6 thermal design considerations, 1 thermal management, 2 heat spreader dimensions – Kontron SMARC-sAT30 User Manual

Page 76: Figure 16: heat spreader, Thermal design considerations, Thermal management, Heat spreader dimensions, 6thermal design considerations

User’s Guide

76

6

Thermal Design Considerations

6.1

Thermal Management

An optional heat spreader plate assembly is available from Kontron for the SMARC sAT30 module. The heat spreader

plate on top of this assembly is NOT a heat sink. It works as a SMARC®- standard thermal interface to be used with a

heat sink or other cooling device.

External cooling must be provided to maintain the heat spreader plate at proper operating temperatures. Under worst-

case conditions, the cooling mechanism must maintain an ambient air and heat spreader plate temperature of 60° C or

less.

The aluminum slugs and thermal pads on the underside of the heat spreader assembly implement thermal interfaces

between the heat spreader plate and the major heat-generating components on the sAT30 Module. About 80% of the

power dissipated within the module is conducted to the heatspreader plate and can be removed by the cooling

solution.

You can use passive thermal-management solutions with the heatspreader plates. The optimum cooling solution

varies, depending on the SMARC® application and environmental conditions.

6.2

Heat Spreader Dimensions

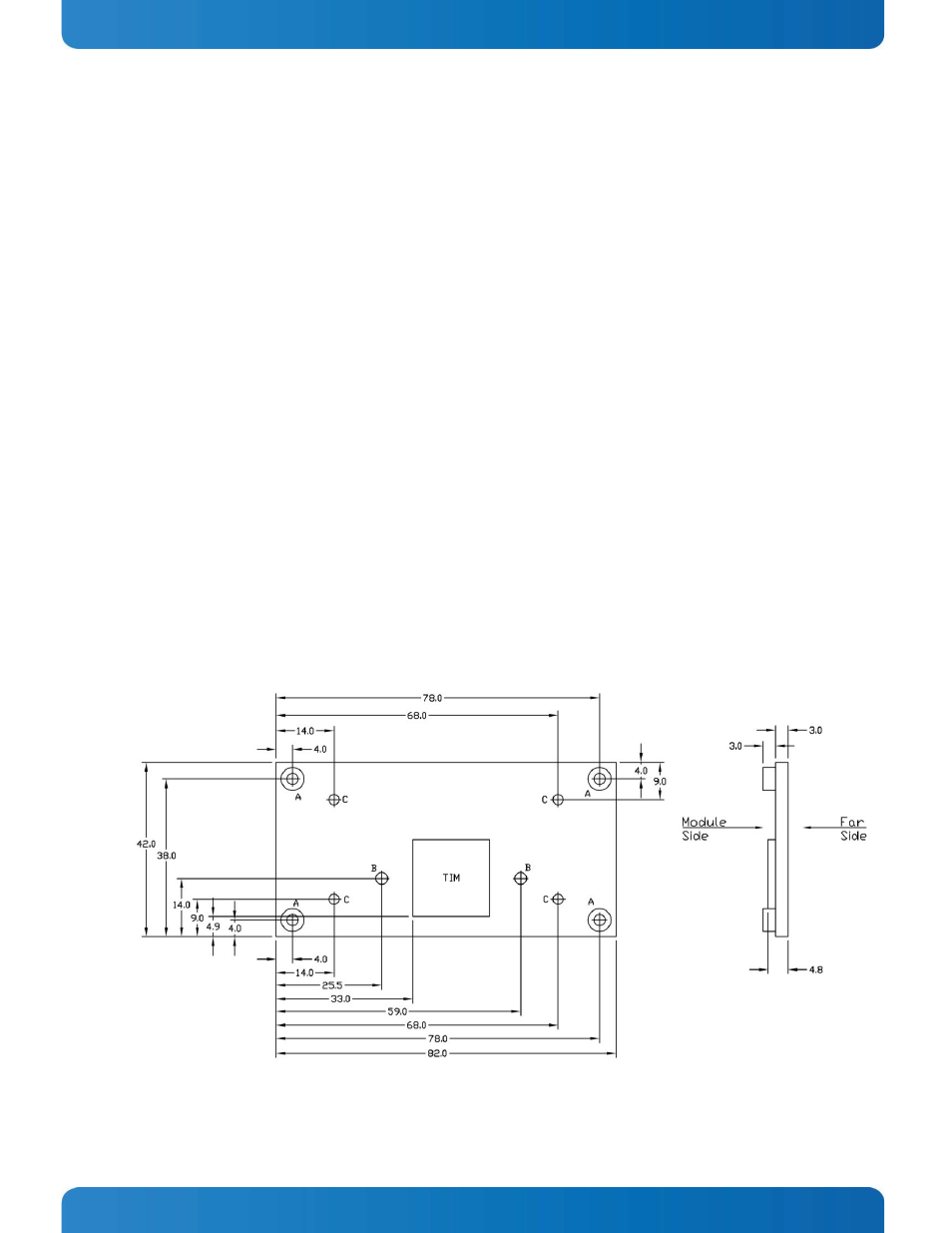

The SMARC sAT30 module includes two mounting holes for mounting the passive heat sink, located to the left and

right of the T30 SoC. Heat spreader dimensions are shown in the diagram below. (TIM” stands for Thermal Interface

Material)

Figure 16: Heat Spreader