Feed flaps half width shut-off – Great Plains NTA2000D Operator Manual User Manual

Page 37

35

9/13/2006

NTA 2000D 148-632M

Great Plains Mfg., Inc.

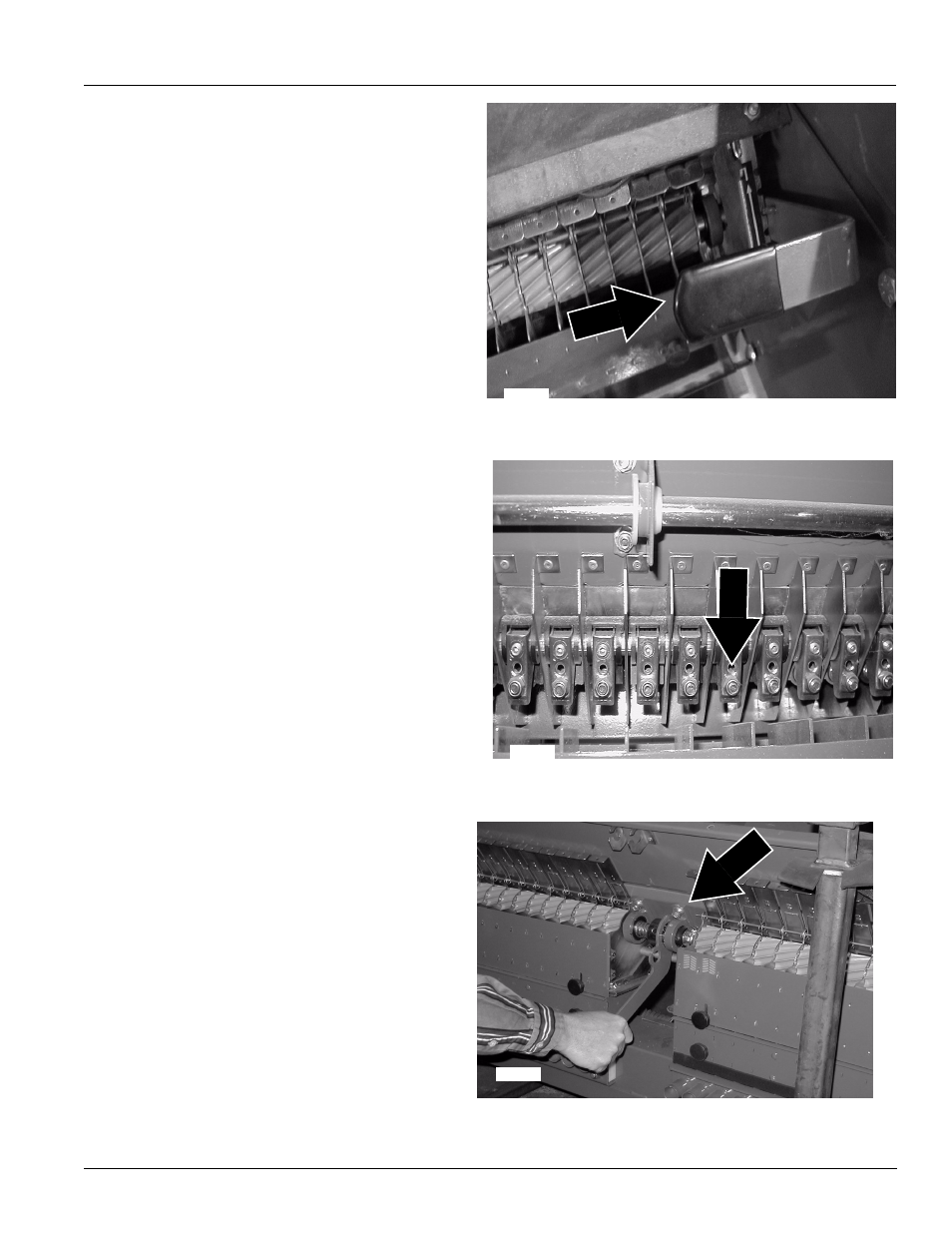

Figure 48

Half Width Clutch

Feed Flaps

Spring loaded flaps, one below each roller allows the

seeding of a wide range of seed sizes and are used to pos-

itively control the flow of small seeds to large seeds

through the feed rollers without causing bruising or crush-

ing. They also act as a safety devise for the feed rollers.

The spring loaded flap “gives” to allow a stone or other

obstructions through without damaging the rollers.

Refer to Figure 46

1.

The flaps under all the rollers are adjusted by a single

lever at the right hand end of the hopper. A series of

notches in the guide bracket set the lever to the re-

quired flap opening. Position 1 is the upper setting at

which the flaps are closest to the feed roller.

Refer to Figure 47

Note: Each flap should just touch the feed roller at position

1. This is factory set, however, if adjustment is required,

tighten or slacken the lock screw below the required flap to

keep all flaps equal across the meter.

The recommended position for the Feed Flap lever setting

for different seed types is as follows:

• Position 1: Small seeds e.g. rape, when the flap is

closest to the feed roller.

• Position 2: Cereals e.g. wheat and barley.

• Position 3: Large seeds e.g. peas and beans.

Note: Refer to the seed rate charts for proper feed flap set-

ting.

Half Width Shut-Off

Refer to Figure 48

Half width shut-off provides for:

a.

Seeding of a narrow width when finishing a field to

prevent double seeding.

b.

To start a field in the correct sequence when tram-

lining.

To disengage, insert tool into clutch grooves and rotate

the clutch until the two drive roll pins are in line. Slide

clutch to the left until the right drive roll pin is disengaged.

Rotate clutch one quarter turn back to lock it onto the left

drive roll pin to prevent the clutch from reengaging.

Note: The left- hand side of the feed mechanism is dis-

engaged. Re-engage by rotating the clutch from it’s lock

position and allow it to slide back to the right.

NOTE: CHECK TO BE SURE THE CLUTCH HAS

FULLY RE-ENGAGED.

19766

19922

19774

Figure 46

Feed Flap Adjustment

Figure 47

Feed Flap Adjustment Screw