3 setting the digital filter parameters, 8 analog output calibration, Setting the digital filter parameters – Rice Lake SURVIVOR 420HE Hostile Environment - Installation Manual User Manual

Page 50: Figure 7.8 46 for an

46

420HE Installation Manual

7.7.3

Setting the Digital Filter Parameters

Fine-tuning the digital filter parameters greatly

improves indicator performance in heavy-vibration

environments. Use the following procedure to

determine vibration effects on the scale and optimize

the digital filtering configuration.

1. In setup mode, set all three digital filters

( D I G F L 1 , D I G F L 2 , D I G F L 3 ) t o 1 . S e t

DFTHRH to NONE. Return indicator to

normal mode.

2. Remove all weight from the scale, then watch

t h e i n d i c a t o r d i s p l a y t o d e t e r m i n e t h e

magnitude of vibration effects on the scale.

Record the weight below which all but a few

readings fall. This value is used to calculate the

DFTHRH parameter value in Step 4.

For example, if a heavy-capacity scale

produces vibration-related readings of up to 50

lb, with occasional spikes to 75 lb, record 50 lb

as the threshold weight value.

3. Place the indicator in setup mode and set the

digital filters (DIGFLx) to eliminate the

v i b r a t i o n e ff e c t s o n t h e s c a l e . ( L e a v e

DFTHRH set to NONE.) Reconfigure as

necessary to find the lowest effective values

for the DIGFLx parameters.

4. With optimum values assigned to the DIGFLx

parameters, calculate the DFTHRH parameter

value by converting the weight value recorded

in Step 2 to display divisions:

threshold_weight_value / DSPDIV

In the example in Step 2, with a threshold

weight value of 50 lb and a display division

value of 5lb:

50 / 5lb = 10DD.

DFTHRH should

be set to 10DD for this example.

5. Finally, set the DFSENS parameter high

enough to ignore transient peaks. Longer

transients (typically caused by lower vibration

frequencies) will cause more consecutive

out-of-band readings, so DFSENS should be

set higher to counter low frequency transients.

Reconfigure as necessary to find the lowest

effective value for the DFSENS parameter.

7.8

Analog Output Calibration

The following calibration procedure requires a multimeter to measure voltage or current output from the analog

output module. If the option is not already installed, see Section 2.3.5 on page 8.

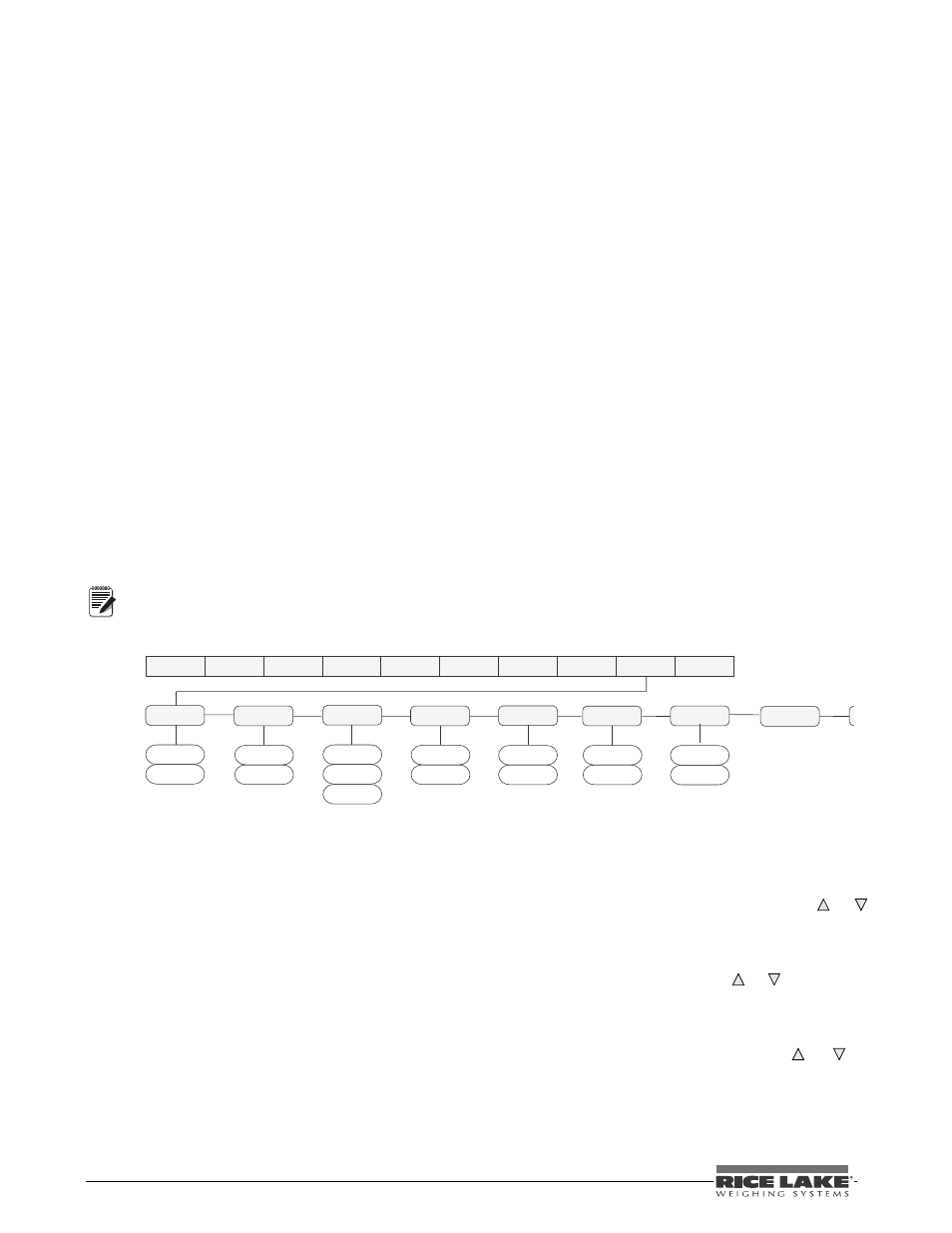

XXXXXXX

XXXXXXX

ALGOUT

DIGIN

SETPNT

XXXXXXX

PROGRM

PFORMT

SERIAL

CALIBR

XXXXXXX

CONFIG

FORMAT

SOURCE

GROSS

0%

20%

OFFSET

ERRACT

FULLSC

HOLD

000000

number

MIN

10000

number

MAX

TWZERO

NET

ZEROSC

VERS

MINNEG

OFF

ON

MAXNEG

OFF

ON

Note

The analog output must be calibrated after the indicator itself has been configured (Section 3.0) and

calibrated (Section 4.0).

Figure 7-5. Analog Output Menu

1. Enter setup mode and go to the ALGOUT

menu (see Figure 7-5).

•

Set OFFSET to 0% for 0–10 V output,

20% for 4–20 mA output

•

Set MIN to lowest weight value to be

tracked by the analog output

•

Set MAX to highest weight value to be

tracked by the analog output

2. Connect multimeter to analog output:

•

For voltage output, connect voltmeter

leads to pins three and four

•

For current output, connect ammeter leads

to pins one and two

3. Adjust zero calibration: Scroll to the

TWZERO parameter. Check voltage or current

reading on multimeter. Press and hold or

to adjust the zero value up or down.

4. Adjust span calibration: Scroll to the TWSPAN

parameter. Check voltage or current reading on

multimeter. Press and hold or to adjust the

span value up or down.

5. Final zero calibration: Return to the TWZERO

parameter and verify that the zero calibration

has not drifted. Press and hold or to

re-adjust the zero value as required.

6. Return to normal mode. Analog output

function can be verified using test weights.