Tomei Powered ARMS M8280 User Manual

Page 28

To work out the injector sizes you need you use this formula,

Target Horsepower x 5.9 ÷ No. of Cylinders = the cc flow amount per cylinder required.

Take into account that you will run up to 80%~90% of the injector’s capacity.

240ℓ/h Or Higher (Fuel Pressure 3kg/㎠)

Recommended: TOMEI 255ℓ/h (Fuel Pressure 3kg/㎠)

To work out the fuel pump size you need you use this formula,

Injectors Capacity x No. of Cylinders x 0.06 = Fuel Pump flow rate required.

Then consider that the fuel pump should be used at 80~90% capacity when making your choice.

Changing the fuel pump will require you to adjust the fuel pressure with an adjustable fuel

pressure regulator to suit the new setup. You will need to set it at 3k when idling without

the vacuum hose being connected.

Choose the right high flow air filter to suit your power target.

The stock airflow sensor is capable for up to 500ps.

When running at higher boost, the stock suction pipe is not strong enough, so deformation occurs.

You can improve the intake efficiency by upgrading it. However, when taking advantage of the

straight airflow method, idling will become rougher and it will be easier to stall the engine.

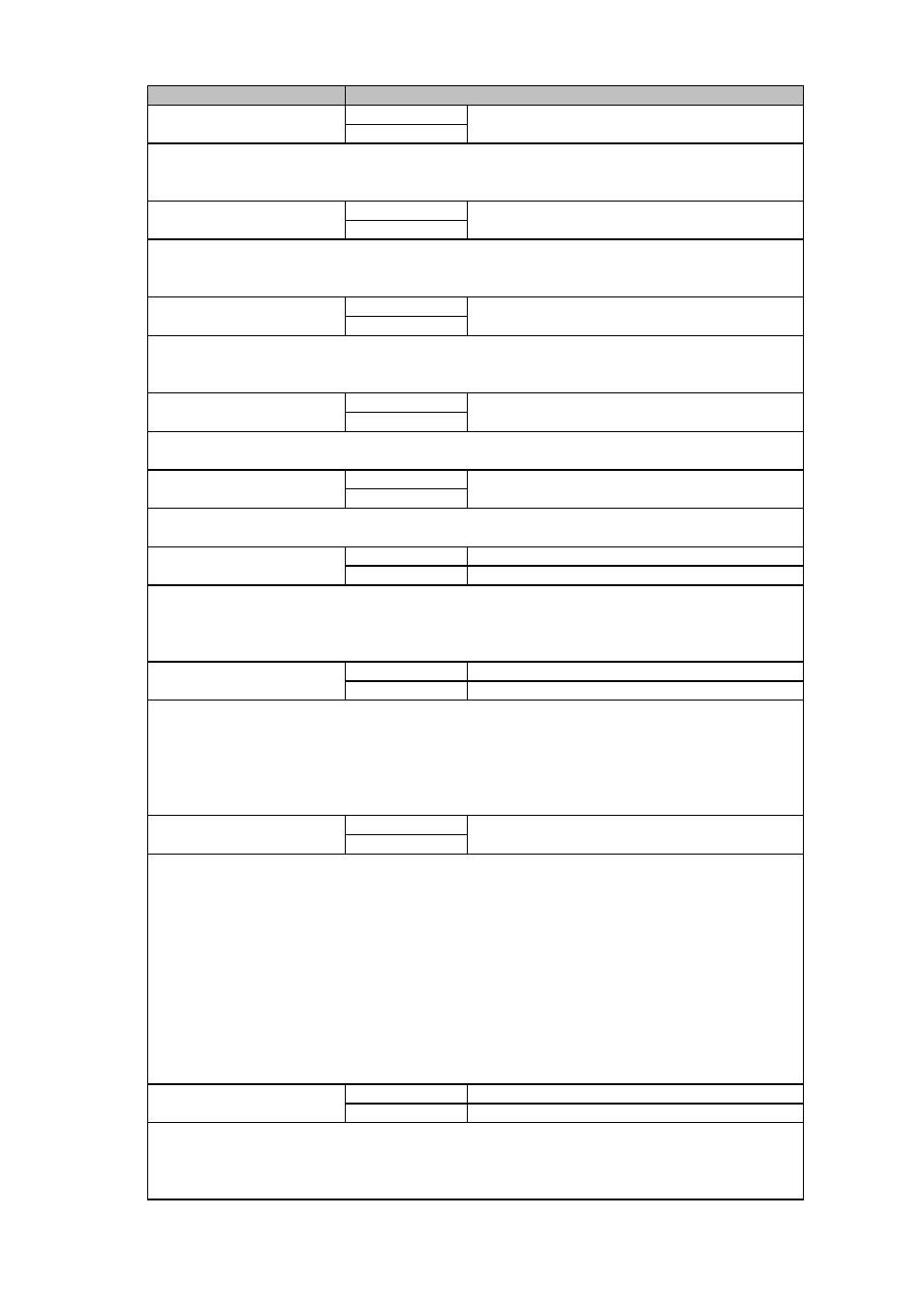

AIR CLEANER

STOCK CONDITION

High Flow Type

TUNED ENGINE

AIR FLOW SENSOR (MAF)

STOCK CONDITION

Stock Air Flow Meter or Without

TUNED ENGINE

ITEMS

RECOMMENDED SETUP

INJECTORS

STOCK CONDITION

550cc Or Higher

TUNED ENGINE

TUNED ENGINE

Upgrade Required, Recommended: TOMEI type-S

STOCK CONDITION

FUEL PRESSURE REGULATOR

TUNED ENGINE

STOCK CONDITION

FUEL PUMP

SUCTION PIPE

STOCK CONDITION Stock bolt on replacement, or standard.

TUNED ENGINE

STRAIGHT PIPE

28

Pressurized air from the Turbine is compressed and sent to the engine. This process forces the air

temperature to increase with heat. So when it does, the air density drops and combustion efficiency

becomes poor, resulting to performance loss. The intercoolers job is then to extract the heat from

the forced air via the fins in the intercooler. This again helps compress the air again, and the

denser colder air will improve combustion efficiency to optimize performance.

When the throttle is suddenly closed, the forced air from the Turbine will have no where to go.

This restricted flow places a heavy burden on the turbo and other parts. So the Blow Off Valve is

fitted somewhere between the turbo and the throttle to prevent this problem by giving an option of

an escape route to vent the excess pressure. This saves the turbo from any possible problems. The

stock BOV was never designed to handle high boost applications, so it will struggle to do it's job

properly when the limits are exceeded. This puts the turbo at risk of failure and response drops.

This is why we recommend to upgrade the BOV to a stronger type. Additionally, when the BOV is a

vent to atmosphere type, this can. This is why we recommend to upgrade the BOV to a stronger type.

Additionally, when the BOV is a vent to atmosphere type, this can cause other problems with the

flowing into the engine. ECU not being able to read correct air volume that is flowing through it.

As the volume of air still passes through the air flow meter but not all of if goes to the engine. In

this case the air to fuel mixture will be incorrect. So we recommend the recirculation type design.

By upgrading your camshafts, you can increase the exhaust pressure, this in turn will help

spool larger turbines efficiently once the exhaust manifold has also been changed. All together

will aid with the performance increase. Then your larger Turbine will be able to come on boost

faster.

STOCK CONDITION

Recommended: Strenghtened Type (Recirculation)

TUNED ENGINE

EXHAUST MANIFOLD

STOCK CONDITION NORMAL

TUNED ENGINE

Large capacity, high flow type.

INTERCOOLER

STOCK CONDITION Stock Replacement Upgrade, or stock.

TUNED ENGINE

Large capacity, high flow type.

BLOW OFF VALVE

(Recirculation Type)

28