11 frame fab – Oldcastle BuildingEnvelope Reliance-TC User Manual

Page 11

FRAME FABRICATION

R E L I A N C E - T C C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

TM

3

4

"

Tubular Horizontal

DJ-100 DRILL JIG

23

32

"

Head, Sill & Roll-Over Horizontal

HEAD/SILL

/

RO

LL-OV

ER

23

/32"

HO

RIZO

NTAL

3/4"

HEAD/SILL/

ROLL-OVER

23/32"

HORIZONTAL

3/4"

11

16

"

11

16

"

11

16

"

11

16

"

5/16"Ø WEEP HOLE

CENTERLINE OF D.L.O.

7

32

""

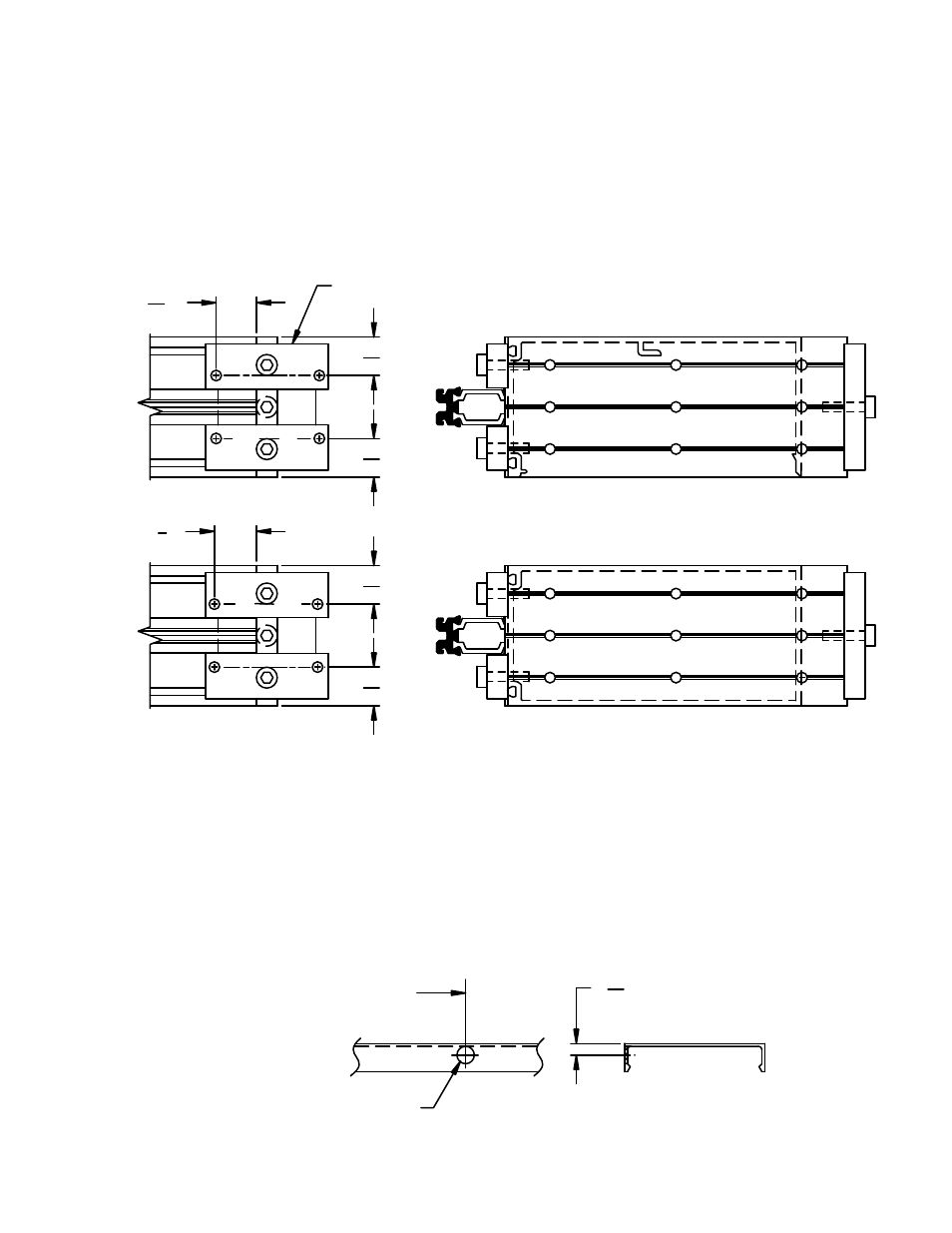

FIGURE 4

Type I & II Horizontal

Fabrication

FIGURE 5

Horizontal Face Cover Fabrication

C

A

C

RELIANCE CURTAIN WALL DJ-100 C

D

B

D

C

A

C

MAY 2013

11

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

1.4 Install and seal end caps to top and bottom of all jamb and intermediate vertical mullions with FS-320 #10 x 1/2"

drive screw. Cap seal FS-320. SEE FIGURE 3 page 10

.

1.5 Fabricate ends of horizontal members for shear block screws using DJ-100 drill jig. SEE FIGURE 4.

Note: When fabricating tubular (one-piece) horizontals, use the side of the drill jig stamped "Horizontal".

When fabricating head, sill and roll-over horizontals, use the side stamped "Head/Sill Rollover".

1.6 Drill 5/16" diameter weep holes at 1/4 points in the horizontal pressure plate. Drill (1) 5/16" diameter weep hole

at the bottom of each horizontal face cover at centerline of D.L.O. SEE FIGURE 5

.

NOTE: For SSG applications,

face covers typically run across mullions, so there will be multiple holes in each horizontal face cover.

1.7 All pressure plates have factory-punched holes for screws at 9" O.C typical. To ensure proper pressure on the

glazing, 7/32" diameter holes may need to be drilled at the ends of each horizontal pressure plate as required.

Locate at 1 1/2" maximum from the ends.