4 tines, 2 bearing seals – Great Plains P18140C Operator Manual User Manual

Page 34

8-10m Press Range

Operating Instructions

34

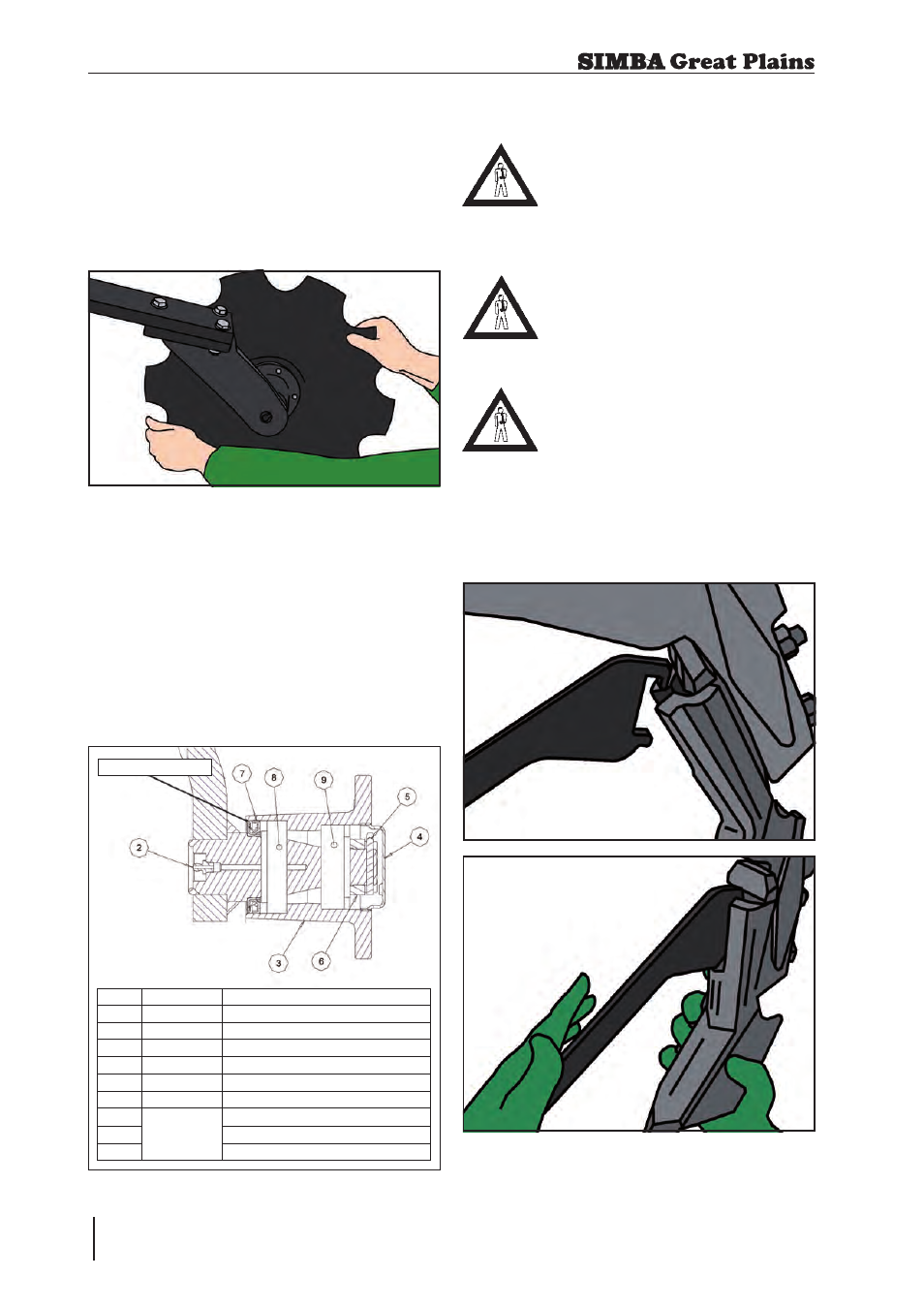

5.3.2 Bearing Seals

It is important when replacing the labyrinth

type bearing seals in disc hubs that the seal

is fitted the right way round. The chamfered

lip side should be at the outside of the

bearing housing, nearest the disc arm (see

Fig. 5.02). This chamfered lip prevents dirt

ingress into the housing and also allows

grease to be flushed though when greasing.

Fig. 5.02: Correct Seal Orientation

ITEM PART NO

DESCRIPTION

1

---

DISC ARM

2

P12900

NIPPLE - GREASE M8

3

P14593

HUB CASTING

4

P14594

HUB CAP

5

P12908

SPRING PIN

6

P12907

NUT CASTLE M27x1.5

7

SEAL 64x45x9.5

8

P12415

BEARING 32008 40x68x19

9

BEARING 32206 30x62x21

Chamfered Seal

6

Try to shake/rock the outer edge of the

hub/spindle: play of 0.1 / 0.2mm will

not reduce the bearings’ life and, in

addition, prevents overheating. If the

adjustment is correct the hub should

turn freely with the only friction being

from the seal.

Е

Е

Е

Е

Fig. 5.01: Checking Disc Bearing Adjustment

5. Servicing and Maintenance

5.4 Tines

When performing maintenance

work on tines extreme care

should be taken. Wear goggles

and gloves at at all times when

maintaining tines.

Safely support unfolded machine

in raised position using taps

and stands before attempting

maintenance work on tines.

Do not attempt to assist fitting tine

points with a steel headed hammer,

this can lead to splintering of the

metal due to its hardness, which

can cause injury. If tine fitting

requires assistance, a copper/

hide or plastic mallet should be

used.

Fig. 5.03: Knock-on Tine Point Removal Tool

STRIKE WITH

MALLET

ENGAGE POINT

REMOVAL TOOL