Marker adjustments, 12 marker adjustments – Great Plains NTA2000D Operator Manual User Manual

Page 35

33

9/13/2006

NTA 2000D 148-632M

Great Plains Mfg., Inc.

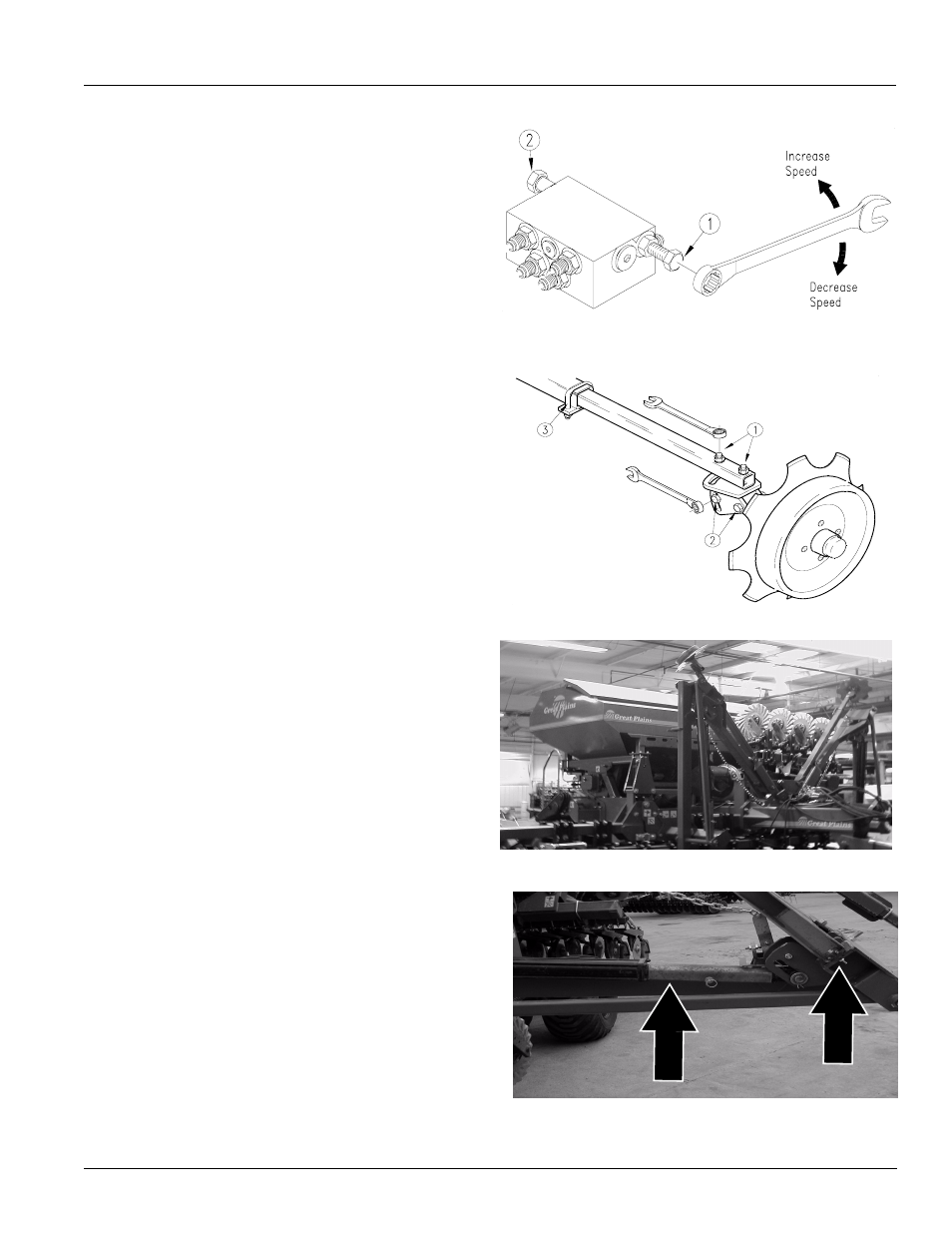

Figure 39

Speed Adjustment, Sequence Valve

Figure 40

Disk Angle

Figure 41

Marker Transport Position

Figure 42

Marker Field Position and Marker Breakaway Bolts

1

2

Marker Adjustments

Folding Speed

Refer to Figure 39

1.

Adjust folding speed with hex adjustment screws on

the sequence-valve body. There is one adjustment

screw for raising speed (1) and one for lowering speed

(2). Identify adjustment screws by markings stamped

in valve body.

2.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed.Turn adjustment

screws clockwise to decrease folding speed and

counterclockwise to increase folding speed. Exces-

sive folding speed could damage markers and void

the warranty.

3.

After adjusting the folding speed, tighten jam nuts on

hex adjustment screws to hold settings.

Disk Adjustments

Refer to Figure 40

If mark left by marker disk is not easy to see, change disk

angle to make a wider mark.

1.

Loosen two 1/2” carriage bolts (1) holding disk mount.

Rotate disk mount as desired.

If the marker disk is not square with the ground when the

marker is lowered in the field, or if marker arm tends to fold

up while lowered in the field, change disk angle relative to

ground.

2.

Loosen 1/2” bolts (2) and rotate marker mount until

marker disk is square with ground.

3.

To adjust where the disk marks, loosen U-bolt (3) and

slide marker-mount tube in or out as necessary. Re-

tighten U-bolt.

Cylinder Lock Channel

Refer to Figure 41

The markers should be in transport position when opening

a field or when drilling next to obstructions.

Refer to Figure 42

1.

For field operation the cylinder lock channels must be

placed on the cylinder rods so only the outer two sec-

tions of the markers fold. This speeds up marker cycle

time and reduces wear on markers.

2.

The markers have breakaway protection to keep them

from being damaged if the marker strikes a solid ob-

ject. The breakaway bolt should only be replaced with

a 3/8-16 x 2” Gr 5 bolt (Great Plains P/N 802-143C)

and two 3/8” nuts (Great Plains P/N 803-014C). It is

important to use two nuts on the breakaway bolt. Extra

bolts and nuts can be purchased and stored in the ex-

tra holes of the breakaway plate.

14048