Stardance direct vent - rear vent gas heaters, Venting system assembly general information, Rear vent – Vermont Casting SDDVRBS User Manual

Page 15

15

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

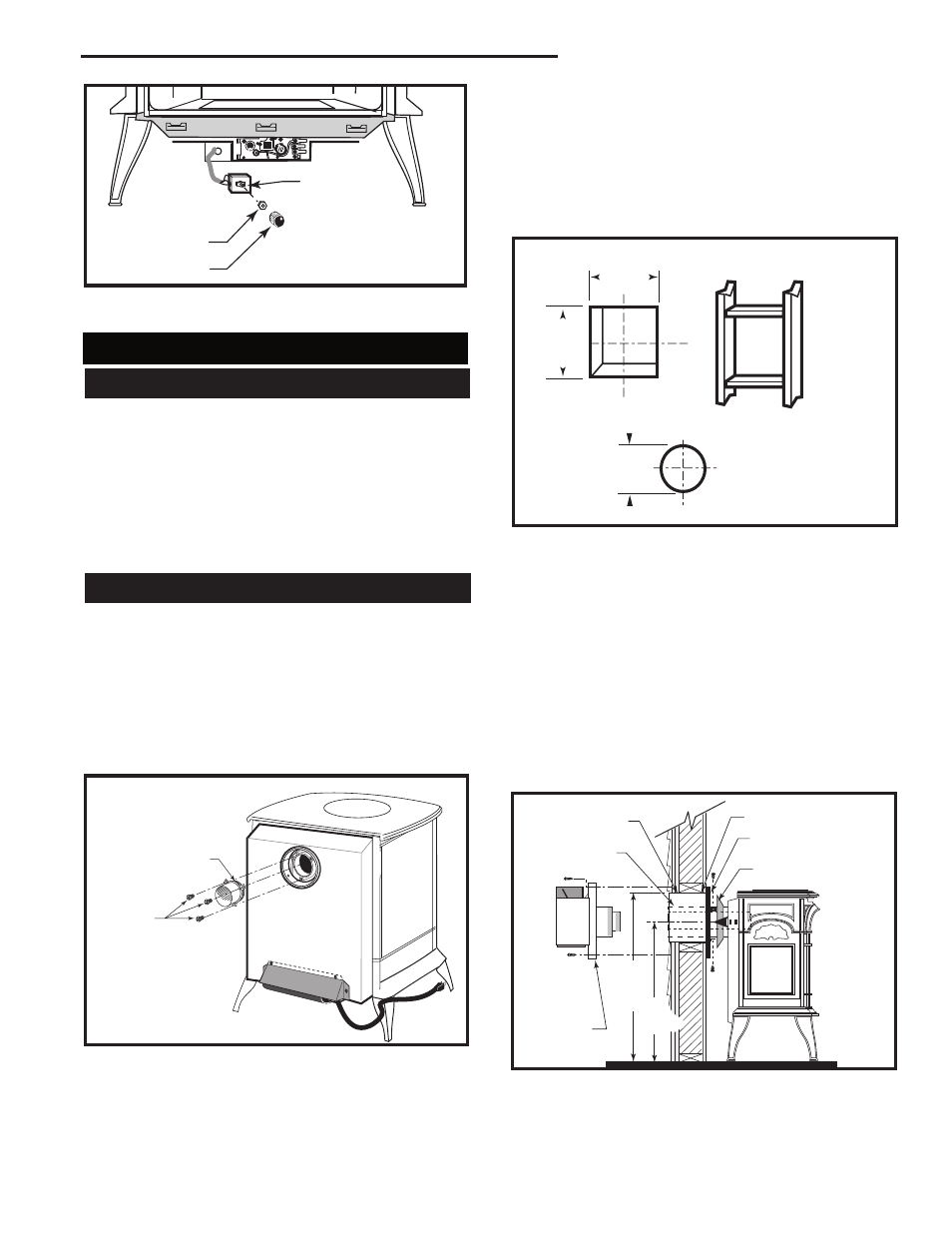

2. Locate the vent opening on the wall. Refer to Fig-

ures 18 & 19 to determine the top of the opening

centerline. It may be necessary to first position the

stove and measure to find the hole location. De-

pending on whether the wall is made of combustible

materials, cut the opening to the size shown in Fig-

ure 18. Combustible wall openings must be framed

as shown in Figure 18.

ST477

rear vent kit

6/00

27���"

(695mm)

to Top of

Opening

CL

22���”

(565 mm)

Firestop

Ventilated Wall Plate

- Open End Down

Finishing Collar

Seal

Around

Terminal

9³⁄₈” W x 10³⁄₈” H

Wall Opening

ST477

Wall Sleeve

- Seal Around

Fig. 19 Rear Vent Kit 7TFSRSK installation.

VO584-100

Vent Opening

2/99 djt

9³⁄₈"

(240mm)

9³⁄₈"

(240mm)

7¹⁄₂"

(191mm)

VO584-100

Fig. 18 Locate vent opening.

Framing Detail

Vent Opening - Combustible Wall

Vent Opening -Noncombustible Wall

Venting System Assembly

General Information

The Stardance is approved for installation only with the

vent components listed on Pages 12 & 13. Follow the

vent component instructions exactly.

For U.S. installations: The venting system must con-

form with local codes and/or the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54

For Canadian installations: The venting system must

conform to the current CSA B149.1 installation code.

Rear Vent

Use Rear Vent Kit 7TFSRSK for an installation where

the heater is parallel to the wall and the vent system

extends straight back through that wall.

1. Attach Inner Starter Pipe, (found in with the logset),

to the stove.

•

Run a bead of sealant beneath the pipe bead and

attach to the stove using three 1/4-20 x 3/8” phillips

screws provided in the parts bag. (Fig. 17)

�����

������������

������������

����

Sealant

Phillips

Screws

ST937

Fig. 17 Apply sealant to the starter pipe, and fasten to stove

with Phillips screws.

ST347a

JUV

FK28

rheostat install

9/21/00

Rheostat

Retaining Nut

Rheostat Knob

FK104

Fig. 16 Attach rheostat to bracket.

3. Measure the wall thickness and cut the wall sleeve

sections to proper length (MAXIMUM 12”). Assemble

the sleeve with the #8 sheet metal screws supplied.

Attach the firestop plate to the sleeve end with the

holes. (Fig. 24) NOTE: The wall sleeve is required in

combustible walls only.

4. Install the Wall Firestop/Sleeve assembly into the

wall cutout and fasten the firestop to the wall cutout

framing members. (Figs. 19)

5. Measure, and cut if necessary, the appropriate

length of pipe section needed to make the connec-

tion through the wall.