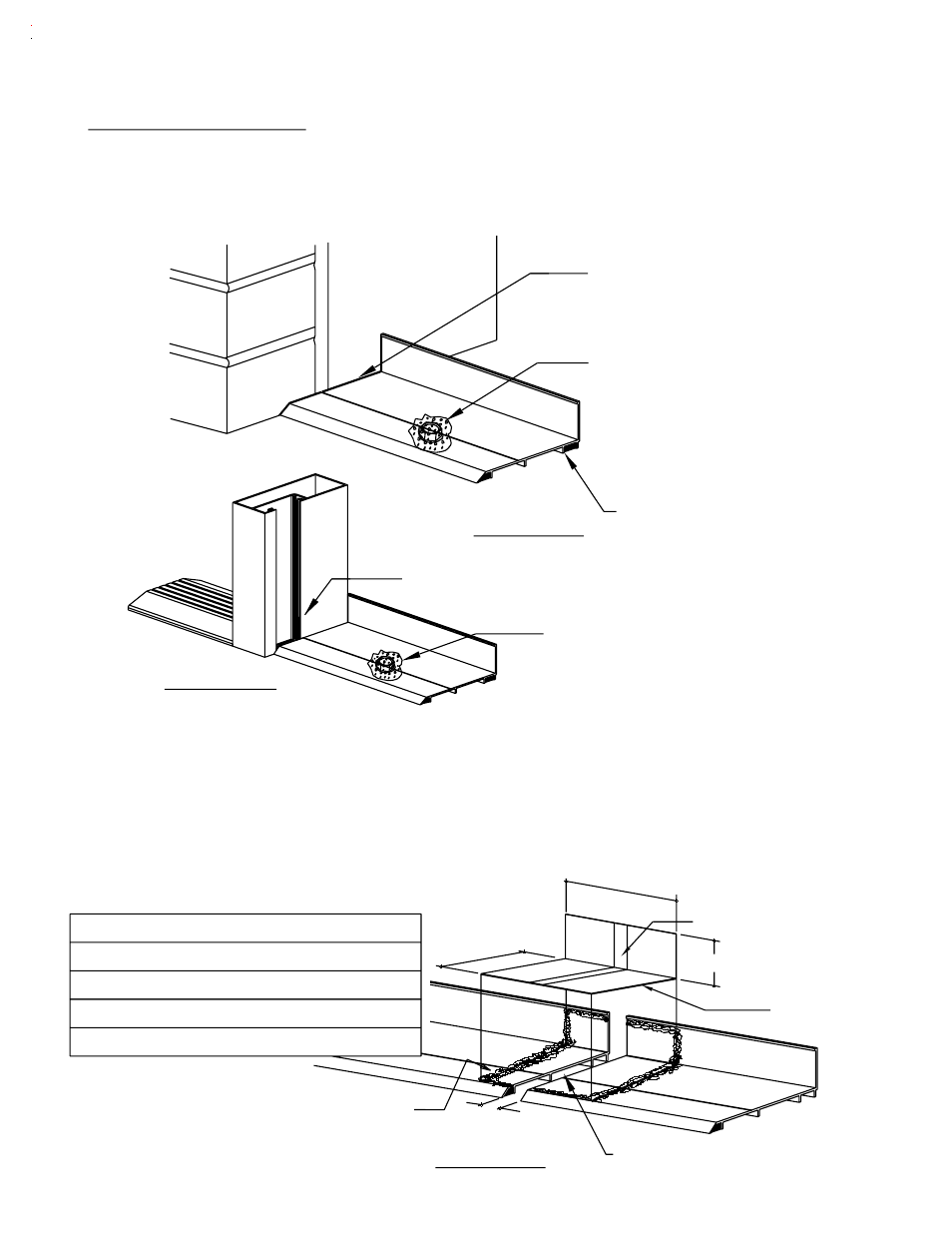

Sill flashing installation, F) typical detail showing parts relationship, Step 2) – EFCO 960 Series User Manual

Page 44: Step 1), Fig. # 35, Fig. # 34, Fig. # 33

Anchor the sill flashing 24" O.C. and

best performance, locate the sill flashing splice 6" from vertical

If the elevation’s configuration consists of verticals through, for

cover the heads of all attachment

screws with sealant.

MINIMUM

Splice the sill flashing every 20’-0" as shown in Fig. # 35 below.

F-542 splice sleeve is supplied for use with the 4 13/16" back

member. Trim F-542 to the correct length for the particular

9982 - 3 3/4" TRIMMED

F960 WALL

9972 - 2 13/16" TRIMMED

Set the sill flashing splice in a bed

of sealant around the perimeter

of the splice.

3/8"

FIG. # 35

STEP 2)

SILL FLASHING NUMBER & LENGTH

9974 - 6 1/16" AS SUPPLIED

9668 - 5 5/16" TRIMMED

intermediates.

SEE

CHART

system depth being used.

FIG. # 34

formed sleeve

silicone to fill the joint.

Use backer rod and

JDA 6/2002

.050 aluminum

1" wide centered on splice.

1 1/2"

Bond breaker tape

6"

SECTION VII - SILL FLASHING INSTALLATION

"skinning", nonhardening type of

screws with sealant.

sealant (i.e., silicone).

Seal the ends of the sill flashing with a

Cover the heads of all attachment

Fill the vertical glazing pocket with sealant

to divert water onto the sill flashing.

door frame to masonry. Refer to Fig. # 33 & # 34 below.

Install the sill flashing continuously between the masonry jambs or

FIG. # 33

STEP 1)

and set it in a continuous bead

Shim the sill flashing until it is level

of sealant.

PAGE 42

Before the fastener is inserted,

force sealant into the hole for the

that the hole through the sill

sill perimeter fastener to ensure

flashing is sealed.