26 glazing – Oldcastle BuildingEnvelope Reliance-TC User Manual

Page 26

GLAZING

R E L I A N C E - T C C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

TM

Glazing Instructions

Location of Temporary

3" typ.

3" typ.

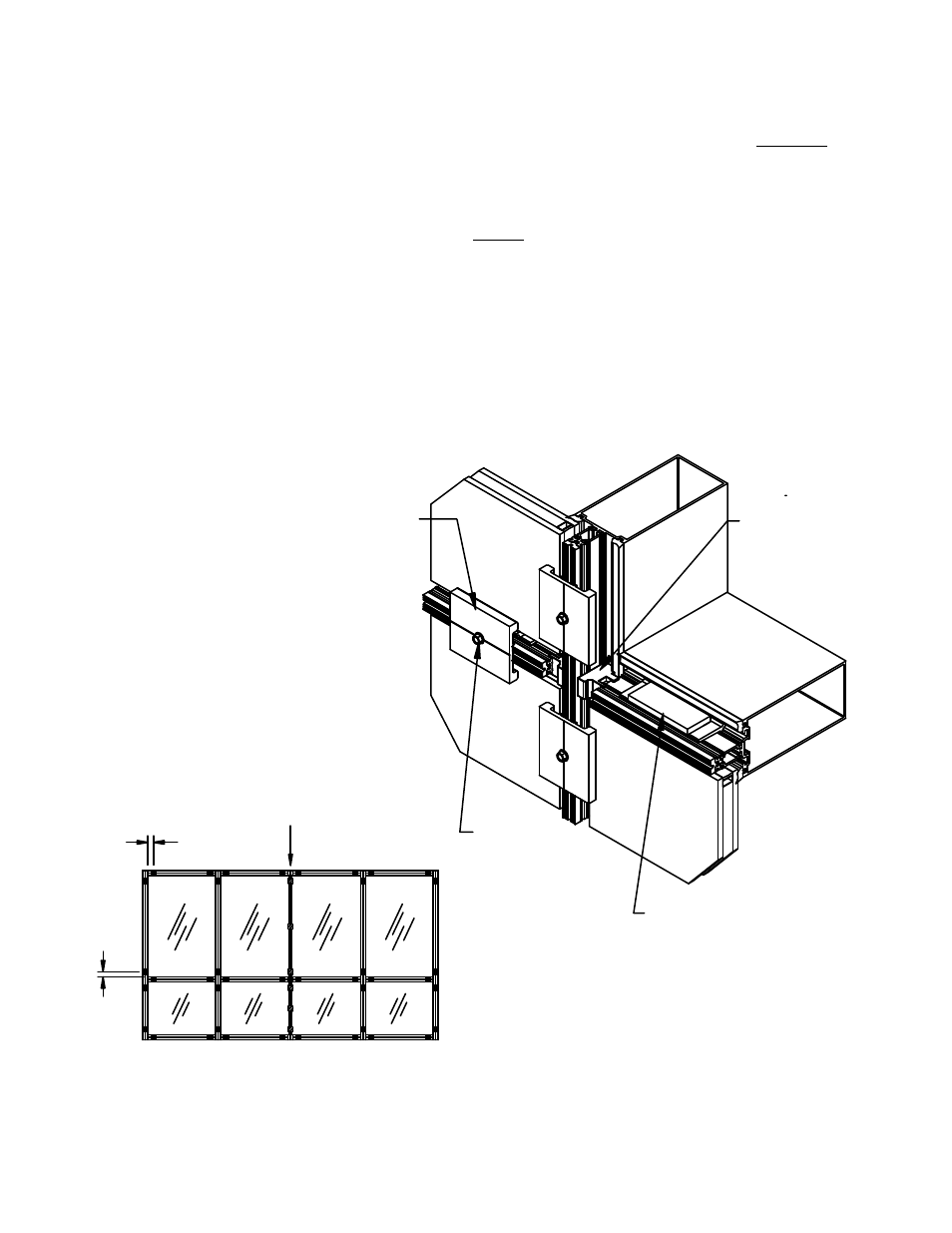

Glazing Retainers for Type II

SSG MULLION

FIGURE 24

FIGURE 23

MAY 2013

26

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

3.8 When glazing Type II, set glass in opening, make sure that glass bite is equal on all sides. CAUTION: BE

certain that glass is placed firmly against interior gasket to ensure a proper seal and to avoid binding

of the glass on the setting block.

3.9 Temporarily hold glass in the opening with WW-333 temporary glazing retainers & FS-325 screw. Use

SPW-PP-3 retainer for SSG verticals. Torque the FS-325 screw to 60 in-lbs.

· WW-333 temporary glazing retainers must be applied at each glass edge 3" from the corner (minimum of 8

per lite). Glass edges greater than 4' in length but less than 8' require an additional retainer at the glass

mid-span.

· Retainers are intended for short term use only. Additional retainers may be required to withstand full design

wind load pressures.

· Full length pressure plates must be installed if severe weather or high wind loads are anticipated. SEE

FIGURE 23 & 24.

WW-333-01 temporary glazing retainer.

Locate at 3" from edge of glass. Additional

clips may be required based on field

conditions and glass size.

WW-370 zone plug

see FIGURE 10 for

sealant notes

FS-325

(1) per retainer

AW-127 setting chair w/

GP-116 setting block

(2) per D.L.O, locate at

1/4 points