Stardance direct vent - rear vent gas heaters – Vermont Casting SDDVRBS User Manual

Page 17

17

Stardance Direct Vent - Rear Vent Gas Heaters

20012950

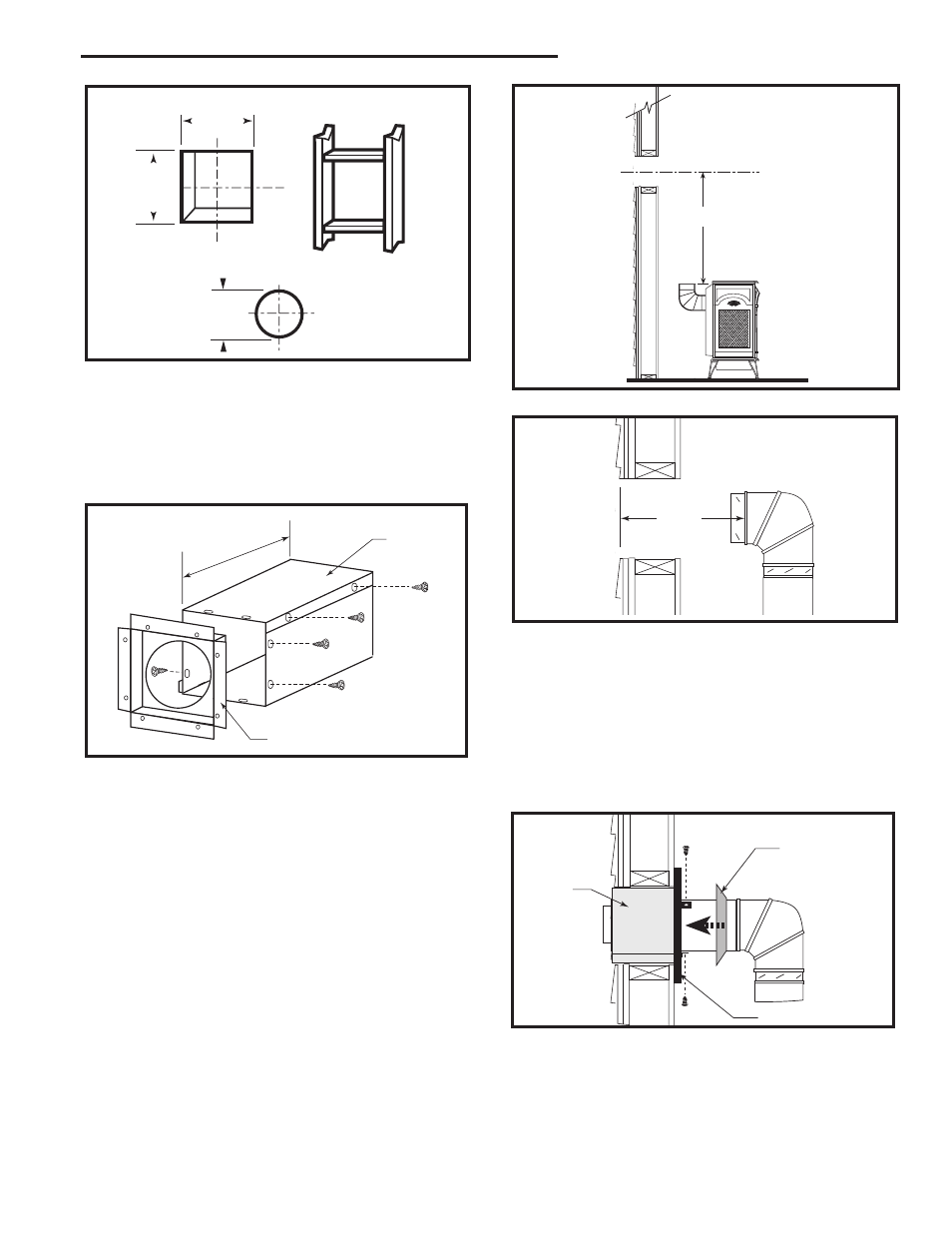

Fig. 23 Locate vent opening.

VO584-100a

VO584-100

Vent Opening

2/99 djt

9³⁄₈"

(240mm)

9³⁄₈"

(240mm)

7¹⁄₂"

(191mm)

Vent Opening - Combustible Wall

Vent Opening - Noncombustible Wall

ZCS103

Zero Clearance Sleeve

& Firestop

12/6/99 djt

12”

(305mm)

Max. Length

Sleeve

#8 Sheet

Metal Screws

Firestop

ZCS103

Fig. 24 Assemble the wall sleeve and firestop.

Attach the firestop plate to the sleeve end with the

holes. (Fig. 24) NOTE: The wall sleeve is required

in combustible walls only.

3. Install the Wall Firestop/Sleeve assembly into the

wall cutout and fasten the firestop to the wall cutout

framing members. (Fig. 24)

8. Slip the wall plate and trim collar over the interior

end of the horizontal pipe and install into the wall

sleeve. Seal the joint inside the wall plate if needed

to keep cold air from being drawn into the home.

9. Connect the horizontal pipe to the elbow. Fasten the

wall plate to the pipe with three sheet metal screws.

Slide the trim collar up against the wall plate to cover

the screws. (Fig. 27)

ST214

measure vertical vent

12/6/99 djt

X

Fig. 25 Determine the vertical pipe length.

ST478

ST216

install pipe thru wall

12/6/99 djt

Trim Collar

Wall

Sleeve

Wall Plate

ST216

Fig. 27 Install the horizontal pipe and wall plate parts.

ST215

measure thru wall

12/6/99 djt

X

ST215

Fig. 26 Measure the horizontal length.

4. If necessary, measure to determine the vertical

length (X) of pipe required from the first (transition)

elbow to the wall cutout centerline, including a 2”

overlap at the joint. (Fig. 25) Use a hacksaw or tin

snips to trim the pipe as needed.

5. Install first the inner then the outer straight pipe

section(s), trimmed end down, to the point of the el-

bow. Drill 3 holes through each joint and fasten with

sheet metal screws.

6. Install the elbow using 3 sheet metal screws at each

joint.

7. Measure, and cut if necessary, the appropriate

length of pipe section needed to make the connec-

tion through the wall. Include a 2” overlap; i.e. from

the elbow to the outside wall face, about 2” or the

distance required if installing a second 90° elbow.

(Fig. 26)