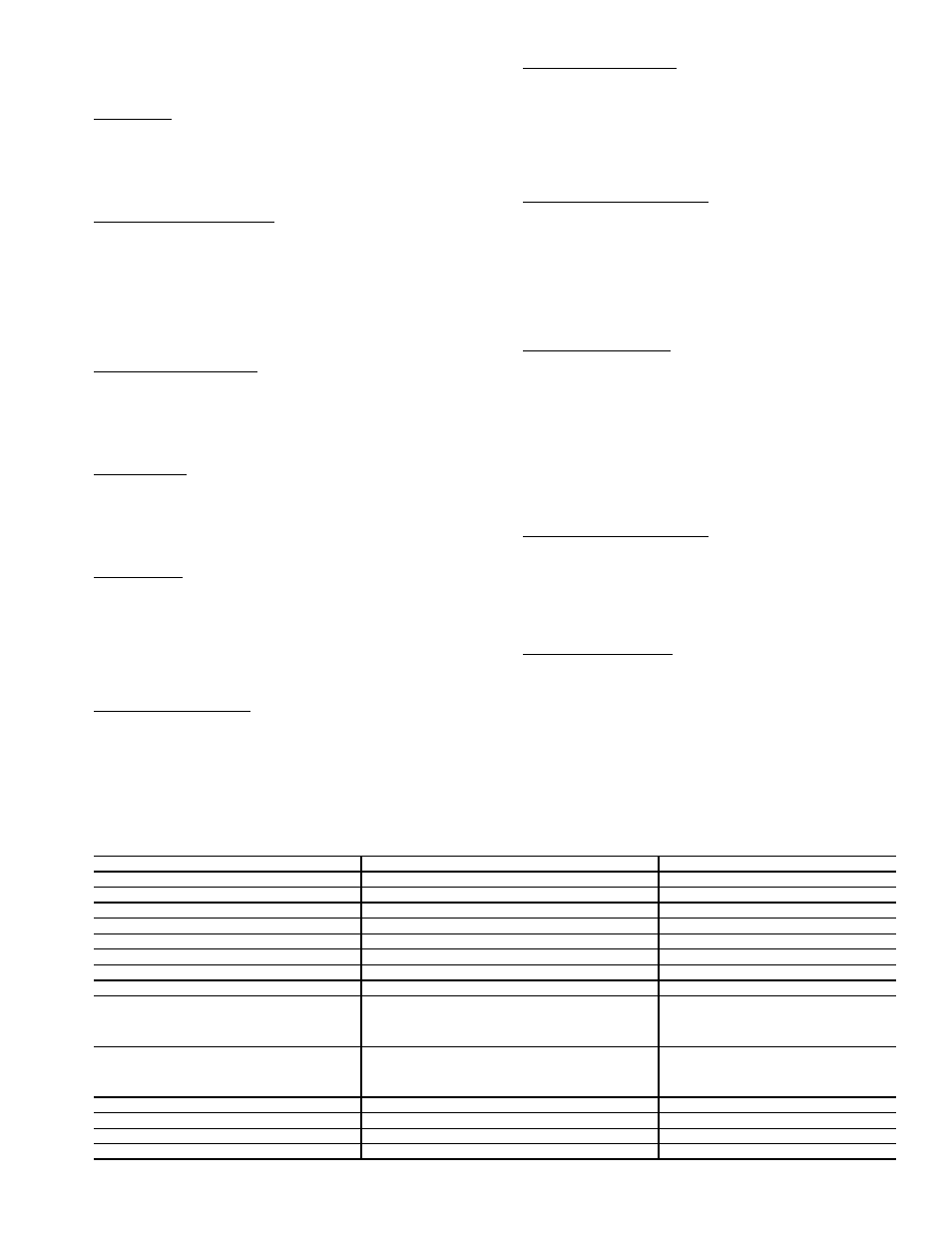

Table 11 — Options Service Configuration Screen

DESCRIPTION

DEFAULT

POINT NAME

Occupancy Schedule Number

64

SCH

Global Schedule Master

No

GSM

Override

00:00

OVR

Broadcast Acknowledge

No

BCACK

Set Point Group Number

0

SETT

Global Set Point Master

No

GSTM

Maximum Offset Adjust

2 F

LIMT

Control Options

0

CTLOPT

Humidity

Proportional Gain

Integral Gain

Maximum Output Value

1.5

0.30

100.0 cfm

KP

KI

MAXOUT

Air Quality

Proportional Gain

Integral Gain

Maximum Output Value

0.10

0.03

100.0 cfm

KP

KI

MAXOUT

AQ Low Voltage

0.0

AQINLO

AQ High Voltage

10.0

AQINHI

AQ Low Reference

0 ppm

AQLO

AQ High Reference

2000 ppm

AQHI

801

→