Calibrations for number of turns – Great Plains NTA2000D Operator Manual User Manual

Page 39

37

9/13/2006

NTA 2000D 148-632M

Great Plains Mfg., Inc.

11. If the result is different to the required rate, adjust the

Variator to increase or decrease the seeding rate. Re-

member to re-prime the feed mechanism with at least

50 turns before re-calibrating.

Note: Always move the Variator handle down to zero then

back up to the required setting.

Calibrations for Number of Turns

As indicated at the start of this section, accuracy in calibra-

tion can be affected by a number of factors not least of

which is soil type, wheel slip and sinkage. The number of

turns recommended for the calibration crank handle are

based on “average” figures in normal field conditions. If

farm conditions are very stony (so little sinkage) or very

sandy (so greater sinkage) then using the recommended

number of crank handle turns may be inaccurate.

To check the number of turns for individual field

conditions:

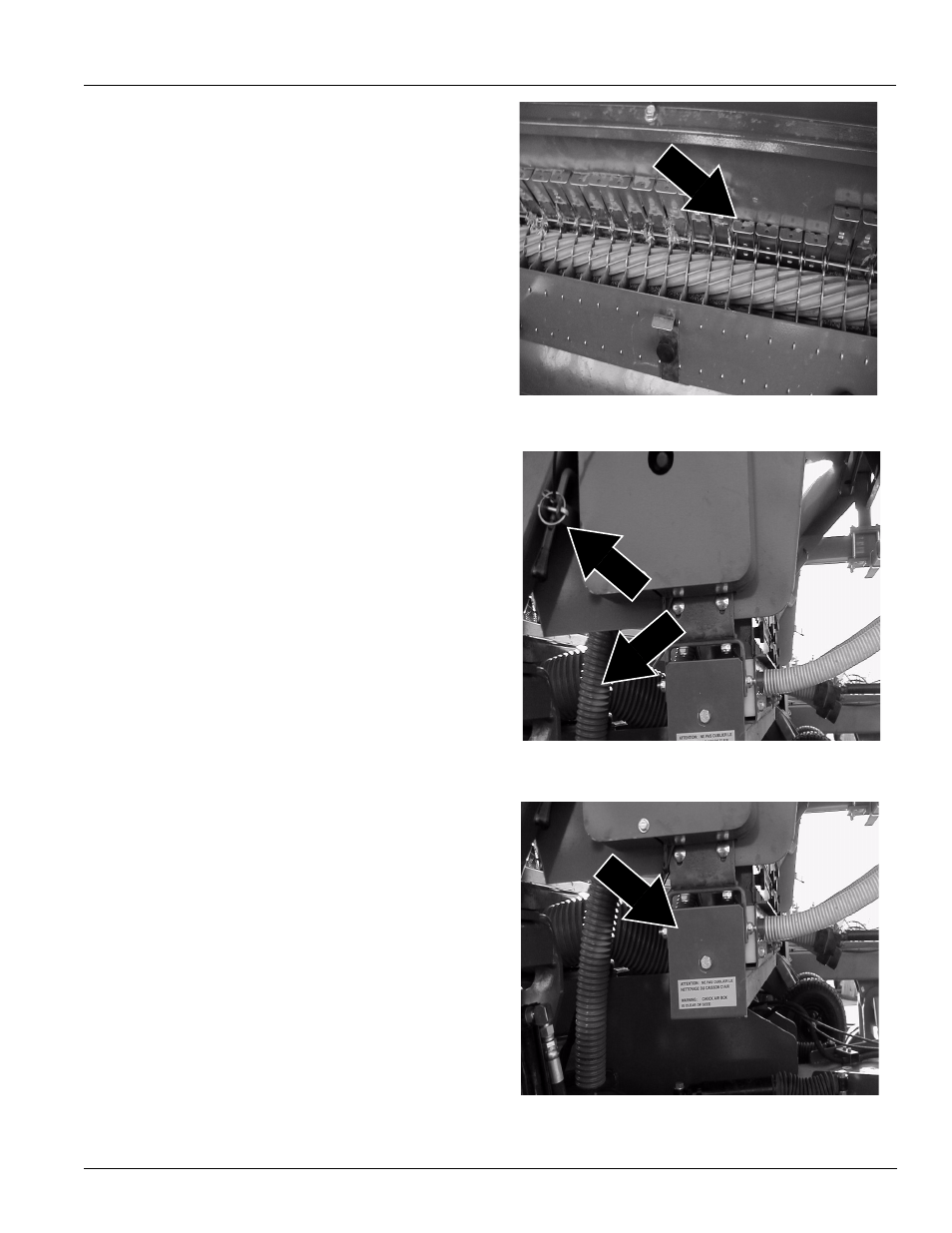

Refer to Figure 53

1.

Shut down the shut-off slide above each roller to pre-

vent seeding.

2.

Fill the drill half to two-thirds full of seed.

3.

Mark out 218 feet of seedbed.

4.

Position the calibration handle on the Variator input

and rotate to the upright (12 o’clock) position to give a

clear starting point.

5.

Drive the distance marked-off in the seedbed and

count the number of turns the calibration handle

makes.

6.

Note the number of turns and use this figure in the

Checking the Seeding Rate procedure in the previous

section in place of the standard.

Hopper Clean-out

Refer to Figure 54

The seed hopper has two slide gates connected to dis-

charge hoses for cleaning out the bulk of the seed from the

hopper. Each slide gate is controlled by a handle that

extends out beyond the end of the meter assembly. The

discharge hose can be directed into a bag or into the

auger hopper.

Final meter clean-cut must be done using the calibration

trays. Slide the venturi units forward and place the calibra-

tion trays under the feed rolls. Move the flap adjustment

handle to the full open position and empty the remaining

seed into the trays. The flap handle can be closed when

the trays are emptied.

Refer to Figure 55

The air distribution chamber must be inspected and keep

clean daily.

1.

Remove end caps and visually inspect chamber.

2.

To clean chamber, remove end caps and blow out

chamber with the fan.

Make sure the area around the openings is clear and that

no one will enter the area before starting fan.

Figure 54

Clean-out Handle

19938

Figure 55

Air Box End Cap

19936

Figure 53

Individual Shut Off

19934