Carrier AQUAZONE 50RTP03-20 User Manual

Page 46

46

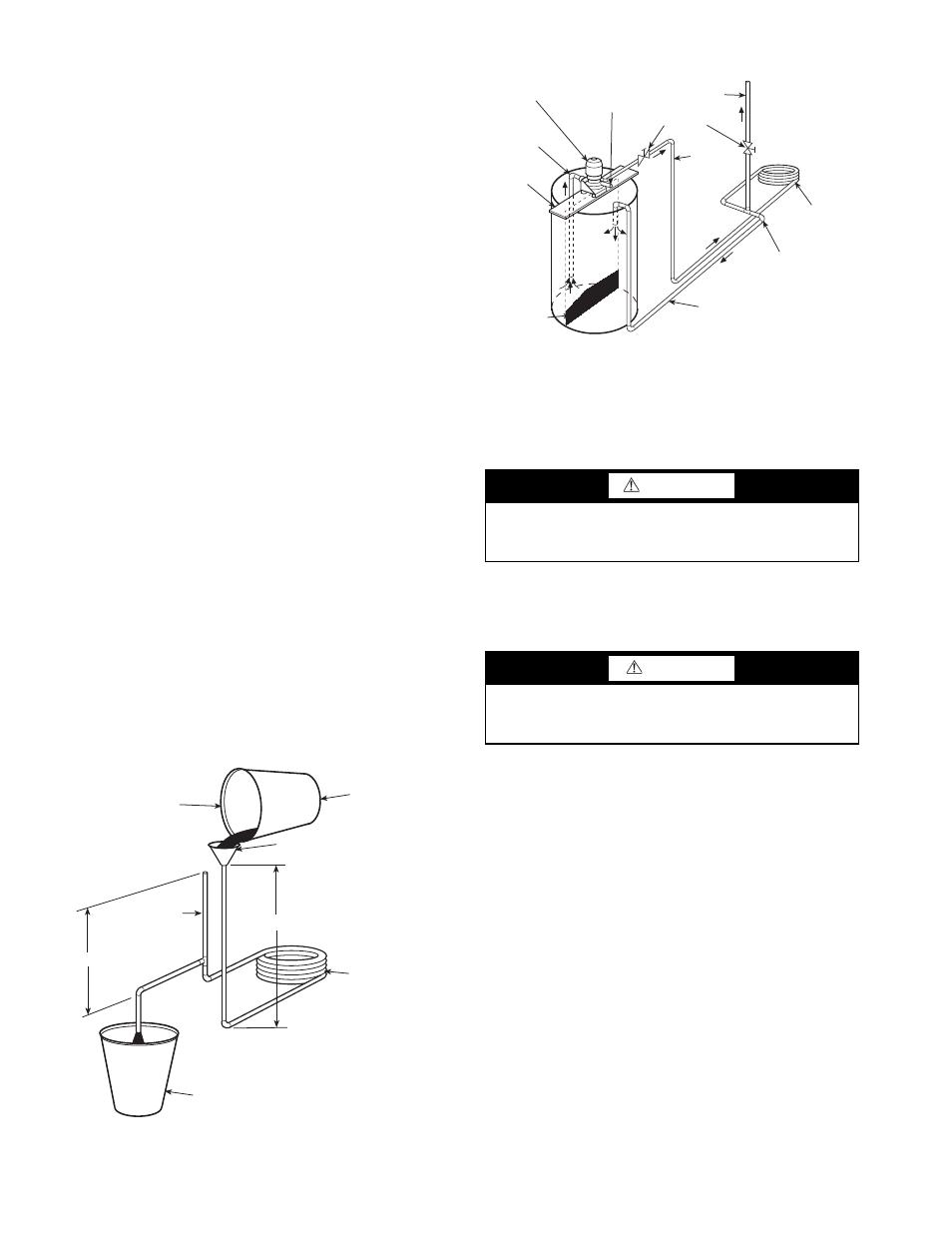

Clean condensers with an inhibited hydrochloric acid solu-

tion. The acid can stain hands and clothing, damage concrete,

and, without inhibitor, damage steel. Cover surroundings to

guard against splashing. Vapors from vent pipe are not harmful,

but take care to prevent liquid from being carried over by the

gases.

Warm solution acts faster, but cold solution is just as effec-

tive if applied for a longer period.

GRAVITY FLOW METHOD — Do not add solution faster

than vent can exhaust the generated gases.

When condenser is full, allow solution to remain overnight,

then drain condenser and flush with clean water. Follow acid

manufacturer’s instructions. See Fig. 23.

FORCED CIRCULATION METHOD — Fully open vent

pipe when filling condenser. The vent may be closed when

condenser is full and pump is operating. See Fig. 24.

Regulate flow to condenser with a supply line valve. If

pump is a nonoverloading type, the valve may be fully closed

while pump is running.

For average scale deposit, allow solution to remain in con-

denser overnight. For heavy scale deposit, allow 24 hours.

Drain condenser and flush with clean water. Follow acid manu-

facturer’s instructions.

Checking System Charge —

Units are shipped with

full operating charge. If recharging is necessary:

1. Insert thermometer bulb in insulating rubber sleeve on

liquid line near filter drier. Use a digital thermometer for

all temperature measurements. DO NOT use a mercury

or dial-type thermometer.

2. Connect pressure gage to discharge line near compressor.

3. After unit conditions have stabilized, read head pressure

on discharge line gage.

NOTE: Operate unit a minimum of 15 minutes before

checking charge.

4. From standard field-supplied Pressure-Temperature chart

for R-410A, find equivalent saturated condensing

temperature.

5. Read liquid line temperature on thermometer; then

subtract from saturated condensing temperature. The dif-

ference equals subcooling temperature.

6. ADD refrigerant to raise the temperature or REMOVE

refrigerant (using standard practices) to lower the temper-

ature (allow a tolerance of ± 3° F), as required.

Refrigerant Charging

NOTE: Do not vent or depressurize unit refrigerant to atmo-

sphere. Remove and recover refrigerant following accepted

practices.

Air Coil Fan Motor Removal

Motor power wires need to be disconnected from motor

terminals before motor is removed from unit.

1. Shut off unit main power supply.

2. Loosen bolts on mounting bracket so that fan belt can be

removed.

3. Loosen and remove the 2 motor mounting bracket bolts

on left side of bracket.

4. Slide motor/bracket assembly to extreme right and lift out

through space between fan scroll and side frame. Rest

motor on a high platform such as a step ladder. Do not

allow motor to hang by its power wires.

Replacing the WSHP Open Controller’s Bat-

tery —

The WSHP Open controller’s 10-year lithium

CR2032 battery provides a minimum of 10,000 hours of data

retention during power outages.

NOTE: Power must be ON to the WSHP Open controller

when replacing the battery, or the date, time and trend data will

be lost.

1. Remove the battery from the controller, making note of

the battery's polarity.

2. Insert the new battery, matching the battery's polarity

with the polarity indicated on the WSHP Open controller.

FILL CONDENSER WITH

CLEANING SOLUTION. DO

NOT ADD SOLUTION

MORE RAPIDLY THAN

VENT CAN EXHAUST

GASES CAUSED BY

CHEMICAL ACTION.

PAIL

FUNNEL

CONDENSER

PAIL

3’ TO 4’

VENT

PIPE

5’ APPROX

1”

PIPE

Fig. 23 — Gravity Flow Method

WARNING

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system —

this can cause compressor flooding.

CAUTION

Before attempting to remove fan motors or motor mounts,

place a piece of plywood over evaporator coils to prevent

coil damage.

SUCTION

PUMP

SUPPORT

TANK

FINE MESH

SCREEN

RETURN

GAS VENT

PUMP

PRIMING

CONN.

GLOBE

VALVES

SUPPLY

1” PIPE

CONDENSER

REMOVE WATER

REGULATING VALVE

Fig. 24 — Forced Circulation Method