12 maintenance overview, 10m press range maintenance overview – Great Plains P18140C Operator Manual User Manual

Page 37

37

8-10m Press Range

Operating Instructions

5. Servicing and Maintenance

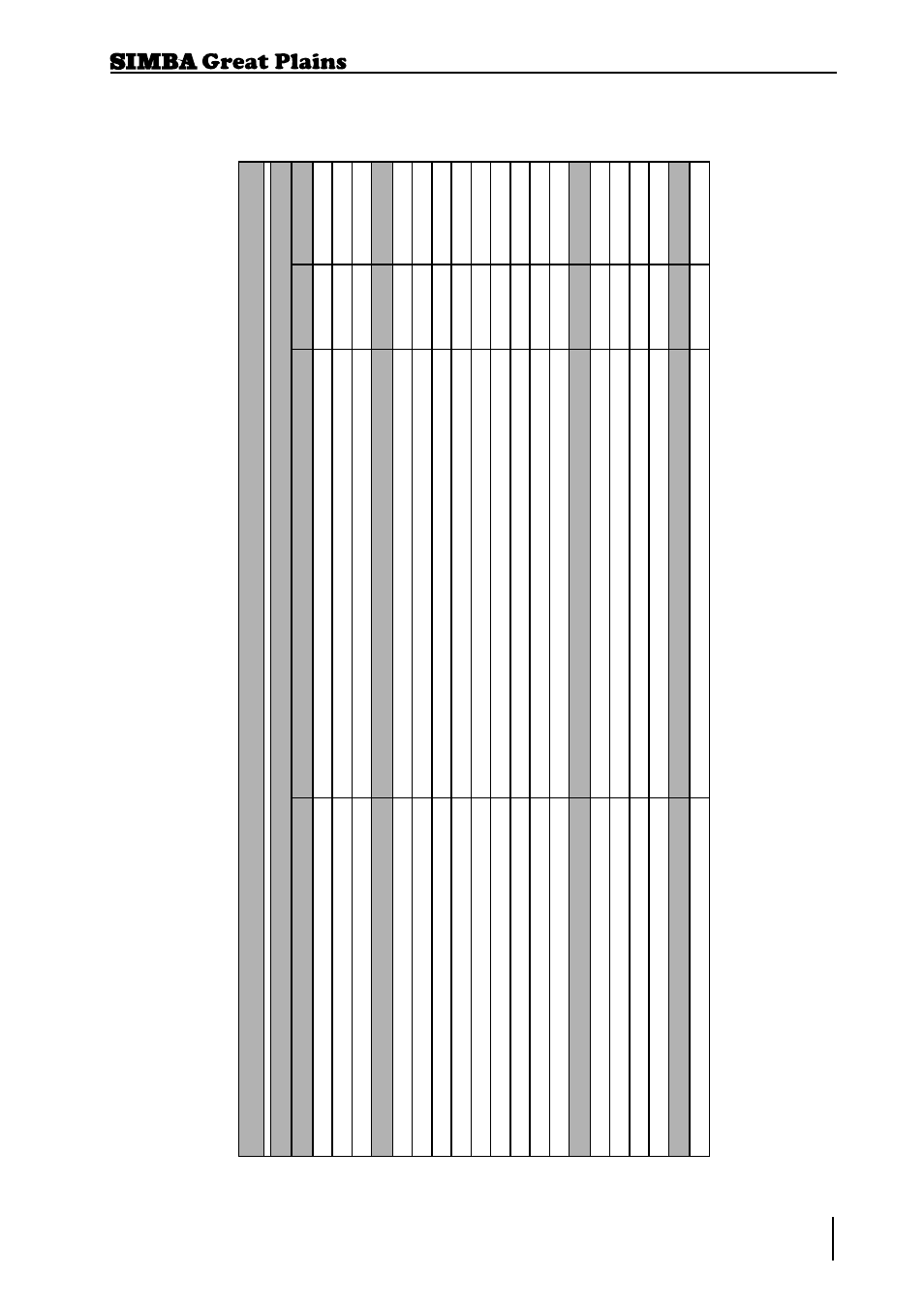

5.12 Maintenance Overview

8-10m Press Range Maintenance Overview

After first operation

Instructions

Interval

Note

Check all screw, bolt and plug connections

Check they are firmly seated. Tighten / Secure if necessary

---

---

Check wheel studs for tightness

Check on delivery and before transporting the machine

---

---

Lubricate machine

See overview of lubricating points

---

Page 38

During operation

Lubricate machine

See overview of lubricating points

---

Page 38

Wheel studs

Check tightness before transporting the machine

daily

---

Disc Angle, Working Depth (X-Press)

Check setting and ensure they are firmly secured

daily

Page 27, 29

Hydraulic system and components

Check seals, signs of crushing/wear, function and condition

daily

Page 35

Disc Bearings (X-Press)

Check condition, mountings and smooth operation

daily

Pages 24, 34

Levelling Boards

Check condition, mountings and smooth operation

daily

Pages 25, 28

Roll Axle bearings

Check condition, mountings and smooth operation

daily

Pages 25, 35

Double Disc roller ring segments

Check condition and ensure they are firmly secured

daily

Pages 25, 35

Safety devices (Transport Locks, chocks etc.)

Check condition and function

daily

---

After season

Lubricate machine

See overview of lubricating points

---

Page 38

Bolts / Lock Bolts

Grease any exposed threads

---

---

Entire machine

Carry out cleaning and maintenance

---

---

Spray Double Disc roll with oil

Use biological oil if possible - cover rubber elements

---

---

After 6 years

Hydraulic pipes

Replace

MRL Anh I

EN 1533