Vermont Casting SDDVRBS User Manual

Page 34

34

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

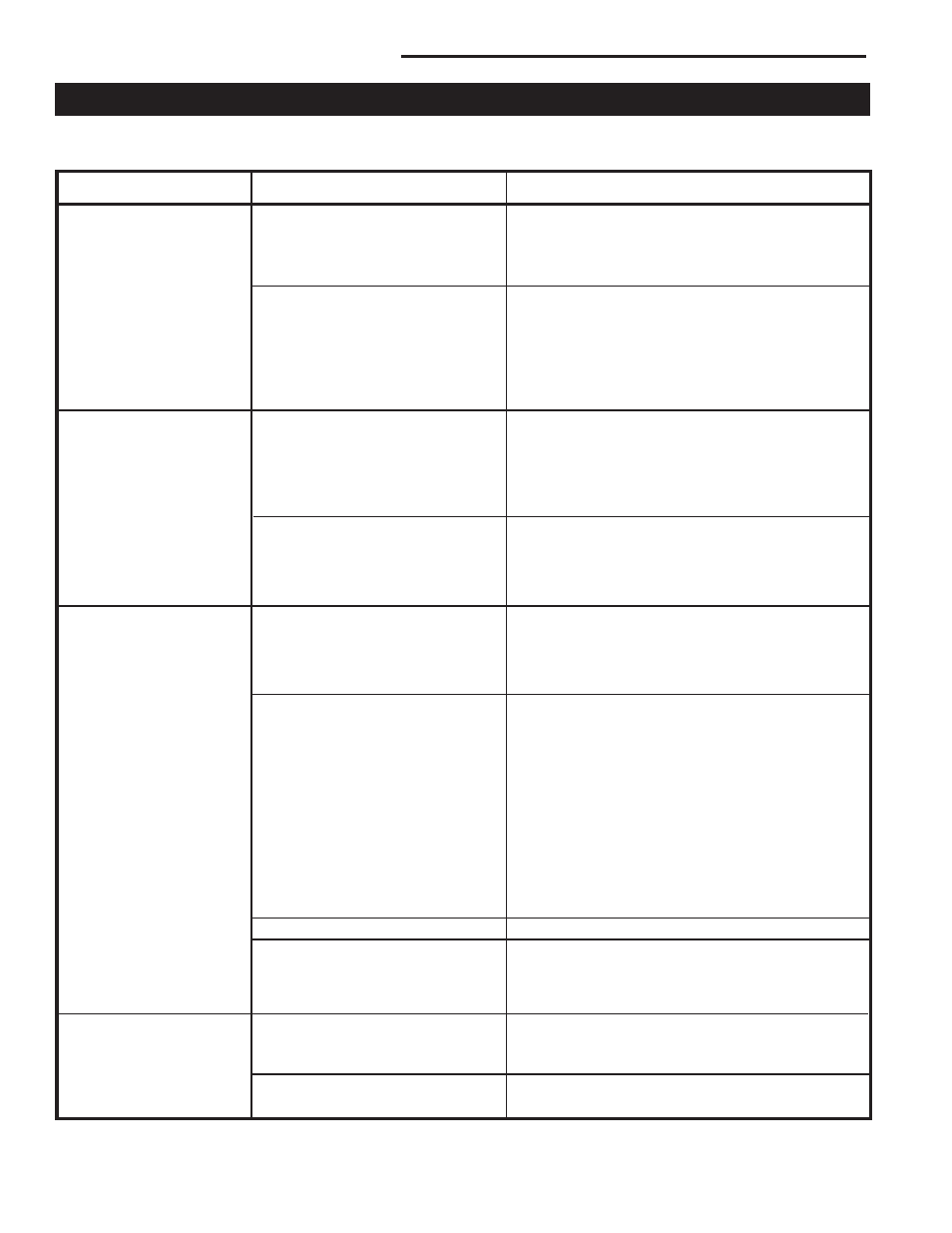

Troubleshooting the Gas Control System (SDDVT Series)

NOTE: Before trouble shooting the gas control system, be sure external gas shut off is in the “On” position.

SIT NOVA 820 MILLIVOLT VALVE

Symptom

1. Spark ignitor will not light

2. Pilot will not stay lit after

carefully following lighting

instructions

3. Pilot burning, no gas to

main burner

4. Frequent pilot outage

problem

Possible Causes

A. Defective or misaligned electrode

at pilot

B. Defective ignitor (Push Button)

A. Defective pilot generator (thermo-

couple), remote wall switch

B. Defective automatic valve

A. Wall switch or wires defective

B. Thermopile may not be generat-

ing sufficient millivoltage

C. Plugged burner orifice

D. Defective automatic valve opera-

tor

A. Pilot flame may be too low or

blowing (high) causing the pilot

safety to drop out

B. Possible blockage of the vent

terminal

Corrective Action

Using a match, light pilot. If pilot lights, turn off pilot and

push the red button again. If pilot will not light - check

gap at electrode and pilot-should be 1/8” to have a

strong spark.

With the control knob in the pilot position, push the

control knob all the way and hold. Check for spark at

electrode and pilot. If no spark to pilot, and electrode

wire is properly connected, replace the battery in the

ignitor module and try again. Refer to Maintenance

Section. If the problem still exists, replace the ignitor

module box.

Check pilot flame. Must impinge on thermocouple/ther-

mopile. NOTE: This pilot burner assembly utilizes both

a thermocouple and a thermopile. The thermocouple

operates the main valve operation (On and Off). Clean

and or adjust pilot for maximum flame impingement on

thermopile and thermocouple.

Turn valve knob to “Pilot”. Maintain flow to pilot; millivolt

meter should read greater than 10mV. If the reading

is okay and the pilot does not stay on, replace the gas

valve. NOTE: An interrupter block (not supplied) must

be used to conduct this test.

Check wall switch and wires for proper connections.

Jumper wire across terminals at wall switch, if burner

comes on, replace defective wall switch.. If okay,

jumper wires across wall switch wires at valve, if burner

comes on, wires are faulty or connections are bad.

1. Be sure wire connections form thermopile at gas

valve terminals are tight and thermopile is fully

inserted into pilot bracket.

2. One of the wall switch wires may be grounded. Re-

move wall switch wires form valve terminals if pilot

now stays lit, trace wall switch wiring for ground.

May be grounded to fireplace or gas supply.

3. Check thermopile with millivolt meter. Take reading

at thermopile terminals of gas valve. Should read

250-300 millivolts (minimum 150) while holding

valve knob depressed in pilot position and wall

switch “Off”. Replace faulty thermopile if reading is

below specified minimum.

Check burner orifices for debris and remove.

Turn valve knob to “On”, place wall switch to “On”

millivolt meter should read greater than 150mV. If the

reading is okay and the burner does not come on,

replace the gas valve.

Clean and/or adjust pilot flame for maximum flame

impingement on thermopile and thermocouple.

Check the vent terminal for blockage (recycling the flue

gases).