0 customer or product id and load/deliver, 1 setting the customer or product id, Customer or product id and load/deliver – Rice Lake Combination System - Precision Loads PL9710 Indicator User Manual

Page 14: Setting the customer or product id, Using the customer or product id with load/deliver

10

PL9710 Installation Manual

5.0 Customer or Product ID and Load/Deliver

When the Load/Deliver mode has been enabled (See “Advanced Setup” on page 22.), each customer account or

product being loaded or delivered will need a unique identification (ID) number. The ID number can be selected

prior to pickup or delivery by using either the indicator keypad, an external keypad, or an optional bar-code

scanner.

5.1 Setting the Customer or Product ID

1. Press the

Menu

key for about 7 seconds until the

information display shows Setup ID.

2. After releasing the

Menu

key, the information

display will show ID Number selection.

3. Press the

Add

softkey to add an ID number.

The information display will show Add ID.

Record #001 and the last number of the weight

display will be flashing, telling you that number

is ready to be changed.

4. To change the number’s value, press the

Up

or

Down

key. To select a different number, press the

left arrow

or

right arrow

key.

5. Press the

Enter

key when finished.

The information display will show Store ID

Number. If the entered number has already been

selected, the information display will show Error

- Duplicate Number and you should enter a

different number.

6. When the correct number has been entered, press

the

Cancel

key.

The information display will show ID Number

selection.

Press the

Cancel

key again to return to normal

operation.

5.2 Using the Customer or Product ID with

Load/Deliver

Calibrate the

PL9710

indicator as outlined in Chapter 3,

Calibration, using 00000 for EMPTY weights. Enter

the net payload values obtained from a certified scale

for the FULL values. When calibrating the system, fill

the trailer with payload to no less than 80% of the

maximum full load. Since the empty weights are set at

00000 during calibration, the gross-weight reading will

be the same as the net-weight reading.

In the single-channel mode, the Accumulator function

can be used to add (or subtract, if delivering) each

individual pickup to previous pickups and store the

accumulated total in the indicator’s internal memory.

At the end of the job, a grand total of all pickups is

available.

A paper ticket can also be printed for each individual

pickup or delivery if a printer is attached and enabled

through the serial port at the back of the indicator (See

“Using the Serial Ports” on page 12.). The paper ticket

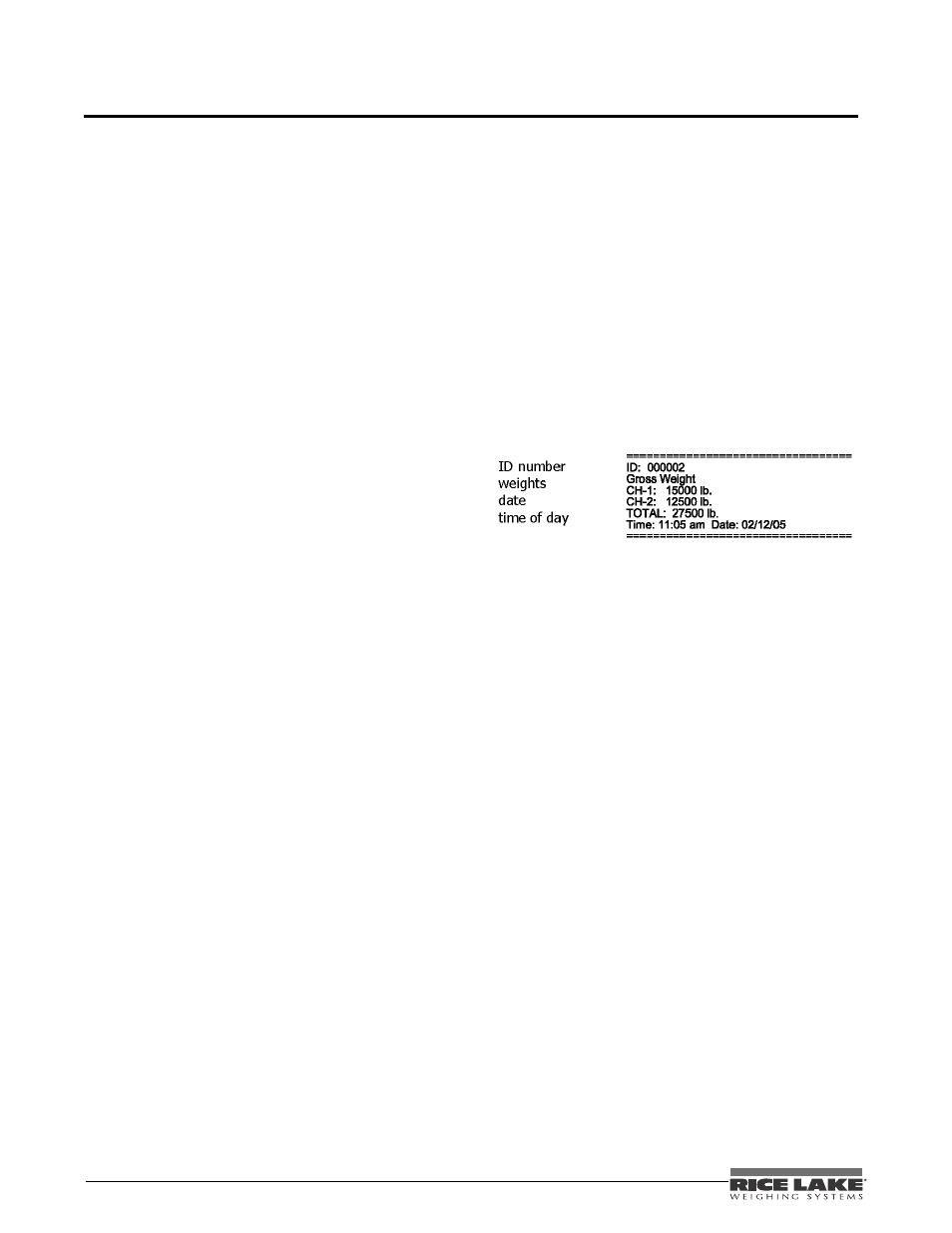

will show:

• ID number

• Weights

• Date

• Time of day

Figure 5-1. Paper Ticket Example

The Accumulator function is not available in the

2-channel mode but paper tickets may be printed with a

properly attached and enabled printer.

The following steps will guide you in using the

customer or product ID in the Load/Deliver mode.

For single-channel operation, make sure Accumulator

(if desired) and Load/Deliver have been enabled. See

1. Select Load/Deliver by pressing the

LD

softkey.

The red LED labeled LD at the left of the weight

display should be lit.

2. Select the correct customer or product ID by

pressing the

ID

softkey.

The information display will briefly show Select

ID number and then show Select ID.

Use the

Up

and

Down

keys until the correct ID

shows in the weight display and then press the

Select

softkey.

3. Before picking up or delivering each load, press

the

Zero

key.

As each load or delivery is made, the net weight

shown in the information display will increase or

decrease to show the total of all the pickups or

deliveries.