Stardance direct vent - rear vent gas heaters – Vermont Casting SDDVRBS User Manual

Page 26

26

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

�����

������������������������

����

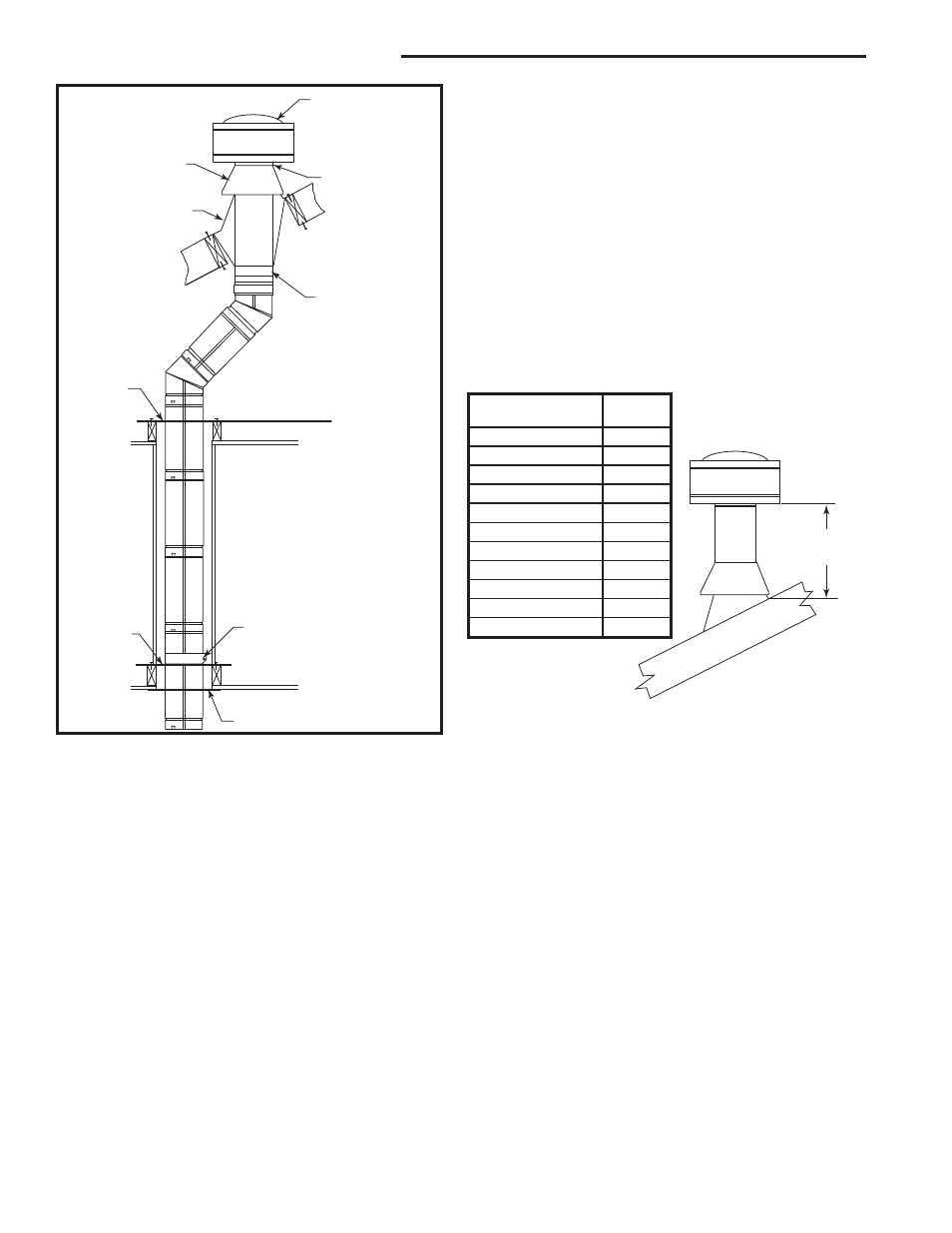

Vertical Termination

Approved Silicone

Sealant Here

Storm Collar

Flashing

Offset Support

Collar

Firestop

Spacer

Ceiling Support Collar

Ceiling

Support

Plate

Trim Plate

ST933

Fig. 46 Typical vertical venting configuration.

6. Install the ceiling support cathedral ceiling support

box assembly, as appropriate.

7. Determine the distance from the appliance outlet to

a point just above [approximately 12” (305 mm) to 24”

(610 mm)] either the cathedral ceiling support box or

the ceiling support plate and assemble lengths of pipe

to satisfy this distance. Do not attach assembly to appli-

ance.

8. Loosely position the support collar around the as-

sembled lengths (flared end down).

9. From above, lower the assembled pipe sections

down through the cathedral ceiling box or ceiling sup-

port plate and attach it to the appliance adapter. The

support collar should then be adjusted so that when

the assembled lengths of pipe are attached to the ap-

pliance, it rests on the bottom of the cathedral ceiling

support box on top of the ceiling support plate.

10. Tighten the tabs of the collar. Secure the sup-

port collar by inserting three (3) #8 x 1/4” sheet metal

screws through the support collar and the outer wall of

the pipe.

NOTE: If the cathedral ceiling support box assembly is

being used, it may be necessary to temporarily connect

the assembled pipe to the appliance. Determine and

mark the location of where the support collar will be at-

tached to the pipe. Disconnect and remove assembled

pipe. Attach the support collar per Step 10 (where

marked) and reinstall assembly. This is due to limited

space within the cathedral ceiling support box. Install

any required offset supports.

11. Add lengths of pipe and firestop as necessary

until assembly extends to a point above the roof which

complies with local code requirements for minimum ter-

mination height and with the appliance manufacturer’s

installation instructions. (Fig. 47)

Minimum Height

Above Roof

ST934

minimum height

6/07

Minimum

Roof Pitch

Height

Flat to 7/12

1’0”

Over 7/12 to 8/12

1’6”

Over 8/12 to 8/12

2’0”

Over 9/12 to 10/12

2’6”

Over 10/12 to 11/12

3’3”

Over 11/12 to 12/12

4’0”

Over 12/12 to 14/12

5’0”

Over 14/12 to 16/12

6’0”

Over 16/12 to 18/12

7’0”

Over 18/12 to 20/12

7’6”

Over 20/12 to 21/12

8’0”

Fig. 47 Minimum Height Above Roof Requirements

NOTE: Whenever DIRECT-TEMP penetrates through a

ceiling, a floor or a wall, it must be firestopped.

12. Using a level, make sure the system is perfectly

vertical.

13. Slide the flashing, suitable for the roof pitch, down

over the pipe protruding through the roof. Recheck

orientation and use a silicone sealant around and under

the perimeter of the flashing where it is in contact with

the roof. Secure the flashing with roofing nails. Finish

roofing around the pipe, covering the sides and upper

ares of the flashing base with roofing material. How-

ever, be sure the lower unnailed portion of the base

covers the roofing material.

14. Position the storm collar around the pipe and slide

down until it is in contact with the flashing. Secure the

storm collar by inserting the two (2) tabs into the raised

slots and fold tabs back. Seal the area between the

storm collar and the vent pipe with a silicone sealant to

prevent rain infiltration.

15. Install the vertical termination (VC) by inserting it

down into the top most section of pipe until it is fully