5 double disc axles, 6 wing pitch, 7 hydraulics – Great Plains P18140C Operator Manual User Manual

Page 35: 8 preparation for storage

35

8-10m Press Range

Operating Instructions

7. Parts and Assembly

5.5 Double Disc Axles

The axles on this roller are tensioned by the

main axle through the centre of the rings

and bearings.

Specialist equipment is required

for the disassembly of Double

Disc axles. Please consult your

dealer under any circumstances

that require disassembly of these

axles.

Maintenance of these rollers is limited to

daily greasing of the bearings to flush out

dirt, and regular inspection to ensure the

assemblies are tight, and scrapers are

correctly set. The axles can be tightened

provided the bearing pillar ‘U’ bolts are

loosened to avoid preloading the bearings

as they move sideways to each other.

Ensure the bearing pillars are re- tightened

to the mainframe after this.

5.6 Wing Pitch

The pitch of the wings can be altered

by using the threaded ends of the wing

cylinders. Tightening will raise the outer tips

of the wings and loosening will lower the tips

of the wings.

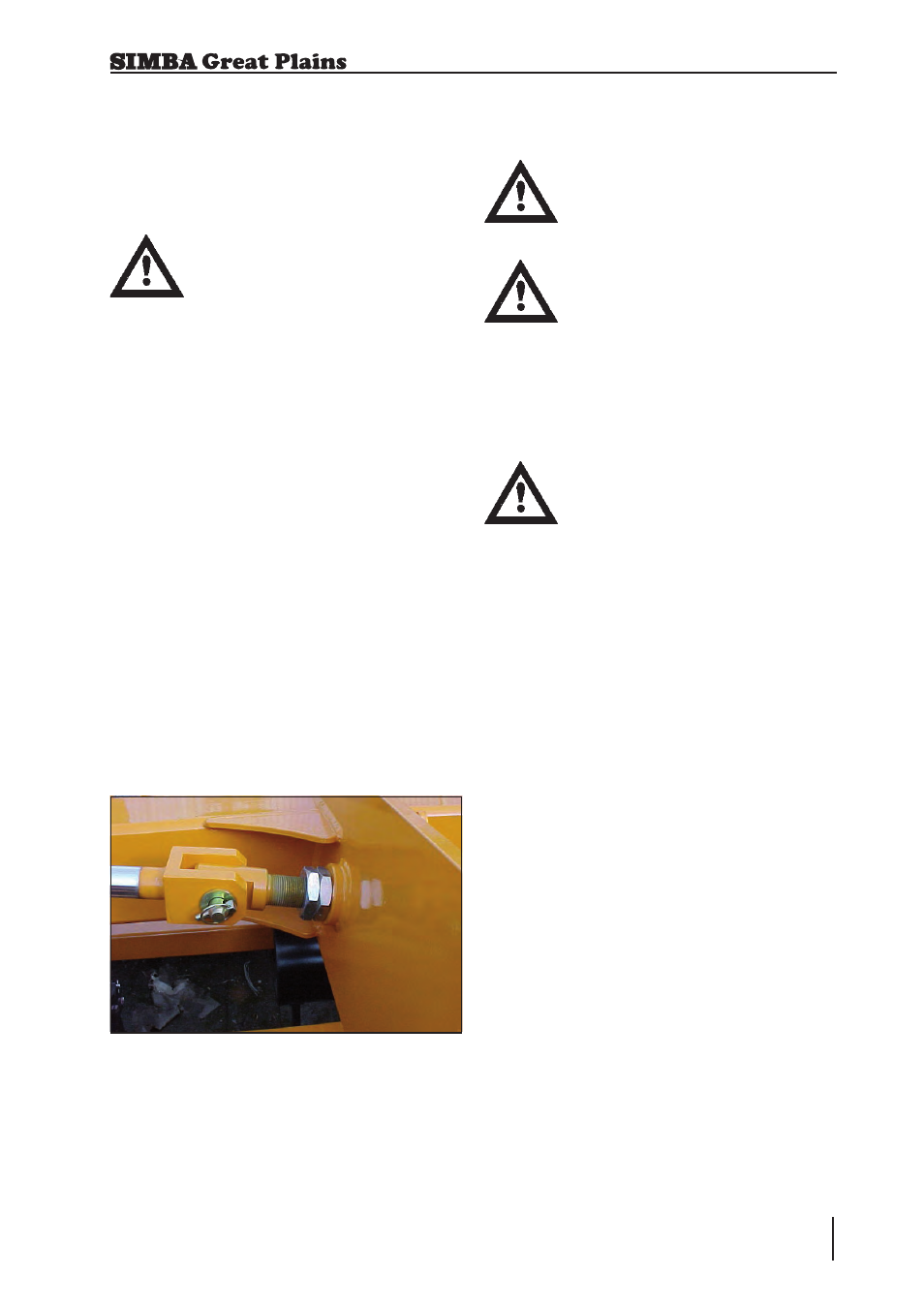

Fig. 5.04: Wing Pitch Adjustment

5.7 Hydraulics

A low oil flow should be used,

i.e., tractor tickover or low flow

selected.

The wing circuit is controlled by an

overcentre valve contained within

the manifold block which positively

locks oil flow until pressurised by

the tractor. System pressure can

be retained in the circuit even

after depressurisation of the

tractor quick release couplings.

Exercise extreme care when

checking the valve or circuits,

and under no circumstances

attempt to adjust or loosen fittings

without prior reference to your

authorised Simba Great Plains

dealer, and detailed maintenance

instructions.

5.8 Preparation for

Storage

If you need to store the machine for a longer

period, observe the following points:

• Park the machine undercover if possible.

• Protect the roll / discs against rust. If you

need to spray the implements with oil, use

light biologically degradable oils, e.g. rape

oil.